Method for brazing foamed aluminum plate and aluminum plate by removing interfacial oxide films through bubble wall friction

A foamed aluminum plate and oxide film technology, which is used in welding equipment, welding/welding/cutting items, manufacturing tools, etc., can solve the problems of low joint strength of foamed aluminum and aluminum plate, difficult to remove oxide film, and non-wetting of solder. Achieve improved wetting and spreading, short welding cycle times and low cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach 1

[0014] Specific implementation mode one: combine Figure 1 to Figure 5 Describe this implementation mode, this implementation mode is realized through the following steps:

[0015] Step 1, cleaning and drying the foamed aluminum plate 2 and the dense aluminum plate 3;

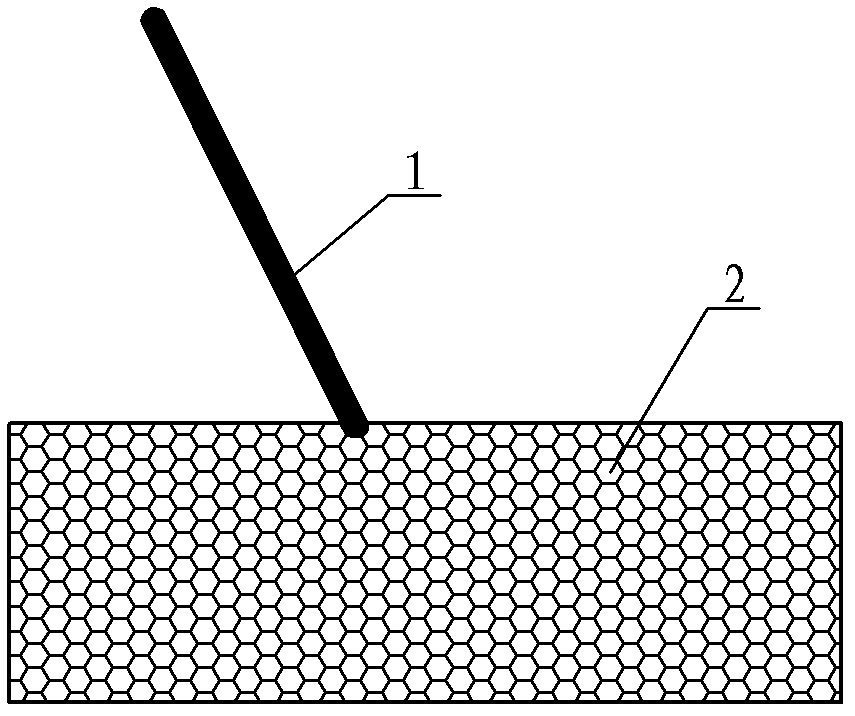

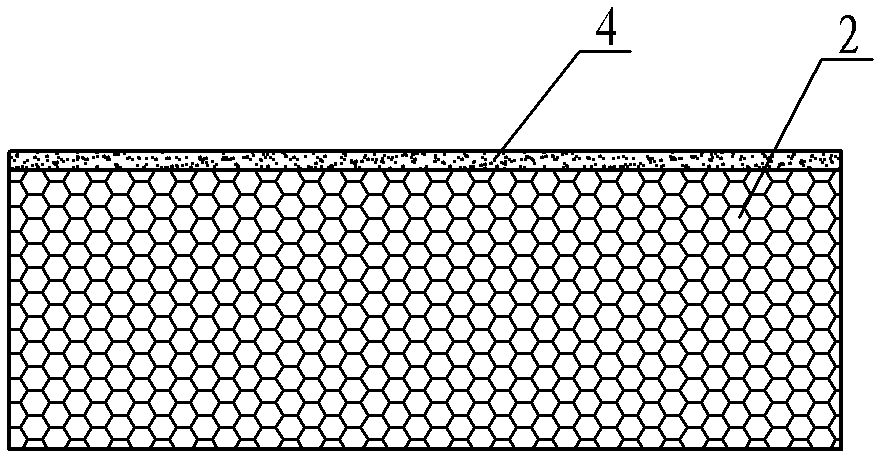

[0016] Step 2: Heat the aluminum foam board 2 as a whole to above the melting point of the brazing material, that is, between 350°C and 460°C, and use the rod-shaped Zn-Al-Cu brazing filler metal to reciprocate on the surface to be welded of the aluminum foam board 2, see figure 1 , so that the melted brazing material is evenly coated on the surface of the foamed aluminum plate 2 to be welded, see figure 2 , naturally cooled to room temperature (20 ° C ~ 25 ° C);

