Cement civil air defense door circulating water automatic maintenance device and cement civil air defense door manufacturing method

A technology of civil air defense doors and circulating water, which is applied in the direction of manufacturing tools, auxiliary molding equipment, ceramic molding machines, etc., can solve the problems of uneven water on the surface of cement civil air defense doors, affecting the effect of concrete curing, affecting the quality of concrete curing, etc., to achieve good Curing effect, not easy to evaporate, reduce the effect of improving the curing effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0056] The present application discloses a circulating water automatic maintenance device for cement air defense doors.

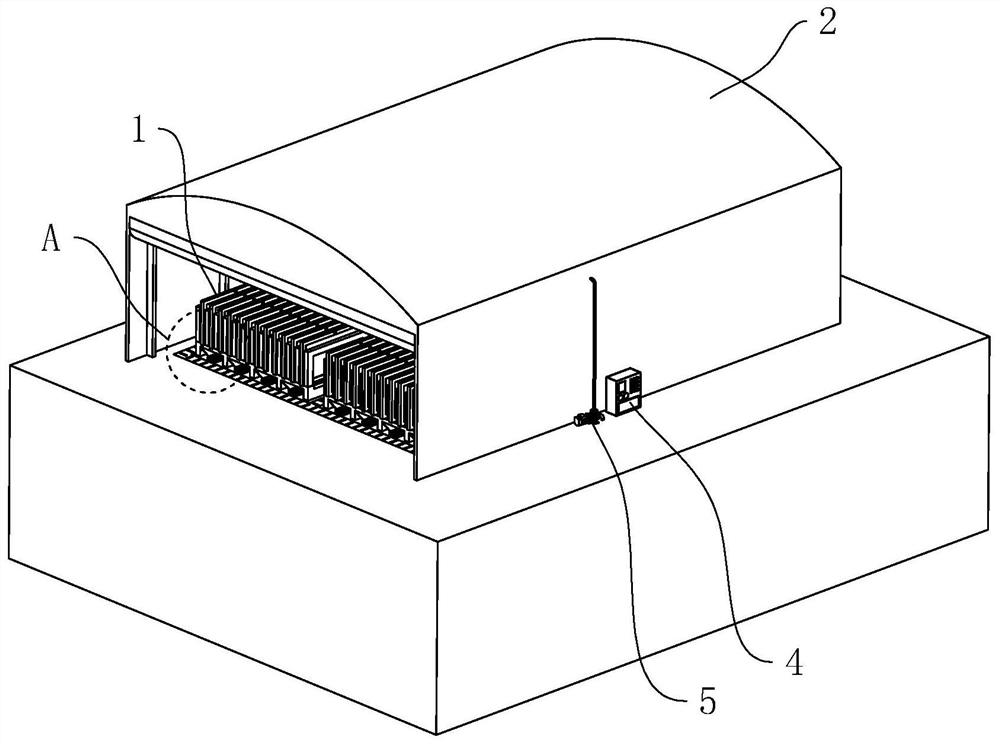

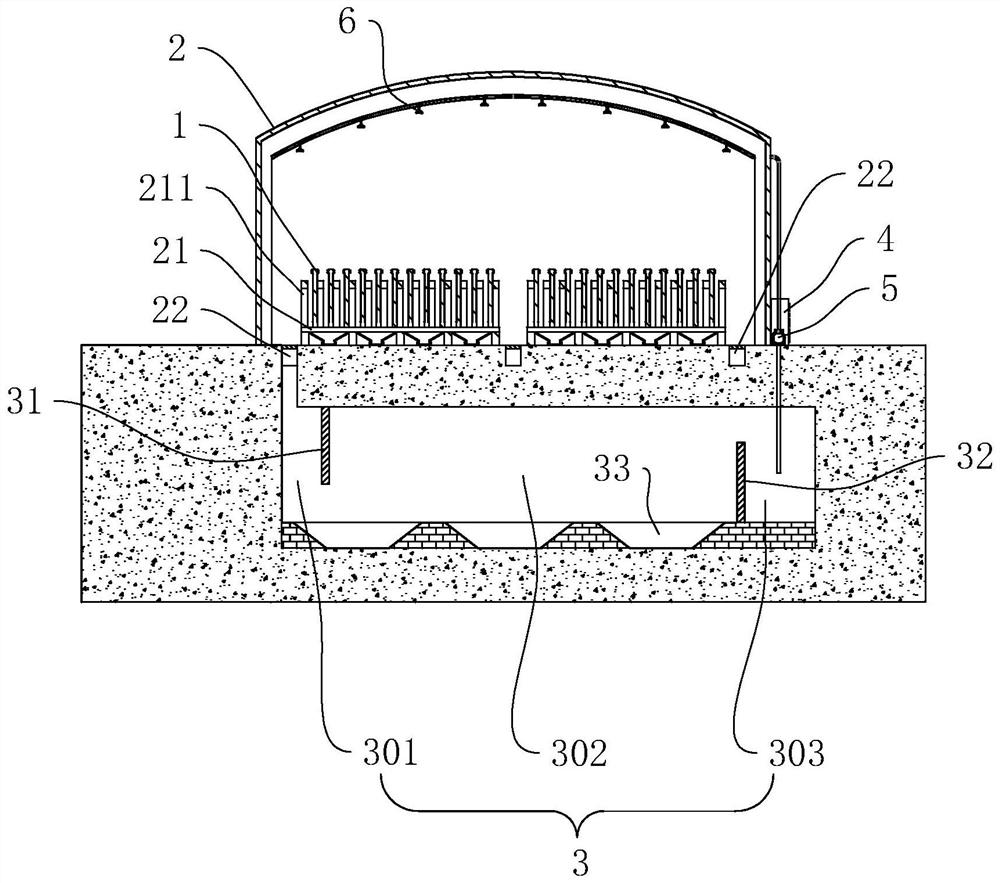

[0057] refer to Figure 1-3 , an automatic maintenance device for circulating water of cement civil air defense doors, comprising a maintenance shed 2 arranged on the ground and a water treatment pool 3 arranged underground, wherein there is maintenance water in the water treatment pool 3.

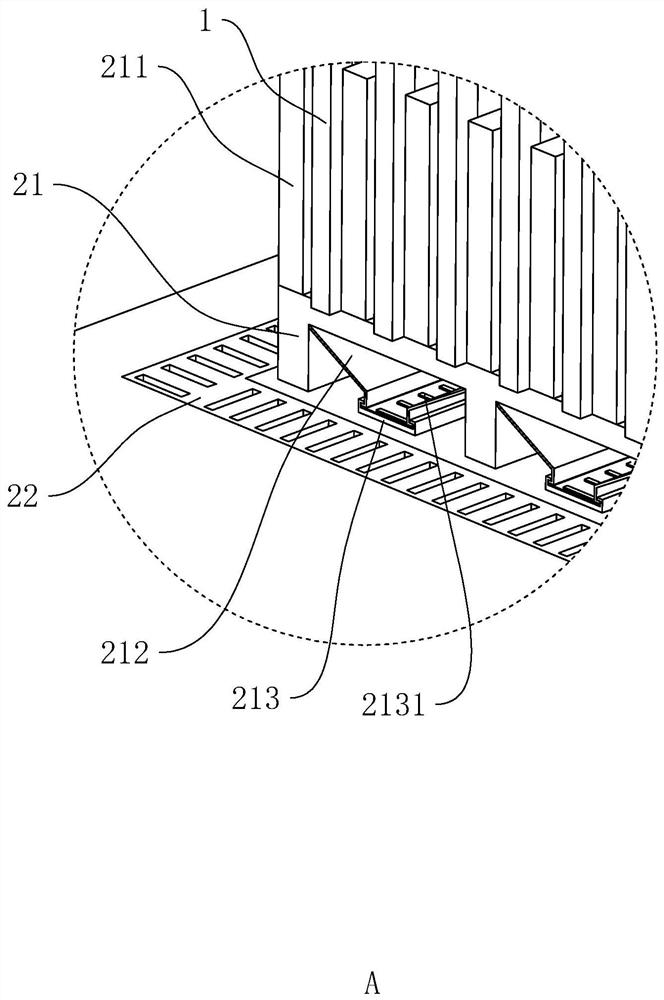

[0058] Wherein, the outer periphery of the maintenance shed 2 is covered with a tarpaulin, so that the maintenance shed 2 has better sealing performance. The ground in the maintenance shed 2 is fixed with a placement seat 21, and the placement seat 21 is specifically a hollow support. In addition, there are many groups of guardrails 211 fixed on the placement seat 21, and the plurality of groups of guardrails 211 are equidistantly spaced. A cement air defense door 1 is inserted upright, and the cement air defense door 1 can be erected on the placement seat 21 and lean ...

