Patents

Literature

82 results about "Vinyl acetate synthesis" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

VAM PRODUCTION PROCESS. The first available process for the synthesis of vinyl acetate was the acetoxilation of acetylene in gaseous form over a zinc acetate catalyst supported on carbon. This process consisted in the reaction of acetylene with acetic anhydride in a catalyzed medium and high temperature to form dietilene diacetate.

Acetylene method vinyl acetate catalyst and preparation method thereof

InactiveCN104437627AUniform load carrierStable load carrierOrganic compound preparationOrganic-compounds/hydrides/coordination-complexes catalystsActivated carbonPtru catalyst

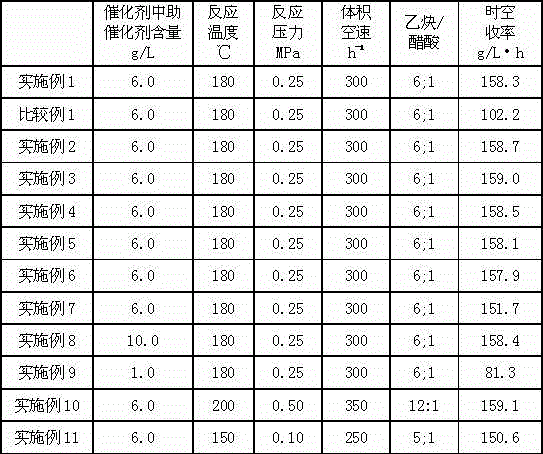

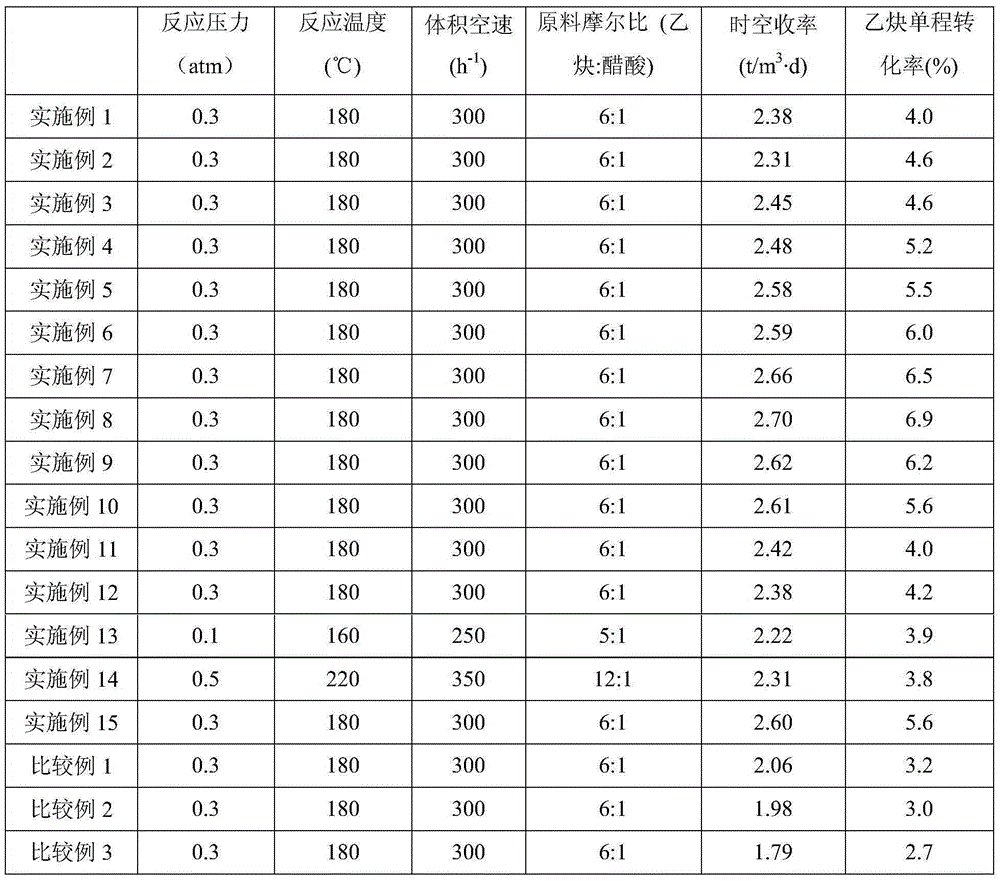

The invention relates to a vinyl acetate catalyst, a preparation method and a vinyl acetate synthesis method which are mainly used for solving the problem of low catalyst activity in the prior art. In order to better solve the problem, the technical scheme adopted by the invention is as follows: the vinyl acetate catalyst provided by the invention comprises a carrier, 50-200 g / L zinc acetate and 0-10 g / L potassium acetate; the preparation method comprises the following steps: (a) performing microwave treating on activated carbon under a non-oxidizing atmosphere relative to the activated carbon to obtain the carrier; (b) loading the necessary dosage of zinc acetate and a cocatalyst by an impregnation method; (c) drying to obtain the catalyst. The vinyl acetate catalyst can be used in the industrial production of acetylene method vinyl acetate synthesis.

Owner:CHINA PETROLEUM & CHEM CORP +1

Catalyst for vinyl acetate synthesis by acetylene method and preparation method thereof

ActiveCN104549497AHigh selectivityReduce benzene contentOrganic compound preparationOrganic-compounds/hydrides/coordination-complexes catalystsBenzeneActivated carbon

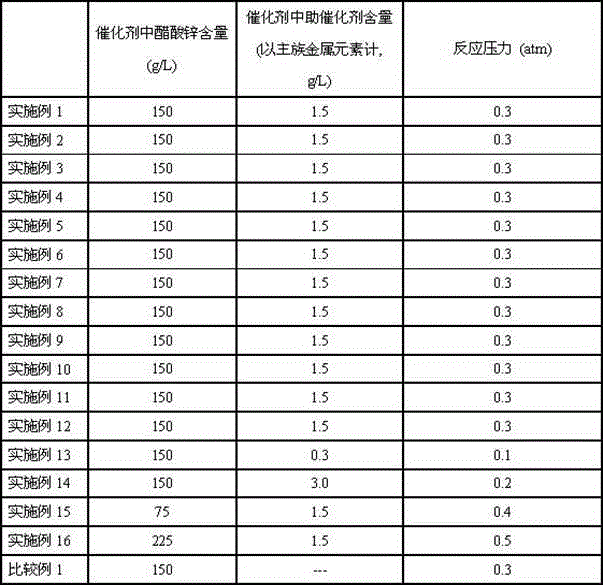

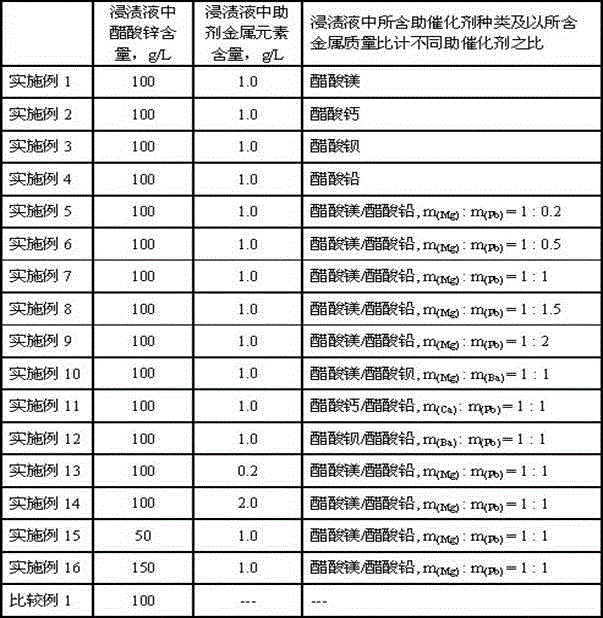

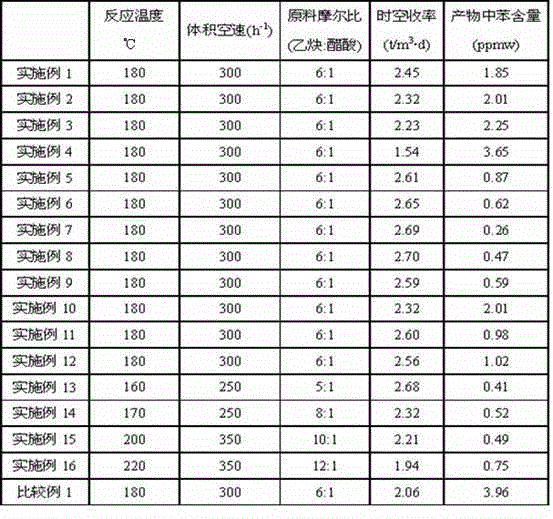

The invention relates to a catalyst for vinyl acetate synthesis by an acetylene method and a preparation method thereof as well as a synthesis method of vinyl acetate, and aims at mainly solving the problem in the prior art that the content of byproduct benzene in a vinyl acetate product is high. The problem is well solved by adopting the technical scheme that the catalyst comprises a carrier, an active component and a cocatalyst, wherein the carrier is active carbon, the active component is zinc acetate, and the content of zinc acetate in the catalyst is 80g / L-240g / L. The catalyst is characterized in that the cocatalyst of the catalyst is acetate of main group metal elements in the periodic table of elements, wherein the main group metal elements are selected from at least one of IIA group metal elements or IVA group metal elements. The catalyst can be used for industrial production of the synthesis of vinyl acetate by the acetylene method.

