Preparation method of anti-corrosive polyurea elastomer coating

A polyurea elastomer and coating technology, which is applied in the direction of anti-corrosion coatings and coatings, can solve the problems of low anti-corrosion performance and difficulty in meeting the requirements of harsh environments

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0031] The present invention also provides a kind of preparation method of anticorrosion polyurea elastomer coating, comprises the following steps:

[0032] (1) Carry out vacuum dehydration treatment on polyether diol, react the dehydrated polyether diol, diisocyanate and diluent in an inert gas atmosphere at 40-95°C for 2-4 hours, cool and discharge, Obtain component A;

[0033] (2) Dehydrate the amino-terminated polyether and the amine chain extender in the reaction kettle under reduced pressure, then add composite reinforcing materials and catalysts, stir at 40-60°C for 1-2 hours, ultrasonicate for 5-15 minutes, and cool Discharging to obtain component B;

[0034] Wherein, the composite reinforcing material includes epoxy resin, polyamide resin, BYK additives and silicon dioxide.

[0035] According to the present invention, by ultrasonically treating component B in the present invention, the uniformity and reactivity between the components can be improved, the mutual reac...

Embodiment 1

[0041] (1) Pour 45 parts by weight of polyoxypropylene glycol into the reactor for vacuum dehydration. The temperature of vacuum dehydration is 120°C, the pressure is -0.1MPa, and the extraction time is 2h, then the temperature is lowered to 65°C, and the Add 50 parts by weight of MDI-5005 and 5 parts by weight of ethyl carbonate, then raise the temperature to 60°C for 3 hours, cool and discharge to obtain component A;

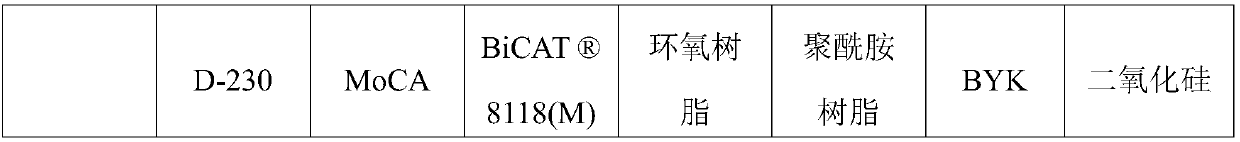

[0042] (2) 44.5 parts by weight of D-230 and 28.4 parts by weight of MoCA were respectively dehydrated under reduced pressure in a reactor. 8118(M), 11.61 parts by weight of epoxy resin, 7.29 parts by weight of polyamide resin, 7.02 parts by weight of BYK additives and 1.08 parts by weight of silica, stirred at 50 ° C for 1.5 h, and ultrasonicated at 400 W for 10 min, Cooling and discharging to obtain component B.

[0043] The content of each component in component A in this embodiment is shown in Table 1, and the content of each component in component B is ...

Embodiment 2

[0050] (1) Pour 55 parts by weight of polytetrahydrofuran glycol into the reactor for vacuum dehydration. The temperature of vacuum dehydration is 120°C, the pressure is -0.1MPa, and the extraction time is 2h, then the temperature is lowered to 65°C, and the Add 37 parts of PAPI and 8 parts of di-n-octyl phthalate, then raise the temperature to 75°C for 2.5 hours, cool and discharge to obtain component A;

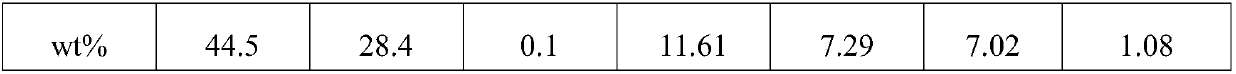

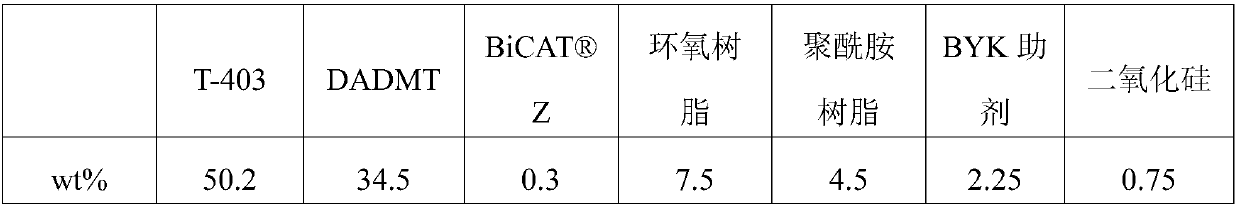

[0051] (2) 50.2 parts by weight of T-403 and 34.5 parts by weight of DADMT were respectively dehydrated under reduced pressure in a reactor. Z, 7.5 parts by weight of epoxy resin, 4.5 parts by weight of polyamide resin, 2.25 parts by weight of BYK additives and 0.75 parts by weight of silica, stirred at 50°C for 1.5h, ultrasonicated at 400W for 10min, cooled and discharged , to obtain component B.

[0052] The content of each component in component A in this embodiment is shown in Table 3, and the content of each component in component B is shown in Table 4.

[0053] Tab...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com