Improved tread rubber material and preparation method thereof

A tread rubber and tread technology, which is applied in special tires, tire parts, transportation and packaging, etc., can solve the problems of reduced and increased tire performance and service life, and achieve the effect of improving interaction.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

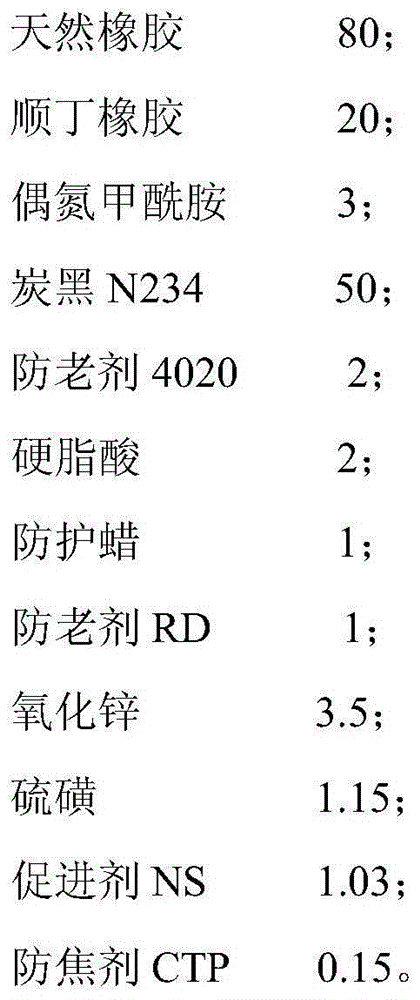

Embodiment 1

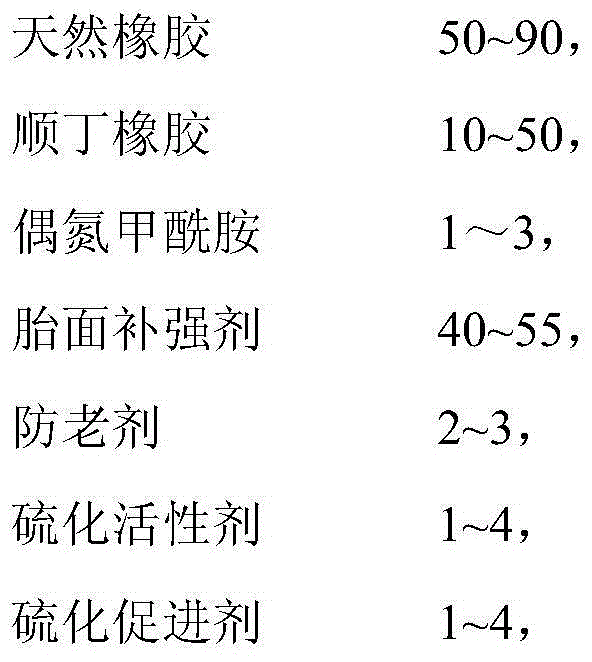

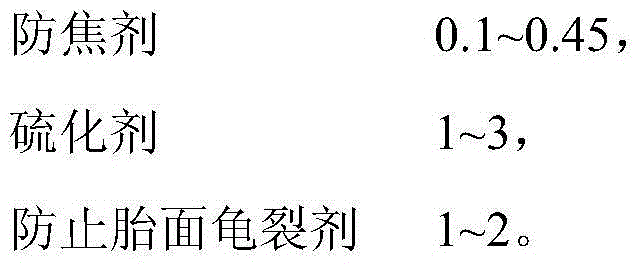

[0022] Embodiment 1, described tread rubber, the rubber material component that carries out proportioning by mass ratio is:

[0023]

[0024] For above formula content, the specific technological process of producing described tread rubber is as follows:

[0025] (1) One stage of mixing

[0026] Add natural rubber (NR), butadiene rubber (BR), carbon black and azodicarbonamide into the internal mixer and knead for 2 minutes; raise the top bolt for cleaning. Lower the top bolt and continue mixing. When the temperature is 160°C, keep mixing for 4.5 minutes, then remove the glue, unload the sheet, cool, collect the sheet, and park for at least 10 hours to obtain a section of mixed rubber.

[0027] (2) Two-stage mixing

[0028] Blend a section of rubber compound, stearic acid (SA), zinc oxide (ZnO), anti-aging agent RD, 50% anti-aging agent 4020, and protective wax for 1.5 minutes, then raise the top bolt for cleaning. Lower the top bolt and continue mixing until the internal...

Embodiment 2

[0059] For the tread rubber, the weight ratio of natural rubber and butadiene rubber in the formula is adjusted to 65:35, and the distribution ratio of all other components is shown in Table 3. The final rubber mixing process, vulcanization process and other conditions are the same as in Example 1. The vulcanized rubber samples were made into standard specimens, and various mechanical tests, wear resistance tests, and compression heat generation tests were carried out. The results are shown in Table 4.

[0060] The specific mixing process of rubber segment is as follows:

[0061] a mixing

[0062] Add NR, BR, carbon black and azodicarbonamide to the internal mixer and knead for 2 minutes; raise the top bolt for cleaning. Lower the top bolt and continue mixing. When the temperature is 154°C, keep mixing for 4.5 minutes, then remove the glue, unload the sheet, cool, collect the sheet, and park for at least 10 hours to obtain a section of mixed rubber.

[0063] two stage mixin...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com