Owner:CHINA PETROLEUM & CHEM CORP +1

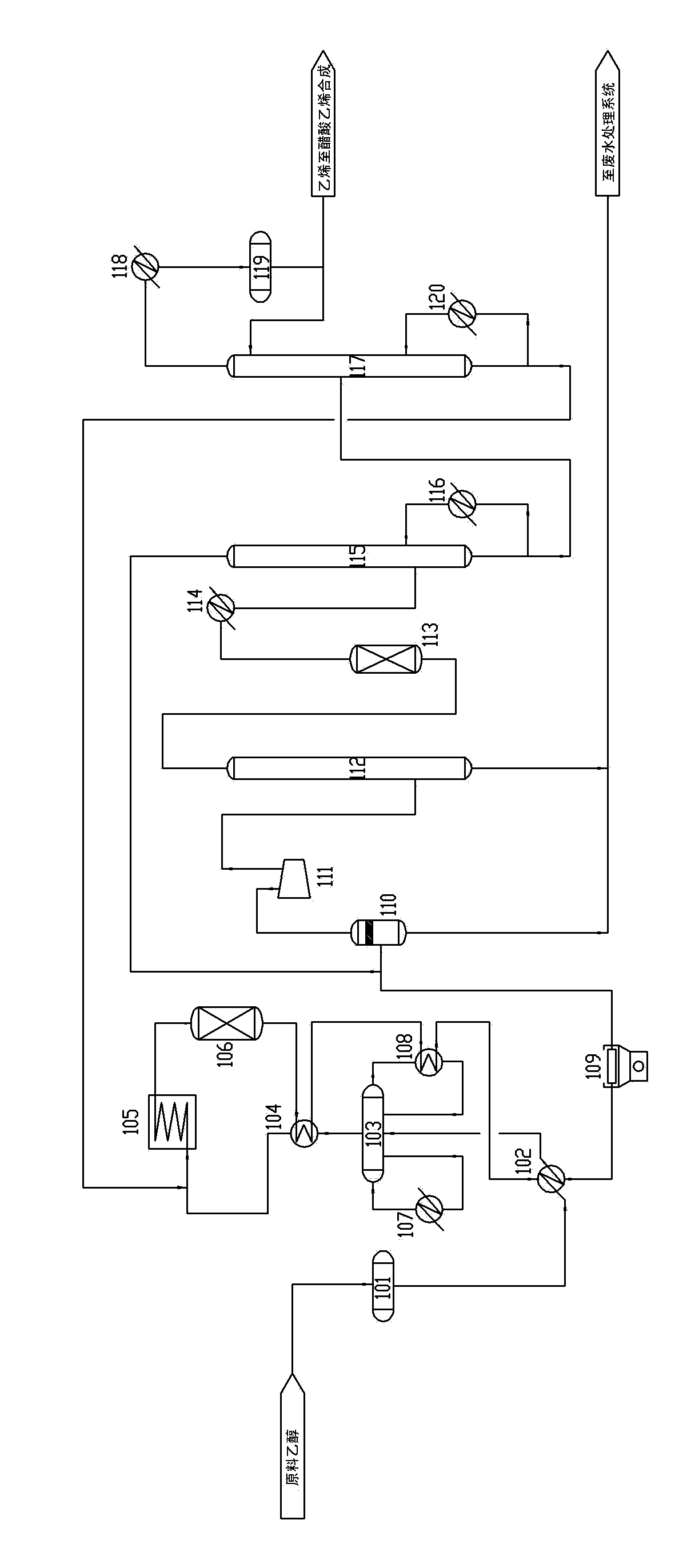

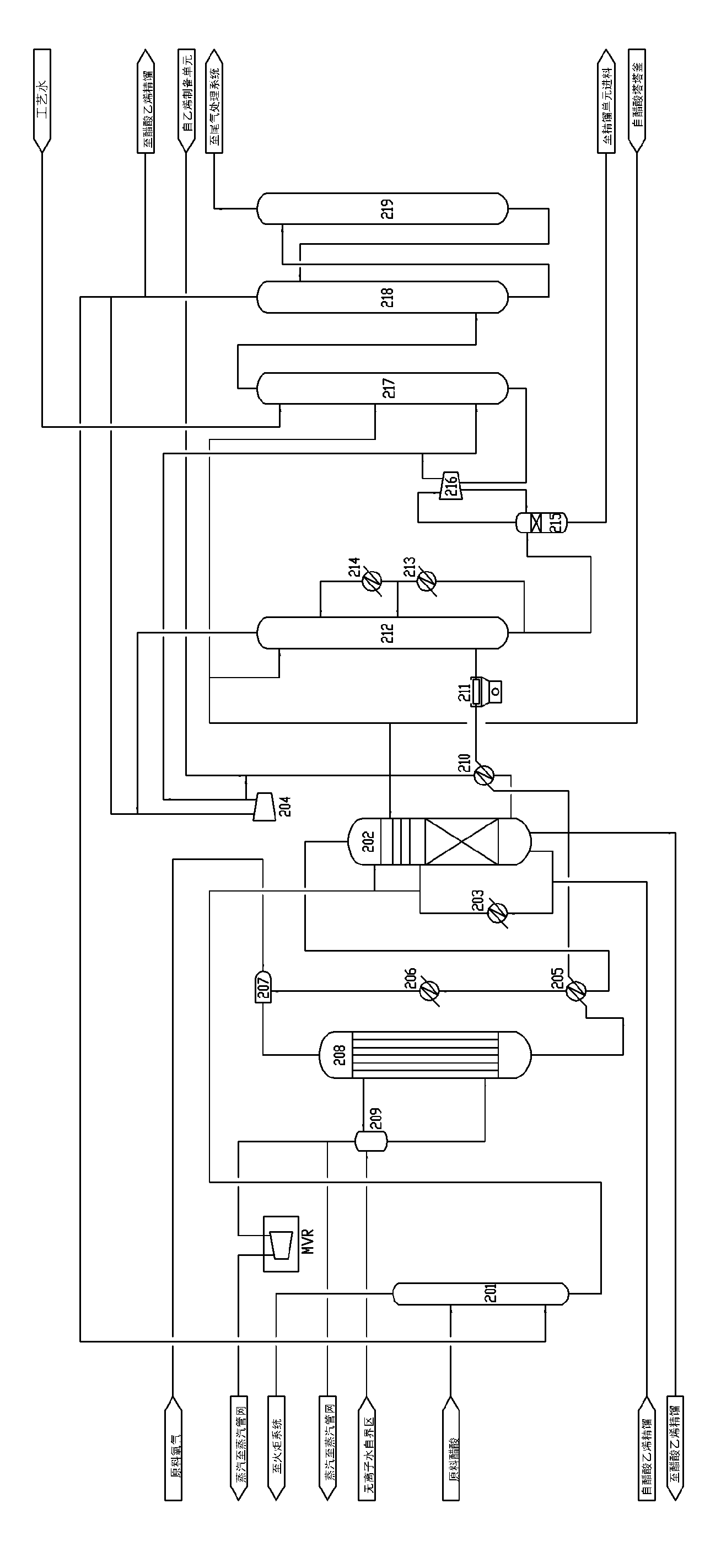

Vinyl acetate production method

ActiveCN102936198AOrganic compound preparationCarboxylic acid esters separation/purificationPlate heat exchangerShell and tube heat exchanger

The present invention relates to a vinyl acetate production method. The present invention provides a method for producing vinyl acetate through ethylene vapor-phase oxidation, wherein the method comprises an optionally ethylene preparation process, a vinyl acetate synthesis process and a vinyl acetate refinement process, and at least one process of the ethylene preparation process, the vinyl acetate synthesis process and the vinyl acetate refinement process adopts at least one selected from a steam mechanical recompression technology, an air cooler, a plate heat exchanger and a double shell side shell and tube heat exchanger.

