A highly active electrocatalyst for polymer electrolyte membrane fuel cell and a preparation method thereof

An electrolyte membrane, fuel cell technology, applied in fuel cells, battery electrodes, electrochemical generators, etc., can solve problems such as single-atom catalysts that have not been seen, and achieve the effect of improving interaction and stability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

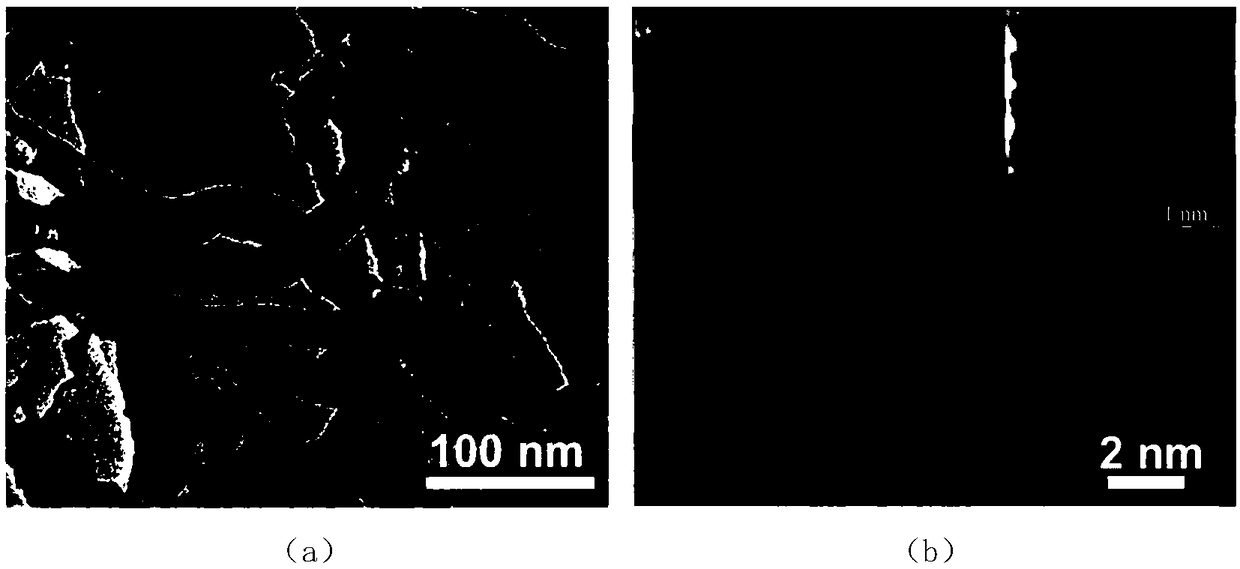

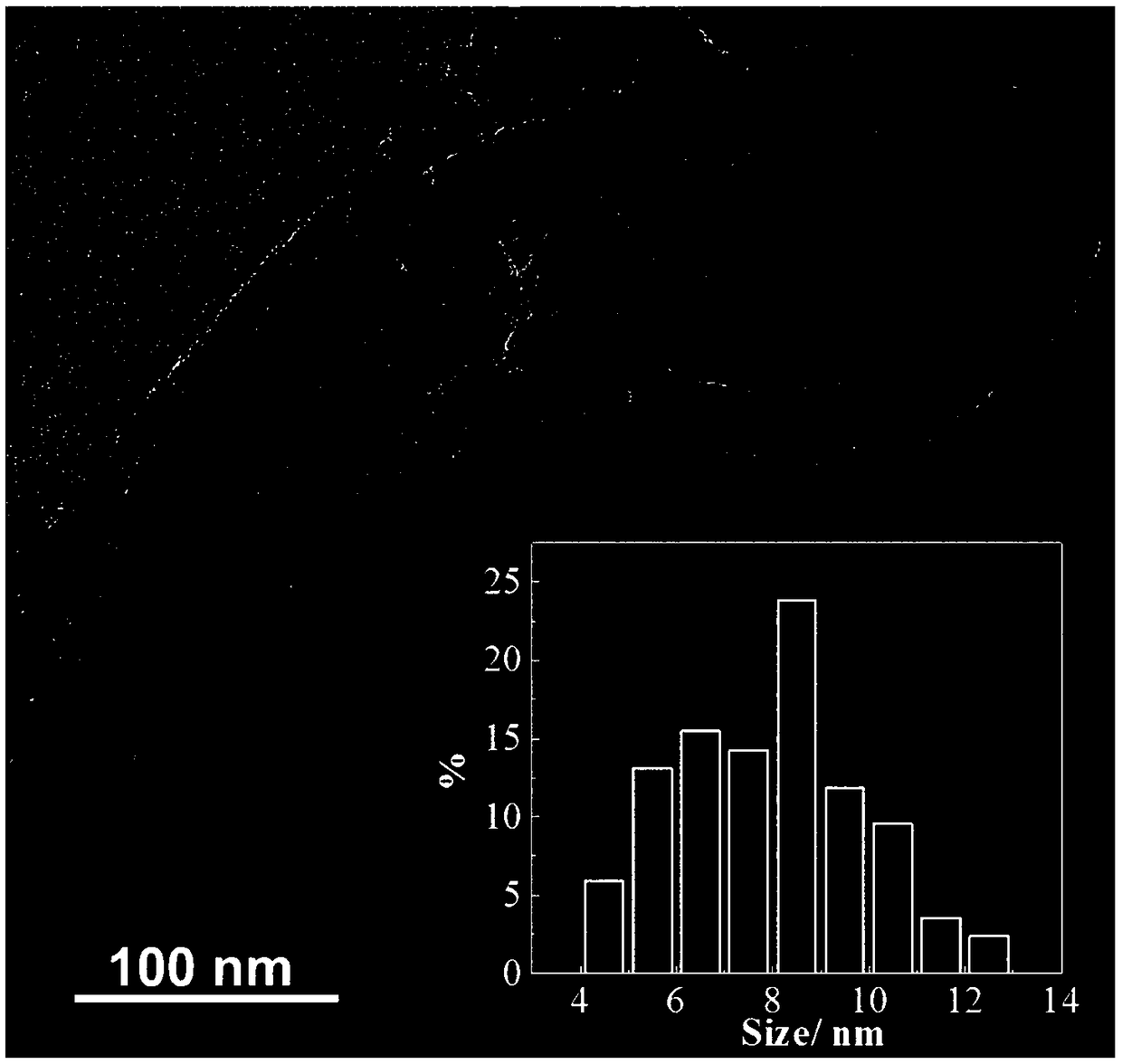

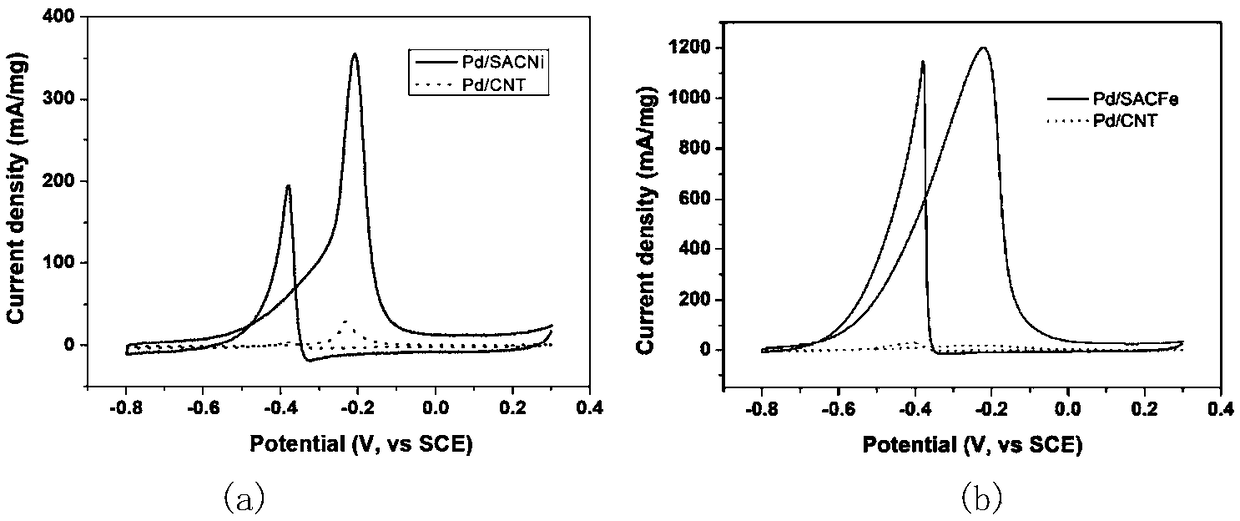

[0029] Weigh 10g of dicyandiamide and 0.1g of nickel acetylacetonate respectively, mix them uniformly mechanically, and then grind them repeatedly for about 6 hours to make them mix as uniformly as possible, place them in a tube furnace, use argon as an inert protective gas, and 1°C / min heating rate, raised to 300°C, heat treatment for 3 hours, then continued to heat up to 600°C, continued heat treatment for 3 hours, then raised the temperature to 800°C again, heat treated for 1 hour, cooled to room temperature under an inert atmosphere, and obtained nickel Monoatomically dispersed carbon nanotube supports. Weigh 0.1 g of the above-mentioned carbon