Preparation method of Tibetan medicine unique effervescent tablet

A unique and effervescent tablet technology, which is applied in pharmaceutical formulations, medical preparations containing active ingredients, drug delivery, etc., can solve the problems of pockmarked noodle product stability, long production cycle, and loss of active ingredients, and shorten production cycle, excellent placement stability, and increased stability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

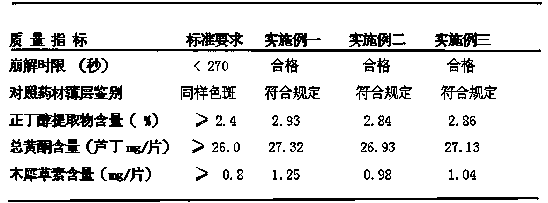

Embodiment 1

[0016] Preparation of Duyiwei extract: crush Duyiwei through a 40-mesh sieve, weigh 5 kg, soak in 60L of water as a solvent for 1.5 hours, then extract with an ultrasonic extractor at 35kHz, 60°C for 30min, and then filter to obtain a filtrate. The filter residue was then extracted with 50 L of water using an ultrasonic extractor at 35 kHz and 60° C. for 20 min, and filtered to obtain a secondary filtrate. The filter residue was extracted under the same conditions for the second time to obtain the third filtrate; the above three extracts were combined, concentrated under reduced pressure at 0.85Mpa at a vacuum degree of 60°C to an extract with a relative density of 1.20-1.30 (at 50°C); The extract was dried at a vacuum degree of 0.85Mpa at 60°C until the water content was less than 5.0%, and passed through an 80-mesh sieve to obtain 1228g of the extract. The content of n-butanol extract in the extract is 11.72%, the content of total flavonoids (calculated as rutin) is 11.68%, ...

Embodiment 2

[0030] Preparation of Duyiwei extract: crush Duyiwei through a 40-mesh sieve, weigh 10 kg, soak in 120L of water as a solvent for 2 hours, then extract with an ultrasonic extractor at 40kHz, 60°C for 40min, and then filter to obtain a filtrate. The filter residue was then extracted with 100 L of water using an ultrasonic extractor at 40 kHz and 60° C. for 30 min, and filtered to obtain a secondary filtrate. The filter residue was extracted under the same conditions for the second time to obtain the third filtrate; the above-mentioned three extractions were combined, and concentrated under reduced pressure at 0.85Mpa at a vacuum degree of 60°C to an extract with a relative density of 1.20-1.30 (at 50°C); The extract was dried at a vacuum degree of 0.855Mpa at 60°C until the water content was less than 5.0%, and passed through an 80-mesh sieve to obtain 2510g of the extract. The content of n-butanol extract in the extract is 11.95%, the content of total flavonoids (calculated as...

Embodiment 3

[0042] Preparation of Duyiwei extract: crush Duyiwei through 40 meshes, weigh 20 kg, soak in 240L water as solvent for 2 hours, then extract with an ultrasonic extractor at 40kHz, 60°C for 50min, and then filter to obtain a filtrate. The filter residue was then extracted with 200 L of water using an ultrasonic extractor at 40 kHz and 60° C. for 40 min, and filtered to obtain a secondary filtrate. The filter residue was extracted under the same conditions for the second time to obtain the third filtrate; the above three extracts were combined, concentrated under reduced pressure at 0.85Mpa at a vacuum degree of 60°C to an extract with a relative density of 1.20-1.30 (at 50°C); The extract was dried at a vacuum degree of 0.855Mpa at 60°C until the water content was less than 5.0%, and passed through an 80-mesh sieve to obtain 5110g of the extract. In the extract, the content of n-butanol extract is 11.69%, the content of total flavonoids (calculated as rutin) is 11.11%, and the ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com