Hydrodeoxygenation catalyst for biological oil and fat as well as preparation and application of hydrodeoxygenation catalyst

A deoxygenation catalyst, bio-oil technology, applied in the direction of metal/metal oxide/metal hydroxide catalyst, physical/chemical process catalyst, preparation of liquid hydrocarbon mixture, etc. Application limitations, poor catalyst stability, etc., to achieve the effects of excellent hydrodeoxygenation capacity, strong hydrodecarboxylation/decarbonylation capacity, and improved stability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

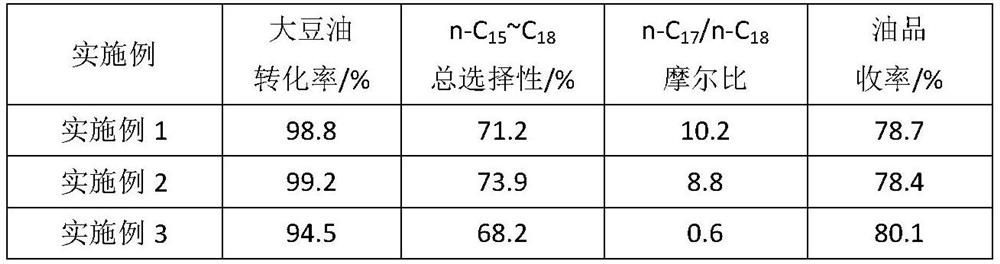

Examples

Embodiment 1

[0030] Example 1 nickel-molybdenum-lanthanum / nickel-Al 2 O 3

[0031] Weigh an appropriate amount of microsphere γ-Al 2 O 3 The carrier was evacuated at 100°C for 2h, and then lowered to room temperature, denoted as A.

[0032] Weigh 4.96gNi (NO 3 ) 2 ·6H 2O, after adding 20ml of deionized water to fully dissolve, 20g of A was immersed in the solution, dried in the shade, dried at 120°C for 12h, and calcined at 800°C for 6h in a nitrogen atmosphere to obtain B. The sample of Example 1 was subjected to XRD test. , there are diffraction peaks at 2θ=37°, 45.1° and 65.7°, belonging to NiAl 2 O 4 The characteristic peaks of the spinel structure can be seen in the microspheres of γ-Al 2 O 3 There is a nickel-aluminum spinel structure on the surface, and the surface contains Al with a nickel-aluminum spinel structure 2 O 3 Metal Ni accounts for Al in the carrier 2 O 3 The quality fraction of 5%;.

[0033] Weigh 1.56gLa (NO 3 ) 3 ·6H 2 After O was fully dissolved in ...

Embodiment 2

[0035] Example 2 nickel-molybdenum-lanthanum / nickel-Al 2 O 3

[0036] Using the vacuum-treated microsphere γ-Al in Example 1 2 O 3 Carrier, denoted as A.

[0037] Weigh 4.95g Ni (NO 3 ) 2 ·6H 2 O. After adding 20ml of deionized water to fully dissolve, 20g of A was immersed in the solution, dried in the shade, dried at 120°C for 12h, and calcined at 900°C for 6h under a nitrogen atmosphere to obtain B.

[0038] Through the XRD test on the sample of Example 2, diffraction peaks appear at 2θ=37°, 45.1° and 65.7°, which belong to NiAl 2 O 4 The characteristic peaks of the spinel structure can be seen in the microspheres of γ-Al 2 O 3 There is a nickel-aluminum spinel structure on the surface, and the surface contains Al with a nickel-aluminum spinel structure 2 O 3 Metal Ni accounts for Al in the carrier 2 O 3 The quality score of 4.99%.

[0039] Weigh 1.81gLa (NO 3 ) 3 ·6H 2 After O was fully dissolved in 20ml of deionized water, B was immersed in the solution,...

Embodiment 3

[0041] Example 3 Nickel-tungsten-lanthanum / nickel-Al 2 O 3

[0042] Weigh an appropriate amount of strip γ-Al 2 O 3 The carrier was evacuated at 100°C for 2h, and then lowered to room temperature, denoted as A.

[0043] Weigh 1.24gNi (NO 3 ) 2 ·6H 2 O. After adding 20ml of deionized water to fully dissolve, 20g of A was immersed in the solution, dried in the shade, dried at 120°C for 12h, and calcined at 800°C for 6h under nitrogen atmosphere to obtain B.

[0044] Through the XRD test on the sample of Example 3, weak diffraction peaks appear at 2θ=37°, 45.1° and 65.7°, which belong to NiAl 2 O 4 The characteristic peaks of the spinel structure can be seen in the microspheres of γ-Al 2 O 3 There is a nickel-aluminum spinel structure on the surface, and the surface contains Al with a nickel-aluminum spinel structure 2 O 3 Metal Ni accounts for Al in the carrier 2 O 3 The mass fraction of 1.25%.

[0045] Weigh 0.23gLa (NO 3 ) 3 ·6H 2 After O was fully dissolved ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com