Owner:TIANJIN UNIV

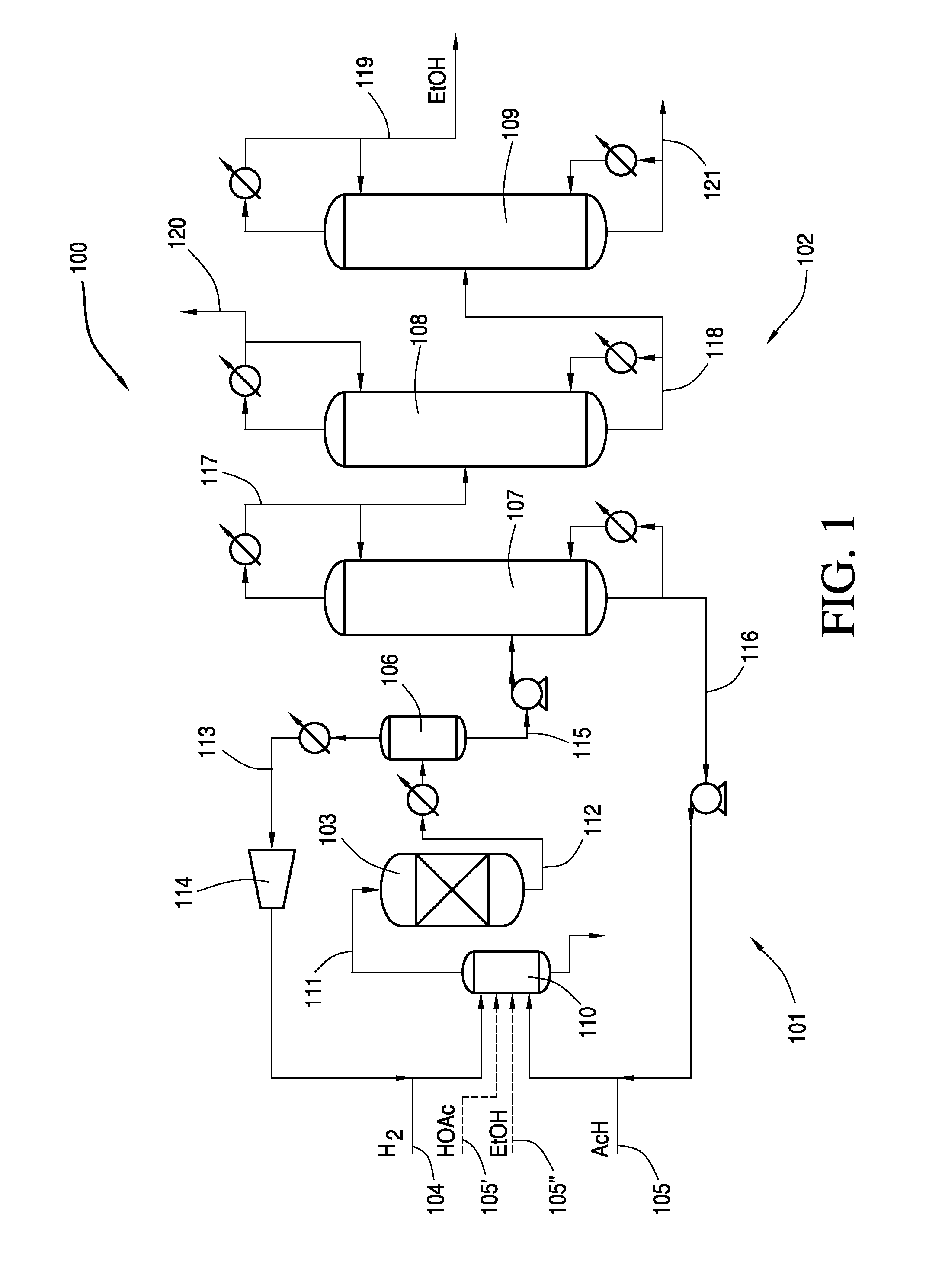

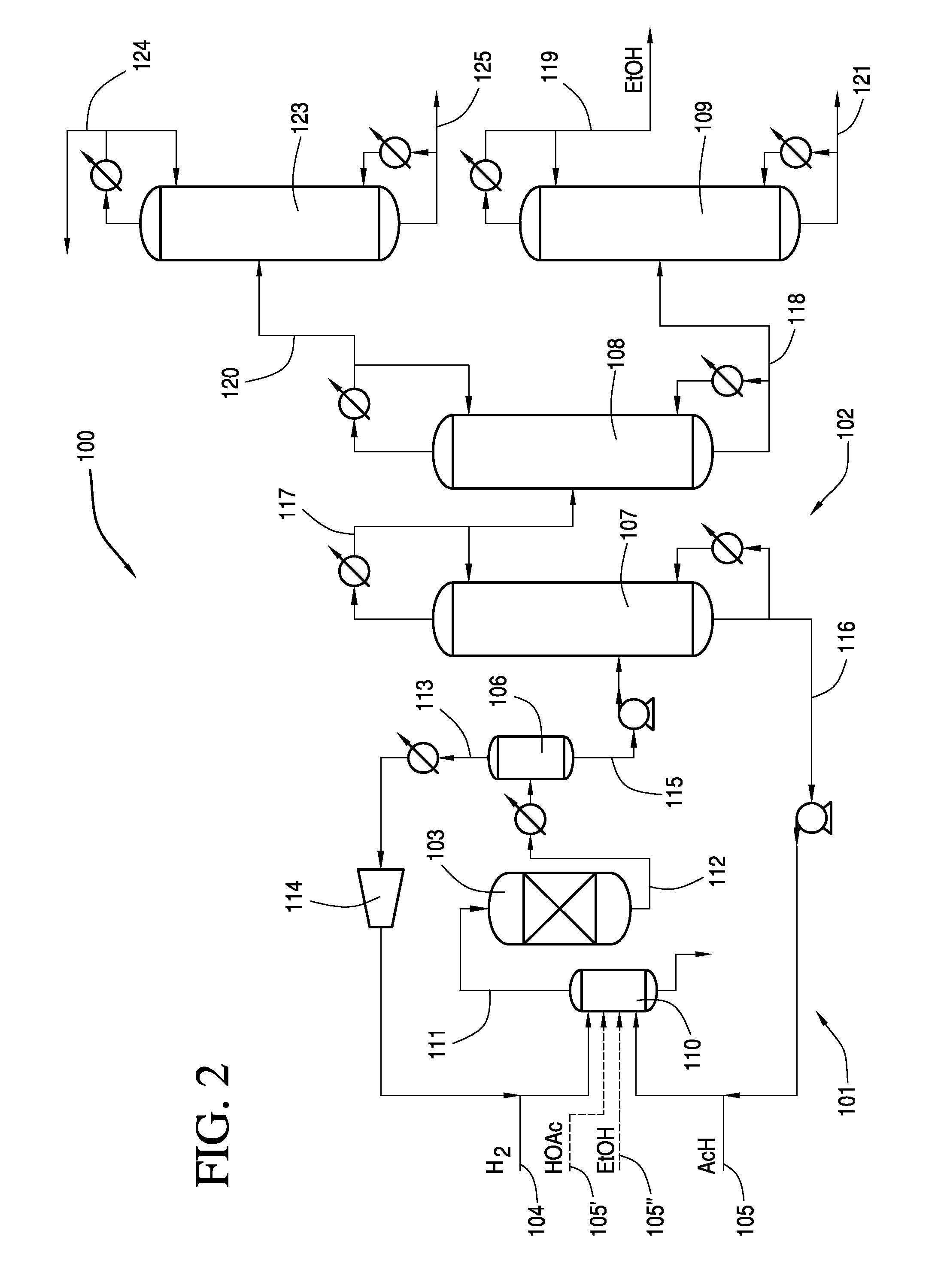

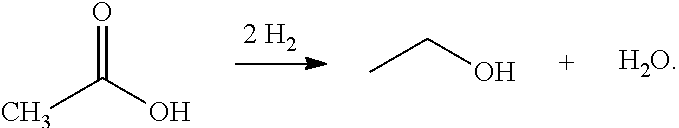

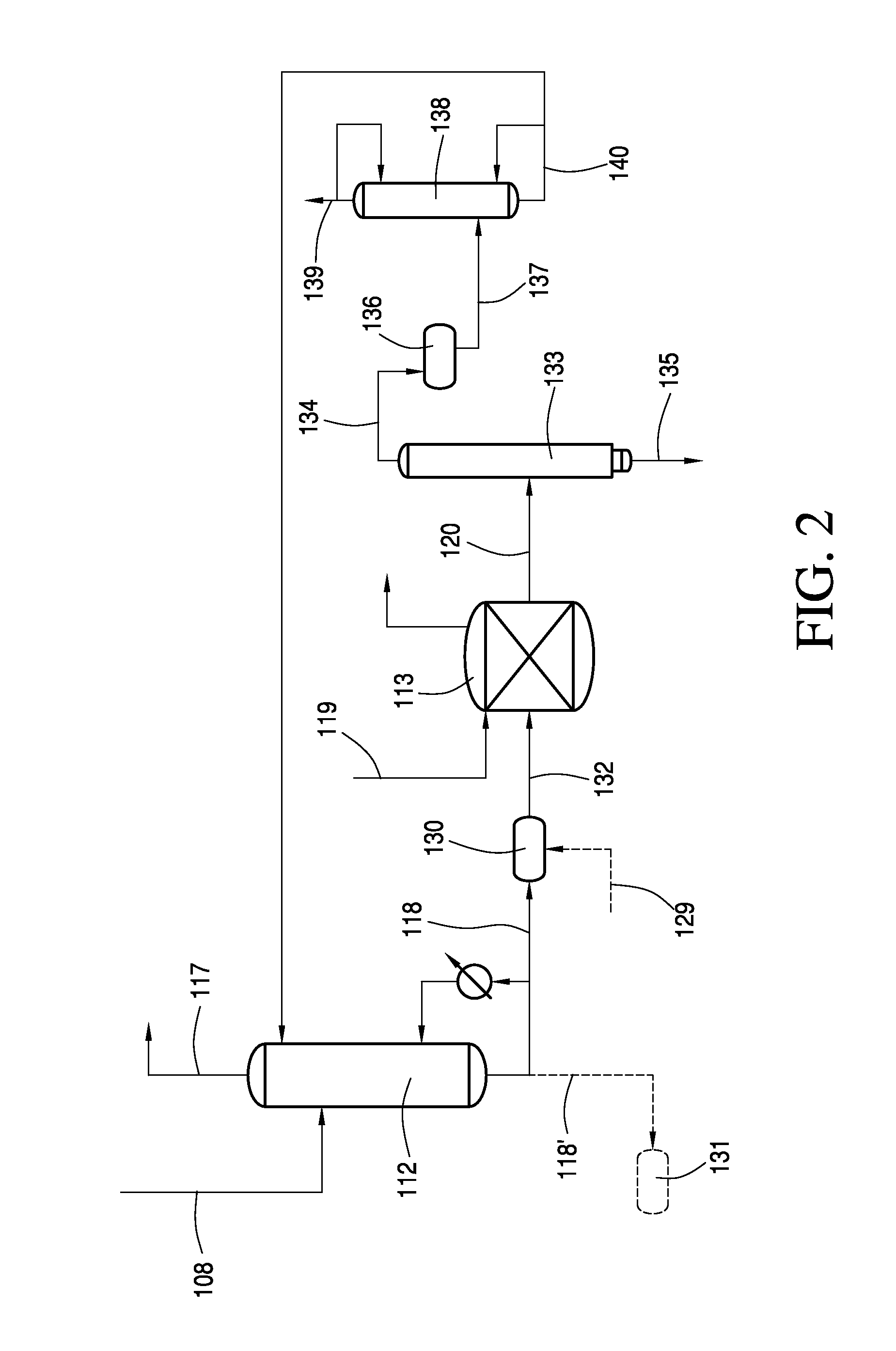

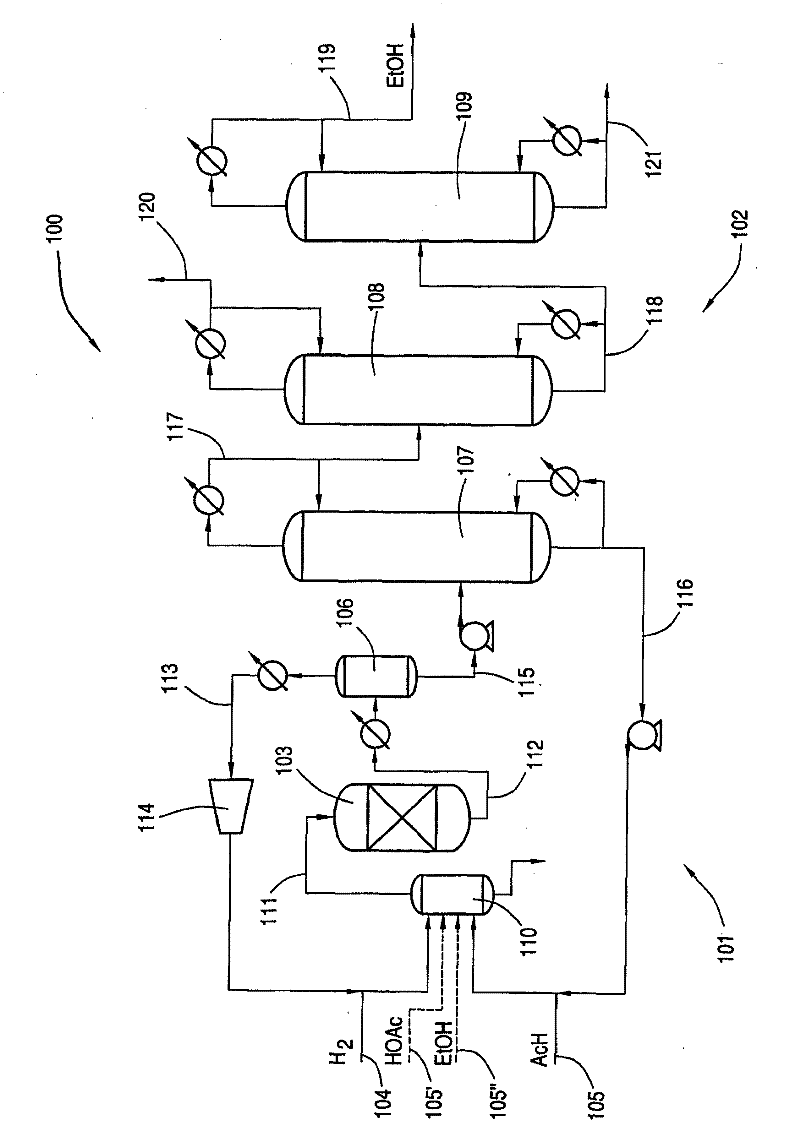

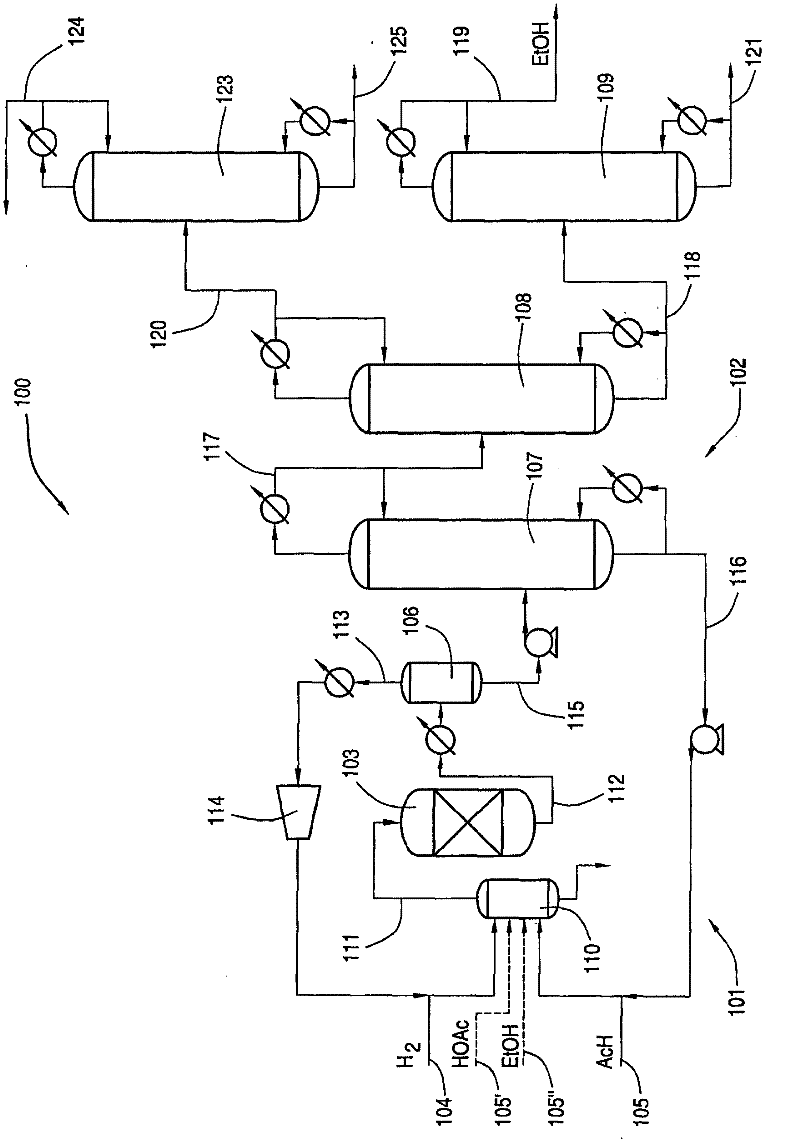

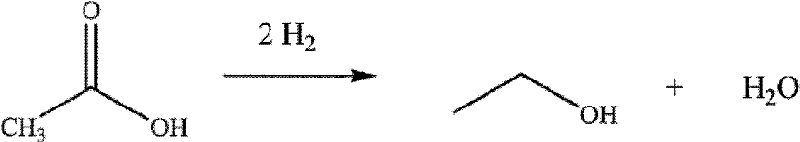

Processes for Producing Ethanol from Acetaldehyde

InactiveUS20110190551A1High selectivityPreparation by oxo-reaction and reductionOrganic compound preparationAcetic acidAcetaldehyde

In one embodiment, the invention is to a process for forming an ethanol mixture by hydrogenating an acetaldehyde feed stream in the presence of a catalyst. The acetaldehyde feed stream comprises acetaldehyde and at least one of acetic acid and ethanol. Preferably the acetaldehyde feed stream is a by-product stream from a vinyl acetate synthesis process.

Owner:CELANESE INT CORP

Catalyst for vinyl acetate synthesis and a preparation method thereof

ActiveCN103934030AHigh activityOrganic compound preparationOrganic-compounds/hydrides/coordination-complexes catalystsPtru catalystPorous carbon

The invention relates to a catalyst for vinyl acetate synthesis by use of acetylene method and a preparation method thereof, and mainly solves the problem of low activity of catalysts for vinyl acetate synthesis by use of the acetylene method in the prior art; the catalyst for vinyl acetate synthesis comprises a carrier and active components, the carrier is loaded with the active components, the active components are zinc acetate and bismuth subcarbonate, the catalyst comprises 90-180g / L of the zinc