Embodiment 2

[0075] The difference between this embodiment and embodiment 1 is that the preparation method of curing water comprises the following steps:

[0076] 1) Mix 500kg of tap water with 32kg of polyacrylamide, 20kg of fatty alcohol polyoxyethylene ether, 27.5kg of sodium dodecylbenzenesulfonate, and 30kg of glyceryl triacetate to obtain a conservation water concentrate;

[0077] 2) Warm up the curing water concentrate to 55°C, and ultrasonically oscillate and stir at an oscillation frequency of 20HZ for 15 minutes to obtain a curing water homogeneous solution;

[0078] 3) Mix the curing water homogeneous solution with 4500 kg of tap water to obtain curing water.

Embodiment 3

[0080] The difference between this embodiment and embodiment 1 is that the preparation method of curing water comprises the following steps:

[0081] 1) 500kg of tap water is mixed with 27kg of polyacrylamide, 16kg of fatty alcohol polyoxyethylene ether, 24kg of sodium dodecylbenzenesulfonate, 25kg of triacetin, and 14kg of n-propanol to obtain curing water Concentrate;

[0082] 2) Warm up the curing water concentrate to 55°C, and ultrasonically oscillate and stir at an oscillation frequency of 20HZ for 15 minutes to obtain a curing water homogeneous solution;

[0083] 3) Mix the curing water homogeneous solution with 4500 kg of tap water to obtain curing water.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com