Acetylene process vinyl acetate catalyst

A vinyl acetate and catalyst technology, which is applied in the field of acetylene vapor phase vinyl acetate catalyst, can solve the problems of low benzene content of by-products and high content of by-product benzene, and achieve the effects of reducing benzene content, improving selectivity, and good technical effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

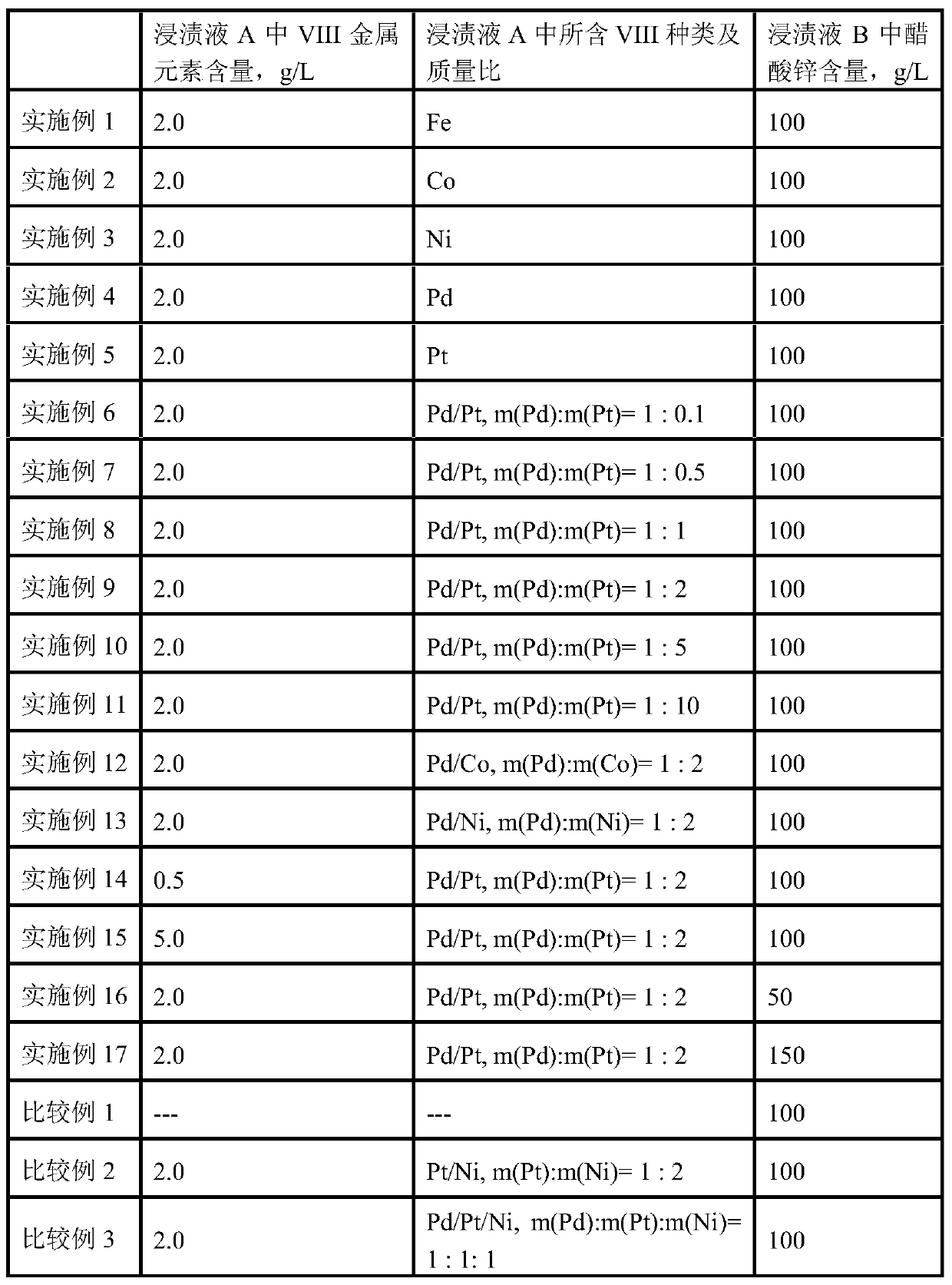

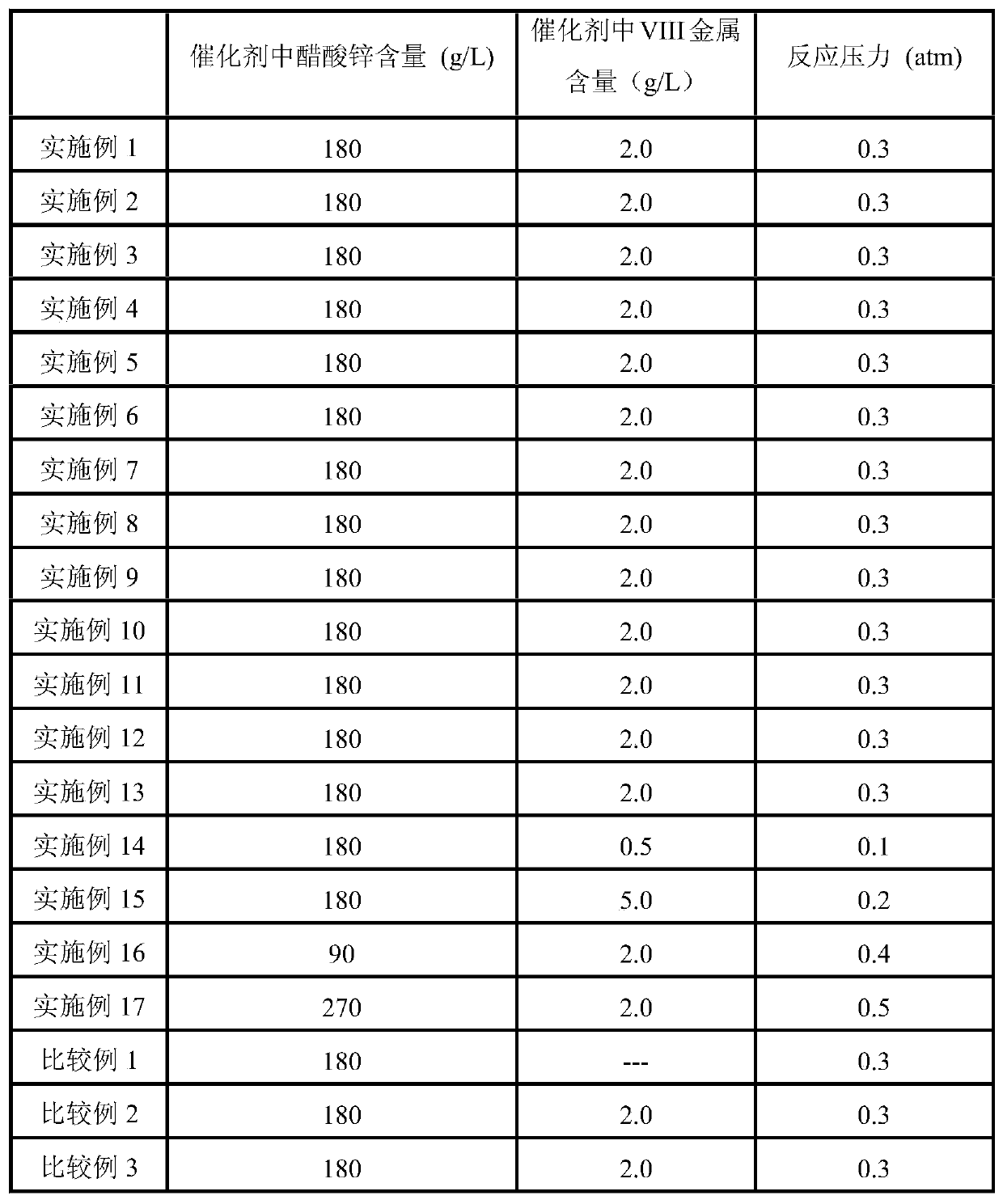

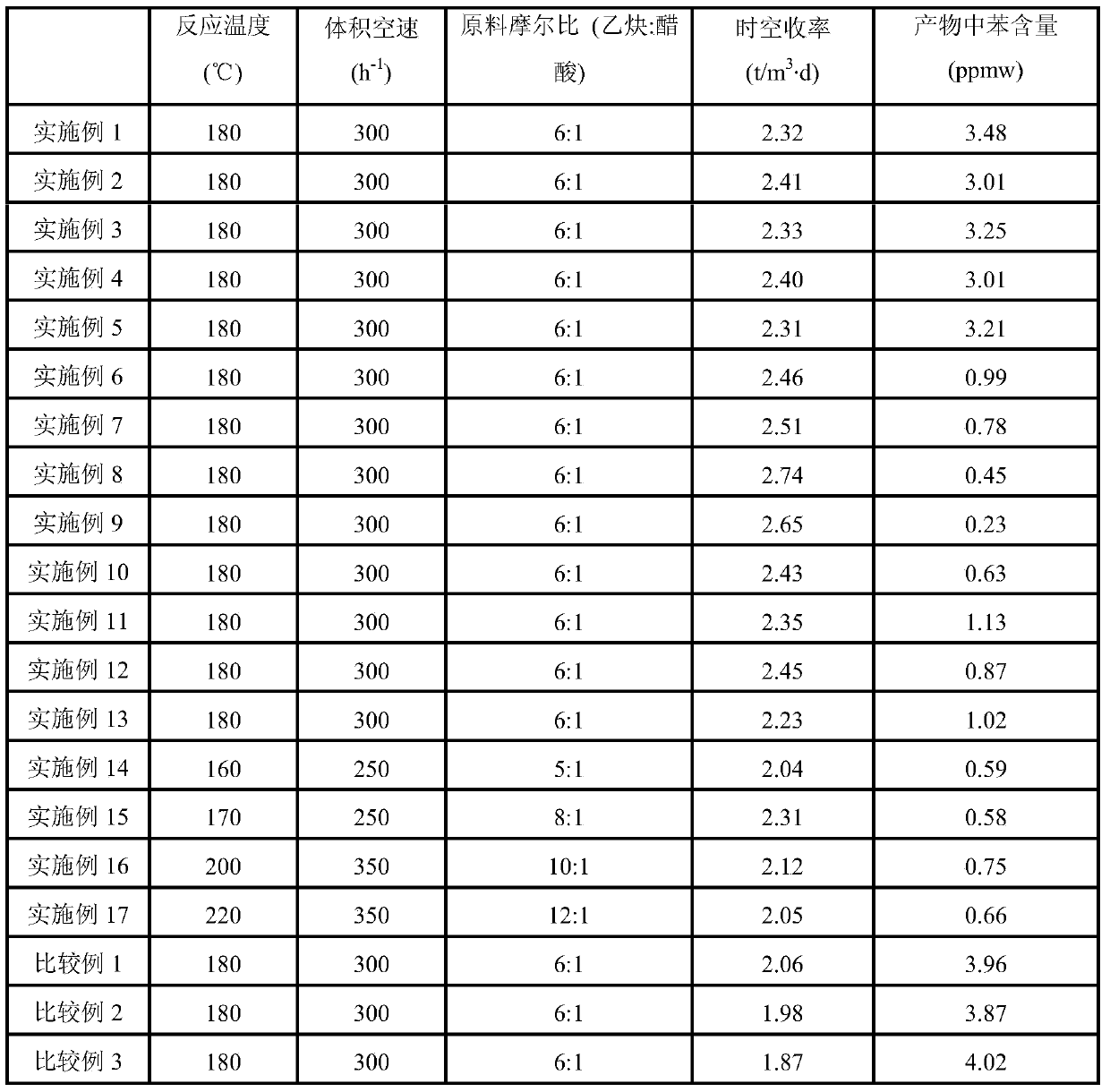

Examples

Embodiment 1

[0029] (1) Catalyst preparation

[0030] (a) Impregnation: take Fe(NO 3 ) 3 100ml of aqueous solution is impregnation solution A (Fe 3+ Concentration: 2.0g / L), impregnate 100ml of coal-based columnar carbon with a diameter of 2.4mm and a length of 2cm at a room temperature of 25°C (BET specific surface 1200cm 2 / g, the total adsorption pore volume is 0.7cm 3 / g) 3h;