acetate and 0.1-0.3g / L of the bismuth subcarbonate, the carrier of the catalyst is a porous carbon material, the pore volume of the porous carbon material with the pore diameter of 3-10nm accounts for 20%-80% of the total pore volume, and the pore volume of the porous carbon material with the pore diameter of 30-40nm accounts for 10%-60% of the total pore volume; by use of the technical scheme, the problem of low activity of catalysts for vinyl acetate synthesis in the prior art can be well solved, and the catalyst for vinyl acetate synthesis can be used for industrial production of vinyl acetate synthesis by use of the acetylene method.

Owner:CHINA PETROLEUM & CHEM CORP +1

Catalyst for acetylene-method vinyl acetate and synthesis method of vinyl acetate

ActiveCN104437626AHigh selectivityReduce benzene contentOrganic compound preparationOrganic-compounds/hydrides/coordination-complexes catalystsBenzeneActivated carbon

The invention relates to a catalyst for acetylene-method vinyl acetate synthesis and a preparation method thereof. The catalyst is mainly used for solving the problem in the prior art that the content of a byproduct benzene in the vinyl acetate product is high. According to the catalyst for acetylene-method vinyl acetate synthesis, through adopting the technical scheme that the catalyst comprises an active ingredient which is zinc acetate, a cocatalyst which is potassium acetate and a carrier which is fullerene modified activated carbon, the problem is better solved; and the catalyst can be applied to the industrial production of acetylene-method vinyl acetate.