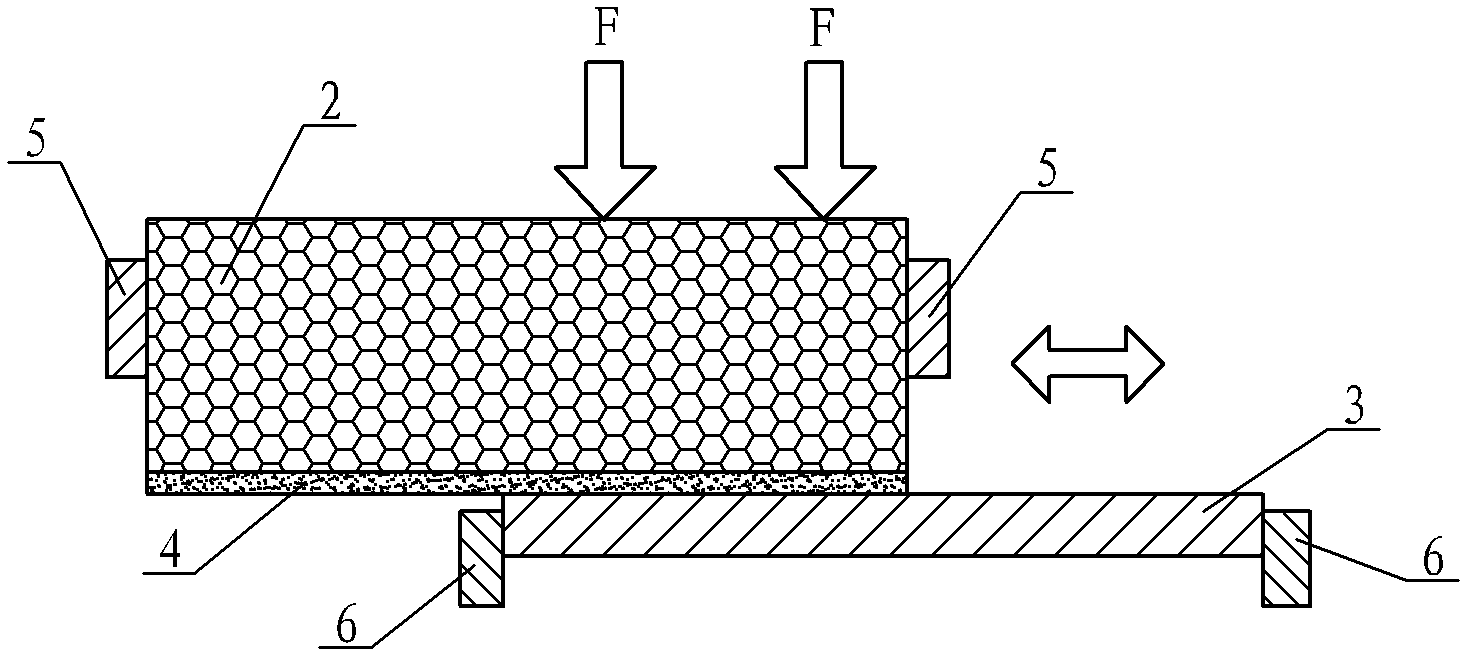

[0017] Step 3: Fix the weldment of the dense aluminum plate 3 on the fixing jig 6, fix the weldment of the foamed aluminum plate 2 coated with brazing material on the sliding jig 5, and coat the end surface of the foamed aluminum plate 2 with braz...

specific Embodiment approach 2

[0020] Embodiment 2: The heating temperature in step 1 of this embodiment is 400°C-430°C. Other steps are the same as in the first embodiment.

specific Embodiment approach 3

[0021] Embodiment 3: In step 2 of this embodiment, the way of heating the aluminum foam board 2 as a whole adopts a propane flame or an oxyacetylene flame. Other steps are the same as in the first embodiment.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com