[0031] (b) drying: after drying in a vacuum oven at 90° C. for 4 hours, the carrier precursor is obtained;

[0032] (c) reduction: in H 2 / N 2 Mixed gas (H 2 Molar concentration is 10%) after reduction at 200°C for 1h, in N 2 Cool to room temperature in the atmosphere to obtain a modified activated carbon carrier;

[0033] (d) Preparation of immersion solution: Weigh 18.0g of zinc acetate (molecular formula: Zn(CH 3 COO) 2 ) solid was dissolved in pure water at 60°C to prepare 180ml of impregnating liquid, and acetic acid was used to adjust the pH value of the impregnating liquid to 4.85 to obtain impr...

Embodiment 2

[0048] (1) Catalyst preparation

[0049] (a) Impregnation: take CoCl-containing 2 100ml of aqueous solution is impregnation solution A (Co 2+ Concentration: 2.0g / L), impregnate 100ml of coal-based columnar carbon with a diameter of 2.4mm and a length of 2cm at a room temperature of 25°C (BET specific surface 1200cm 2 / g, the total adsorption pore volume is 0.7cm 3 / g) 3h;

[0050] (b) drying: after drying in a vacuum oven at 90° C. for 4 hours, the carrier precursor is obtained;

[0051] (c) reduction: in H 2 / N 2 Mixed gas (H 2 Molar concentration is 10%) after reduction at 200°C for 1h, in N 2 Cool to room temperature in the atmosphere to obtain a modified activated carbon carrier;

[0052] (d) Preparation of immersion solution: Weigh 18.0g of zinc acetate (molecular formula: Zn(CH 3 COO) 2 ) solid was dissolved in pure water at 60°C to prepare 180ml of impregnating liquid, and acetic acid was used to adjust the pH value of the impregnating liquid to 4.85 to obtain...

Embodiment 3

[0059] (1) Catalyst preparation

[0060] (a) Impregnation: take Ni(NO 3 ) 2 100ml of aqueous solution is impregnation solution A (Ni 2+ Concentration: 2.0g / L), impregnate 100ml of coal-based columnar carbon with a diameter of 2.4mm and a length of 2cm at a room temperature of 25°C (BET specific surface 1200cm 2 / g, the total adsorption pore volume is 0.7cm 3 / g) 3h;

[0061] (b) drying: after drying in a vacuum oven at 90° C. for 4 hours, the carrier precursor is obtained;

[0062] (c) reduction: in H 2 / N 2 Mixed gas (H 2 Molar concentration is 10%) after reduction at 200°C for 1h, in N 2 Cool to room temperature in the atmosphere to obtain a modified activated carbon carrier;

[0063] (d) Preparation of immersion solution: Weigh 18.0g of zinc acetate (molecular formula: Zn(CH 3 COO) 2 ) solid was dissolved in pure water at 60°C to prepare 180ml of impregnating liquid, and acetic acid was used to adjust the pH value of the impregnating liquid to 4.85 to obtain impr...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Diameter | aaaaa | aaaaa |

| Adsorption total pore volume | aaaaa | aaaaa |

| Specific surface | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com