Owner:CHINA PETROLEUM & CHEM CORP +1

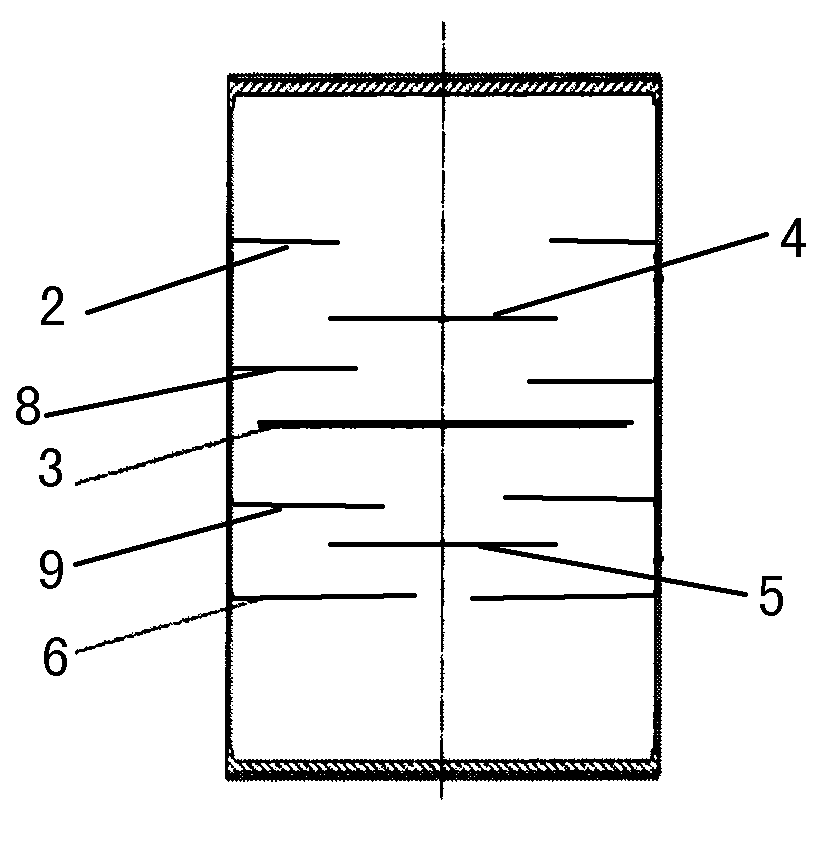

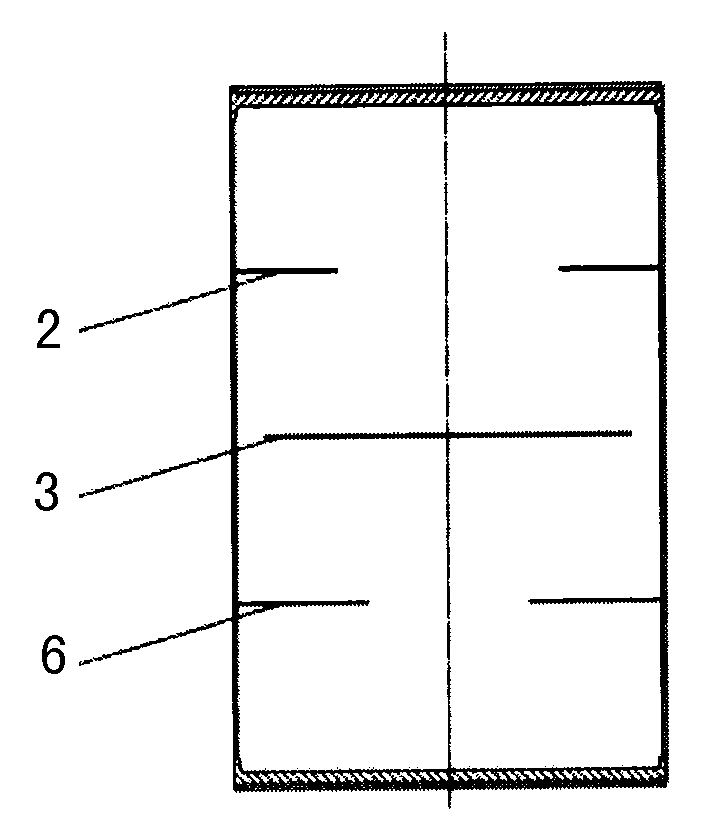

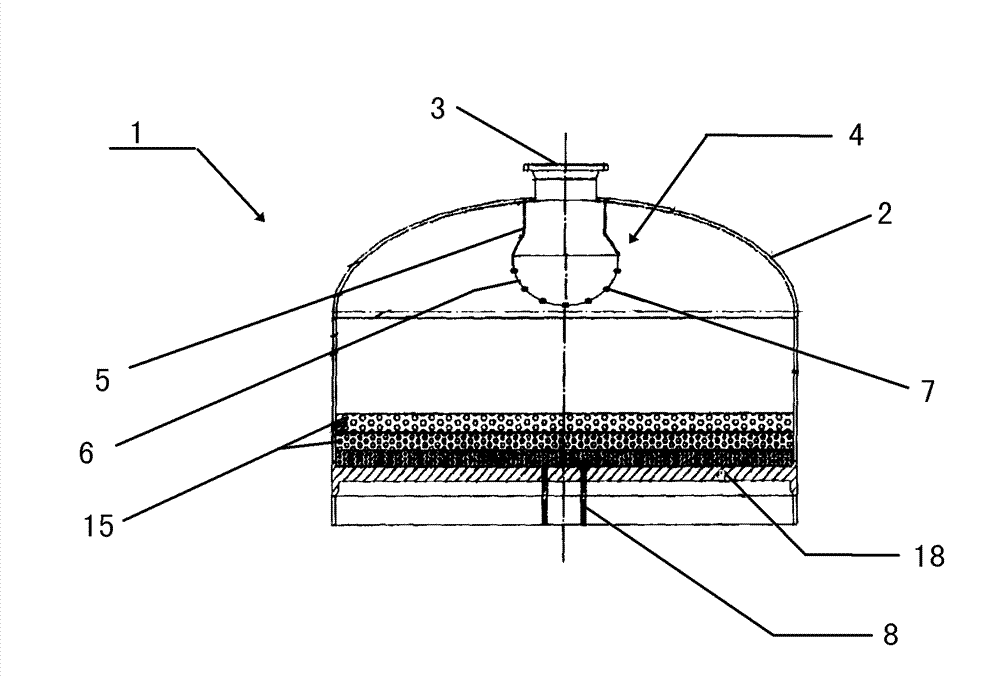

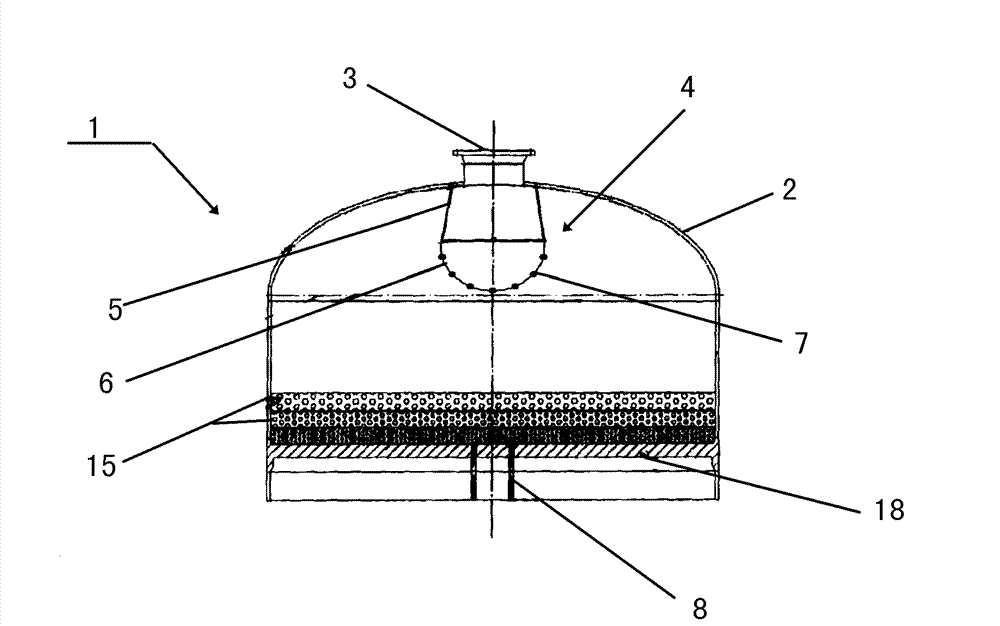

Shell side structure and shell and tube vinyl acetate synthesis reactor with same

ActiveCN102784596AImprove the cooling effectReduce radial temperature differenceOrganic compound preparationCarboxylic acid esters preparationHeat conductingEngineering

The invention relates to a novel shell side structure for a vinyl acetate synthesis reactor. An upper ring-shaped distributor and a lower ring-shaped distributor are uniformly disposed at upper and lower ends of the shell side structure along peripheral directions respectively, the upper ring-shaped distributor is provided with at least two discharge ports, the lower ring-shaped distributor is provided with at least two inlet ports, at least two discharge ports among the at least two discharge ports are in a flow communicatio with each other through an annular channel arranged in the upper ring-shaped distributor, and at least two inlet ports among the at least two inlet ports are in the flow communication with each other through an annular channel arranged in the lower ring-shaped distributor. A shell and tube vinyl acetate synthesis reactor comprising the novel shell side structure is further related. By means of the shell side structure and the shell and tube vinyl acetate synthesis reactor with the same, uniform flow and uniform heat removing of water and steam which serve as heat removing mediums can be achieved in a shell side, the radial temperature difference of the reactor can be reduced, so that the overall performance of the shell and tube vinyl acetate synthesis reactor can be improved, the synthesis reaction heat can be reasonably utilized, the operation cost is lowered, and the investment and operation costs of devices of a heat-conducting medium circulating pump and the like can be reduced.

Owner:TIANJIN UNIV

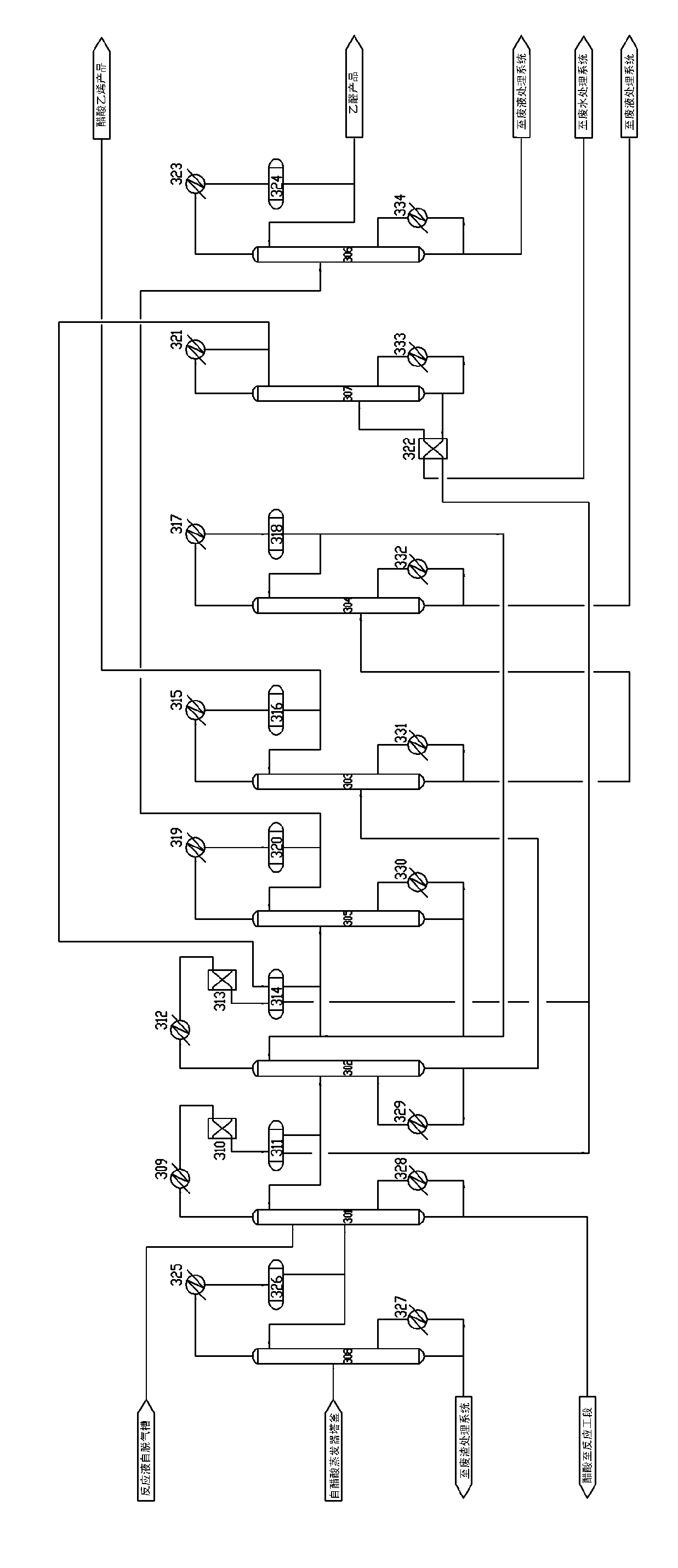

Recovery of Acetic Acid from Heavy Ends in Vinyl Acetate Synthesis Process

InactiveUS20120149939A1Organic compound preparationCarboxylic acid esters preparationAcetic acidVinyl acetate synthesis