nanotube carrier and place it in a round bottom flask, add 150 ml of ethylene glycol, and ultrasonically disperse for 30 minutes to disperse the carbon nanotube carrier evenly, and then add PdCl 2 The salt solution was continuously stirred for 3 hours, then ascorbic acid was added as an auxiliary reducing agent, and the stirring was...

Embodiment 2

[0032] Weigh 10g of dicyandiamide and 0.1g of iron acetylacetonate respectively, mechanically mix them uniformly, and then grind them repeatedly for about 6 hours to make the two as uniform as possible, place them in a tube furnace, use argon as an inert protective gas, and 1°C / min heating rate, raised to 300°C, heat treatment for 3 hours, then continued to heat up to 600°C, continued heat treatment for 3 hours, then raised the temperature to 900°C again, heat treated for 1 hour, and cooled to room temperature under an inert atmosphere to obtain iron Monoatomically dispersed carbon nanotube supports. Weigh 0.1 g of the above-mentioned carbon nanotube carrier and place it in a round bottom flask, add 150 ml of ethylene glycol, and ultrasonically disperse for 30 minutes to disperse the carbon nanotube carrier evenly, and then add PdCl 2 The salt solution was continuously stirred for 3 hours, then ascorbic acid was added as an auxiliary reducing agent, and the stirring was contin...

Embodiment 3

[0035] Weigh 10g of dicyandiamide and 0.1g of copper acetylacetonate respectively, mix them uniformly mechanically, and then grind them repeatedly for about 6 hours to make the two as uniform as possible, place them in a tube furnace, use argon as an inert protective gas, and 1°C / min heating rate, raised to 250°C, heat treatment for 3 hours, then continued to heat up to 600°C, continued heat treatment for 3 hours, then raised the temperature to 750°C again, heat treated for 1 hour, cooled to room temperature under an inert atmosphere, and obtained copper Monoatomically dispersed carbon nanotube supports. Weigh 0.1 g of the above-mentioned carbon nanotube carrier and place it in a round-bottomed flask, add 150 ml of ethylene glycol, and ultrasonically disperse for 30 minutes to disperse the carbon nanotube carrier evenly, and then add the PdCl required to prepare 30 wt% Pd nanoparticles. 2 The salt solution was continuously stirred for 3 hours, then ascorbic acid was added as a...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com