Owner:CELANESE INT CORP

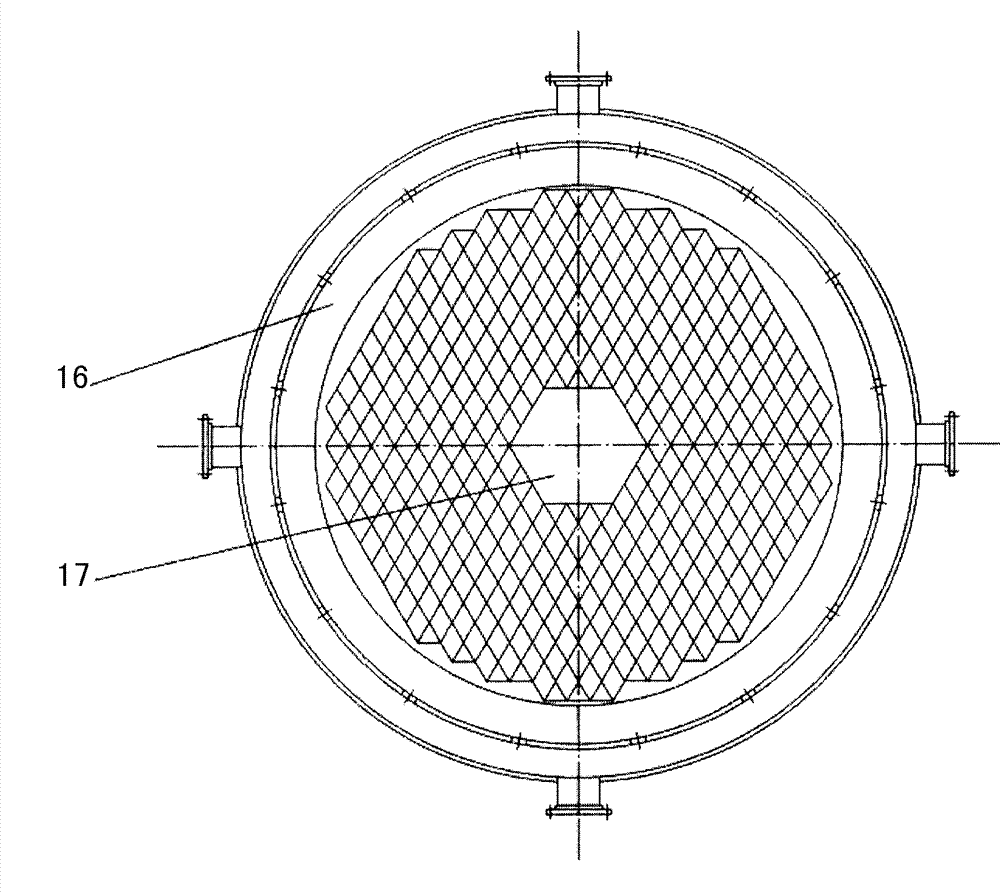

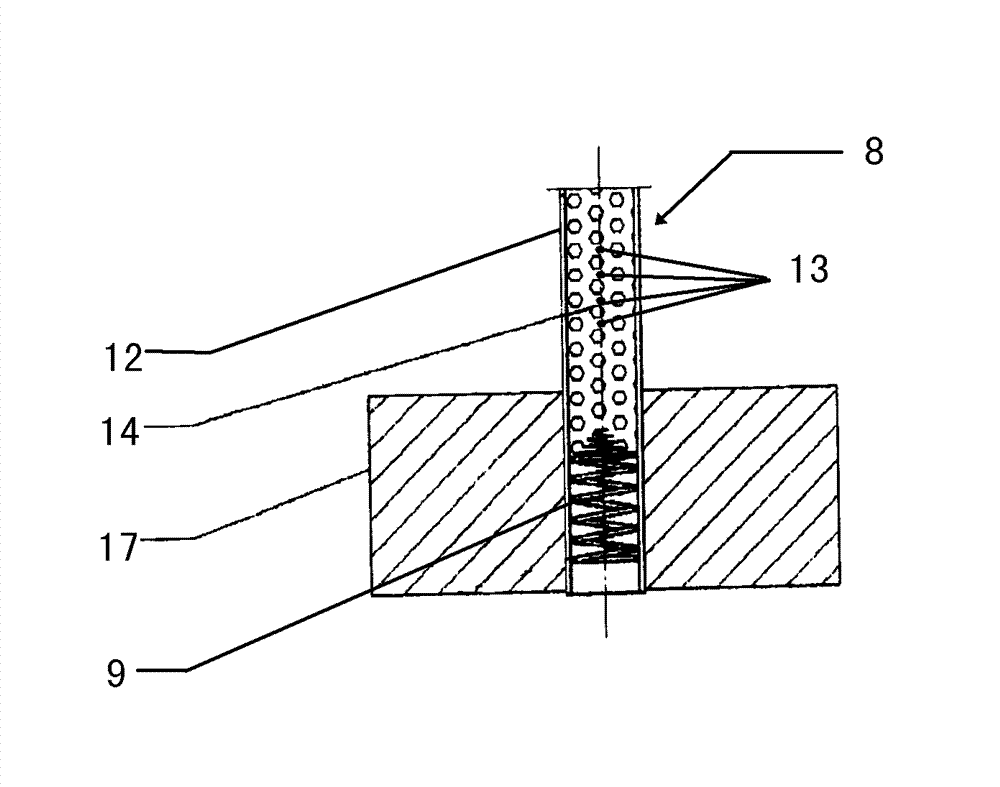

Gas distributor and vinyl acetate synthesis reactor comprising the same

InactiveCN102784603ASimple structureReduce sheddingOrganic compound preparationCarboxylic acid esters preparationProcess engineeringArea coverage

The invention relates to a gas distributor and a vinyl acetate synthesis reactor comprising the same. The gas distributor comprises an expanding current stabilization part and a spherical head, wherein the first end of the expanding current stabilization part is connected with the head of a multitubular vinyl acetate synthesis reactor, the second end corresponding to the first end of the expanding current stabilization part is connected with the spherical head of the gas distributor or the second end and the spherical head are formed integrally, the diameter of the first end of the expanding current stabilization part is larger than that of a reactor inlet, and distributing pores are uniformly arranged in the area coverage of the spherical head. According to the invention, studies by computational fluid dynamics show that by using the gas distributor with the above structure, the uniform distribution of gas can be well realized; by using the catalyst support mode of the above structure, the structure of the reactor can be greatly simplified, the manufacturing, installation, disassembly and maintenance of devices are convenient, and the incidence that the catalyst falls off and other accidents can be reduced; by using the temperature measurement mode disclosed herein, the control precision of the reactor can be well raised.

Owner:TIANJIN UNIV

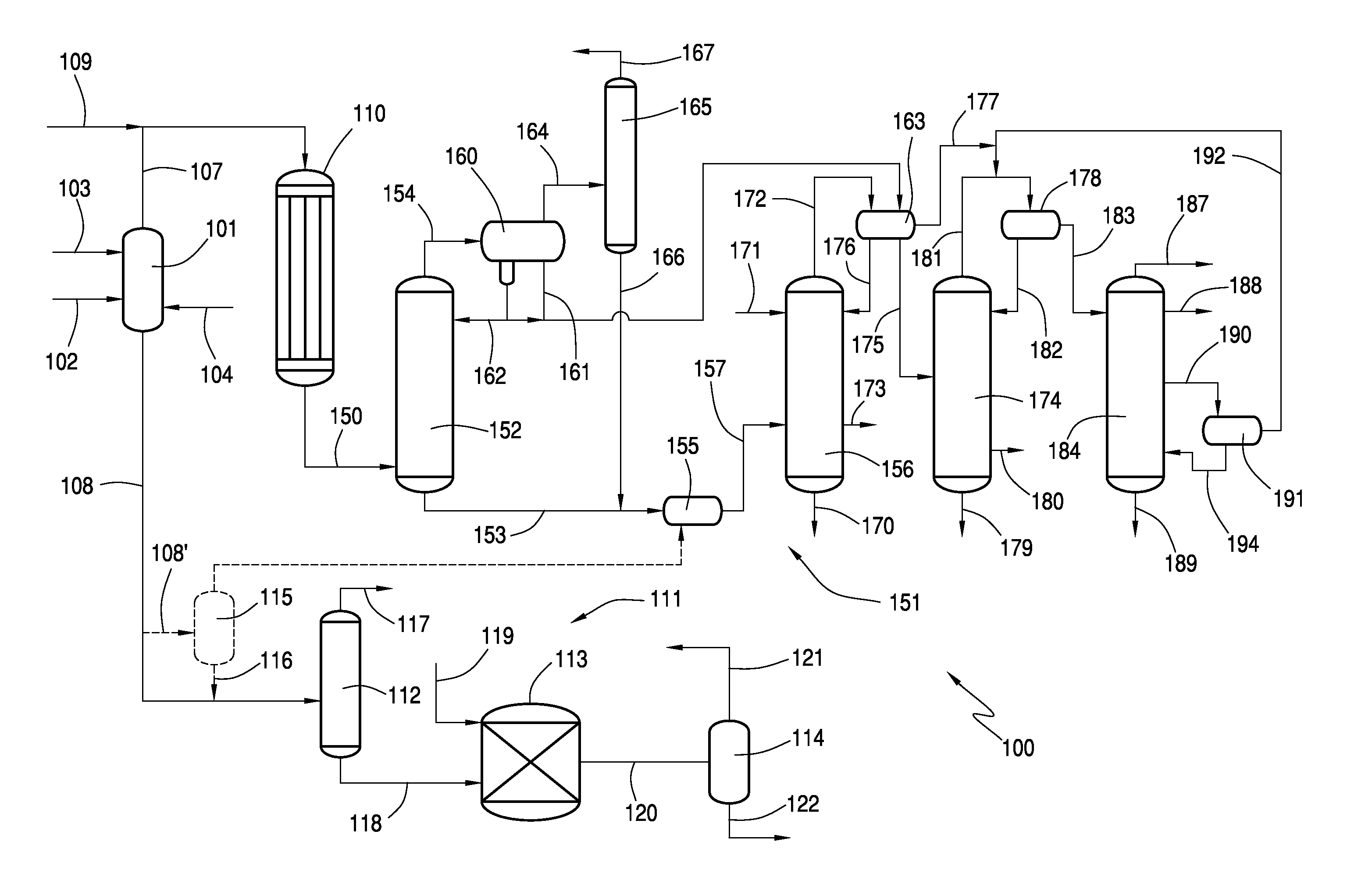

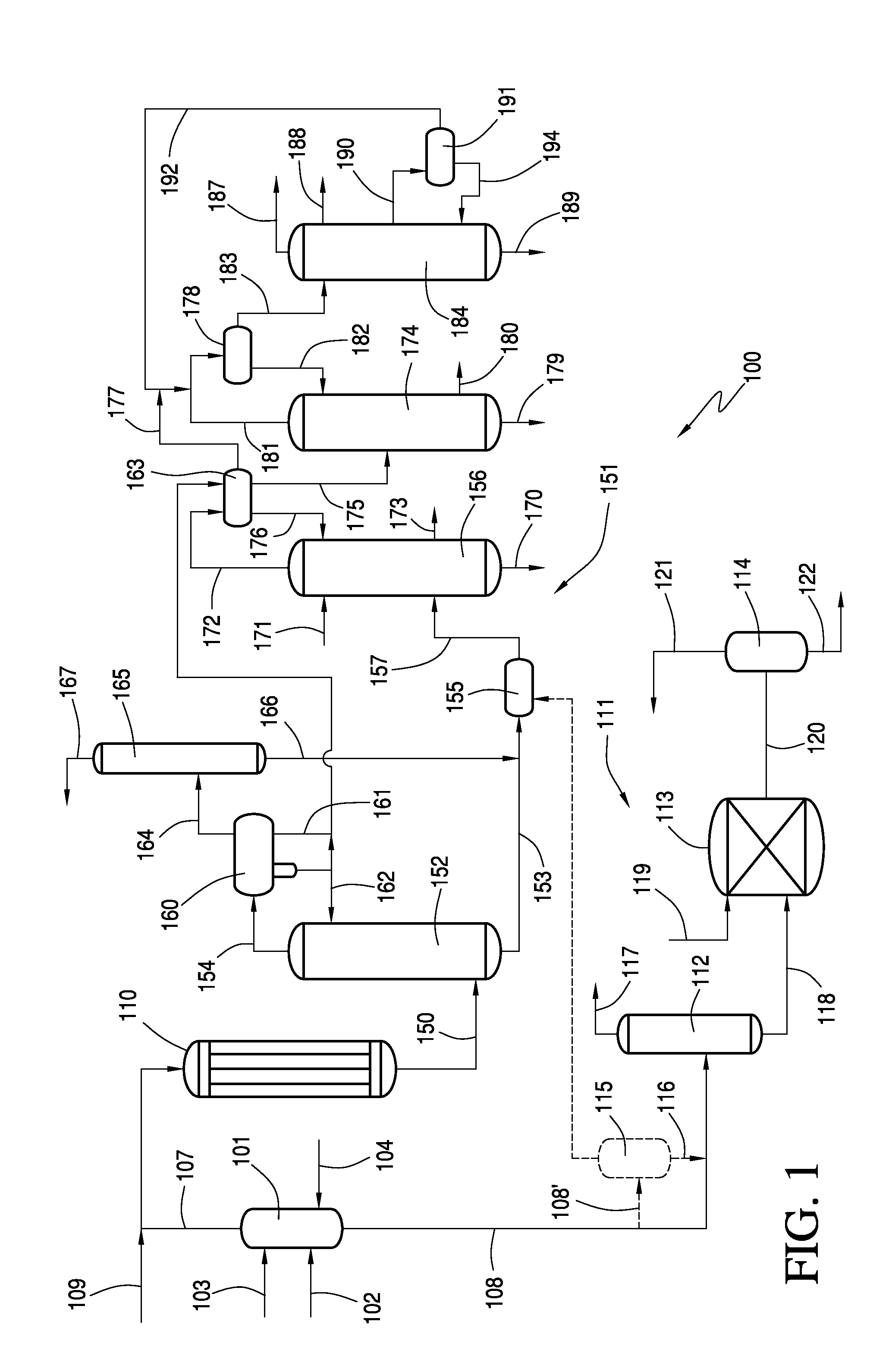

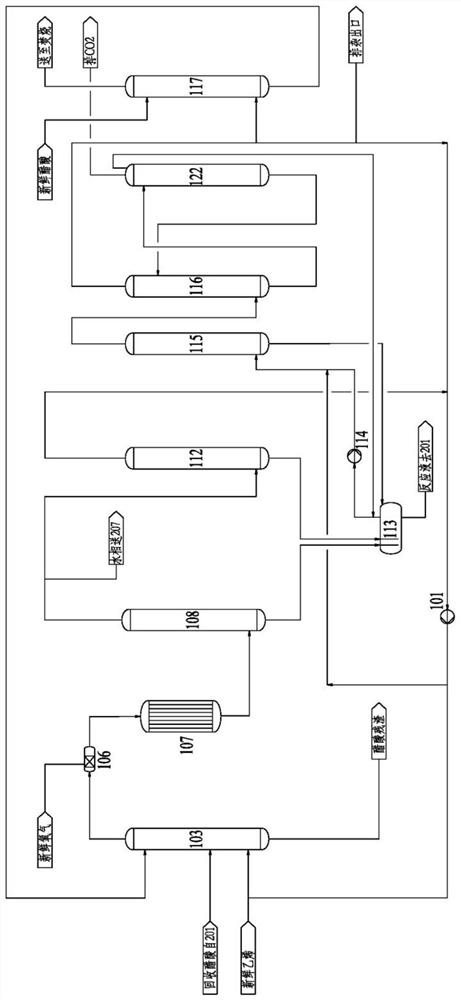

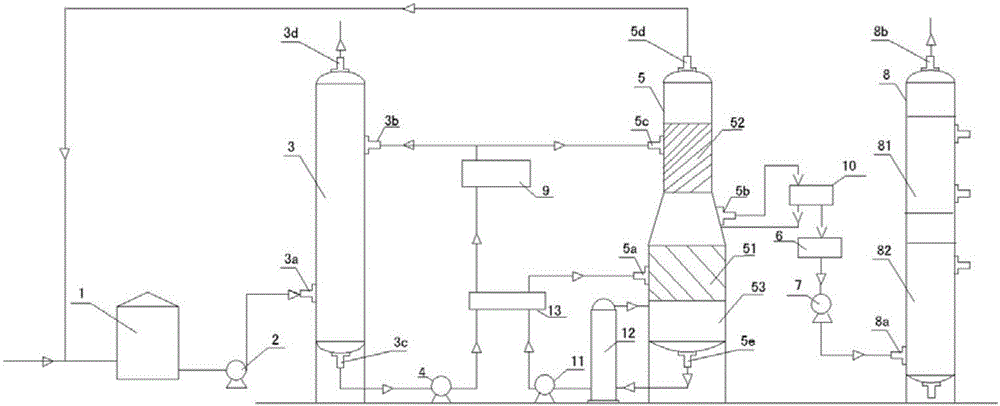

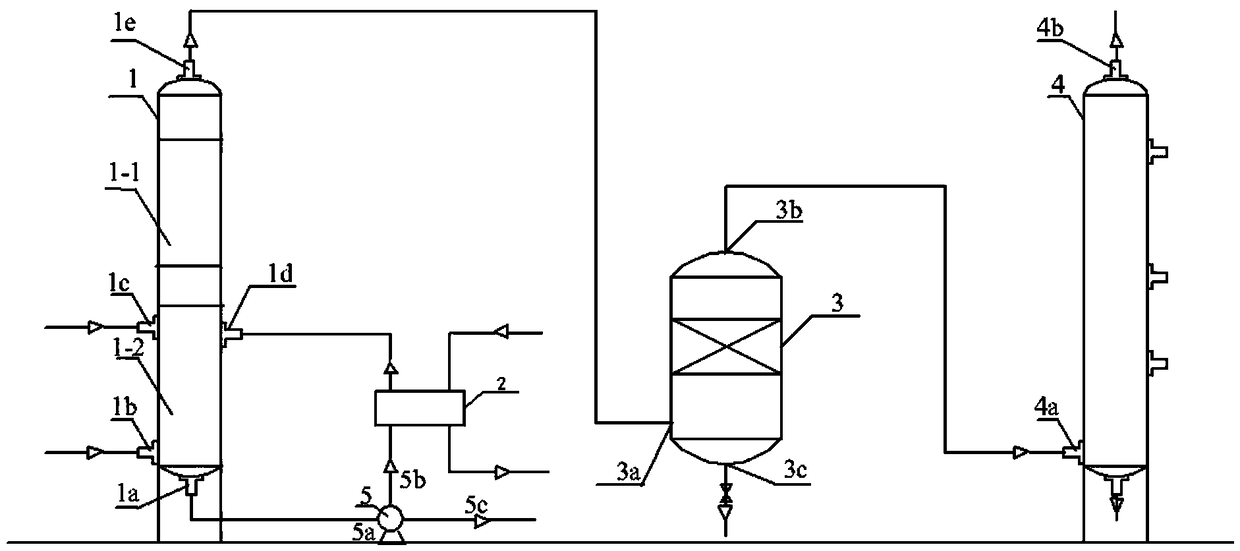

Production method of vinyl acetate

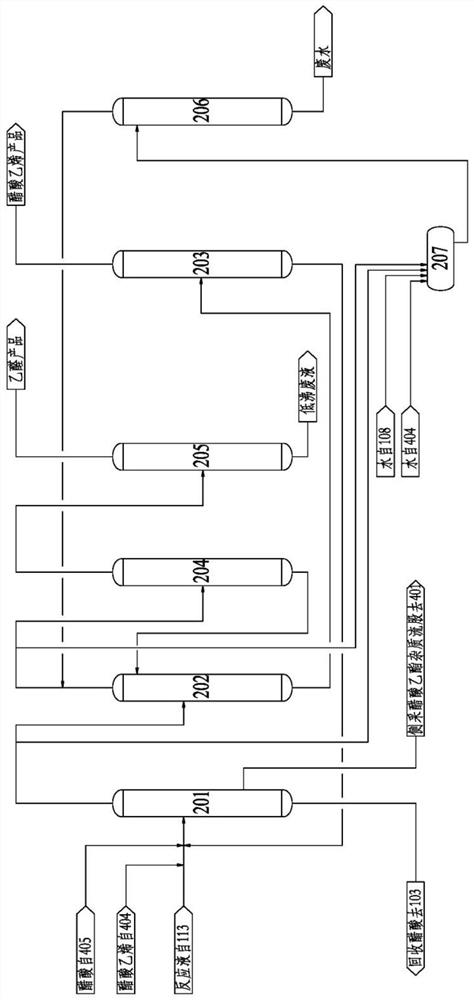

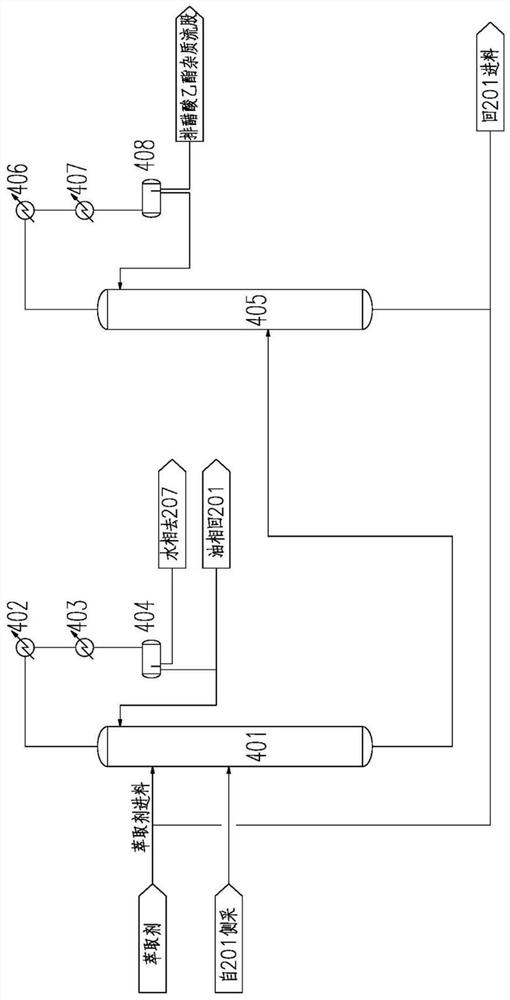

ActiveCN112209830AChange interactionReduce consumptionOrganic compound preparationCarboxylic acid esters separation/purificationExtractive distillationEthylic acid

The invention relates to a production method of vinyl acetate, which comprises a vinyl acetate synthesis process, a vinyl acetate refining process and a vinyl acetate and ethyl acetate separation process. The device comprises an acetic acid evaporator, an oxygen mixer, a vinyl acetate synthesis reactor, a first gas separation tower, a second gas separation tower, a degassing tank, a water washingtower, an absorption tower, a desorption tower, an ethylene recovery tower, a recycle gas compressor and a recovery gas compressor, and the vinyl acetate refining process comprises an acetic acid tower, a crude VAC tower, a refined VAC tower, an aldehyde ester concentration tower, an acetaldehyde tower, a dehydration tower, a water phase receiving tank, an extractive distillation tower and an acetic ether tower. In the separation process of vinyl acetate and ethyl acetate, an extractive distillation process taking acetic acid as an extracting agent is adopted. According to the method, acetic acid is adopted as an extracting agent, the content of vinyl acetate in the stream without the ethyl acetate impurities is reduced from 90% or above to 5% or below, the adopted extracting agent is acetic acid carried in the feeding stream, and the process greatly reduces the operation cost of the device.

Owner:TIANJIN UNIV

Catalyst for acetylene-method vinyl acetate and synthesis method of vinyl acetate

ActiveCN104437623AHigh selectivityReduce benzene contentOrganic compound preparationOrganic-compounds/hydrides/coordination-complexes catalystsActivated carbonBenzene

The invention relates to a catalyst for acetylene-method vinyl acetate synthesis and a preparation method thereof. The catalyst is mainly used for solving the problem in the prior art that the content of a byproduct benzene in the vinyl acetate product is high. According to the catalyst for acetylene-method vinyl acetate synthesis, through the catalyst comprising a carrier which is activated carbon, an active ingredient which is zinc acetate and a cocatalyst which is a Cr(III) salt, the problem is better solved; and the catalyst can be applied to the industrial production of synthesizing acetylene-method vinyl acetate.

Owner:CHINA PETROLEUM & CHEM CORP +1

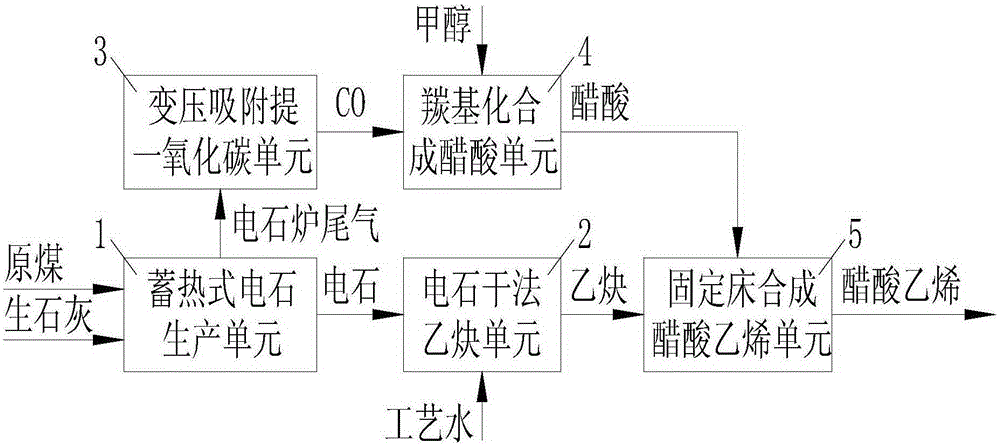

Vinyl acetate production device and method in cooperation with heat accumulating type calcium carbide production process

ActiveCN105174262AReduce production power consumptionReduce pollutionOrganic compound preparationCarboxylic acid esters preparationFixed bedEnergy conversion efficiency

The invention discloses a vinyl acetate production device and method in cooperation with a heat accumulating type calcium carbide production process. The device comprises a heat accumulating type calcium carbide production unit, wherein a calcium carbide outlet of the heat accumulating type calcium carbide production unit is connected with a calcium carbide acetylene drying unit, the calcium carbide acetylene drying unit is provided with a process water inlet, an acetylene outlet of the calcium carbide acetylene drying unit is connected with a fixed-bed vinyl acetate synthesis unit, and the fixed-bed vinyl acetate synthesis unit is provided with a vinyl acetate outlet. The heat accumulating type calcium carbide production unit is provided with a raw coal inlet and a calcined lime inlet, a calcium carbide furnace tail gas outlet of the heat accumulating type calcium carbide production unit is connected with a pressure swing adsorption carbon monoxide extracting unit, a CO outlet of the pressure swing adsorption carbon monoxide extracting unit is connected with a carbonylating acetic acid synthesis unit, and an acetic acid outlet of the carbonylating acetic acid synthesis unit is connected with the fixed-bed vinyl acetate synthesis unit. The vinyl acetate production device has the advantages of being good in raw material adaptability, low in calcium carbide production power consumption, low in pollution, high in energy conversion efficiency, high in economical efficiency and the like.

Owner:BEIJING HUAFU ENG

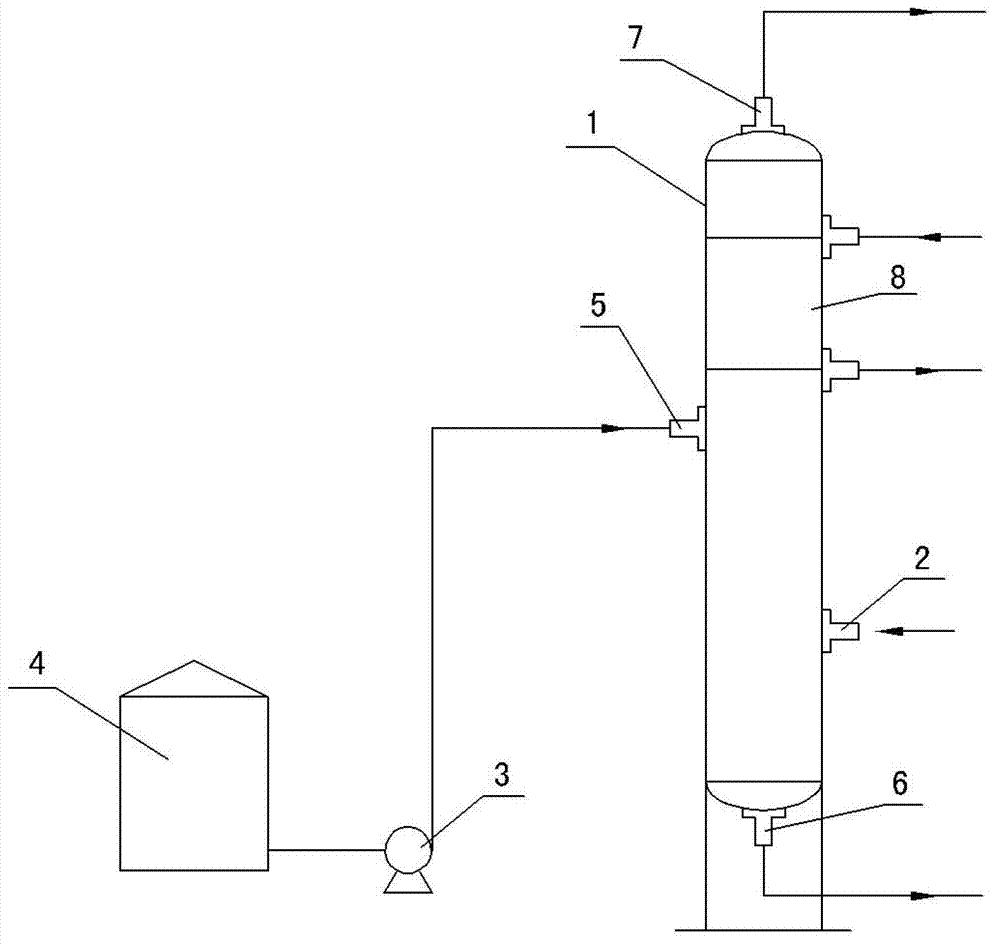

Method and device for recycling reaction offgas generated during vinyl acetate synthesis through biomass ethylene method

InactiveCN103191623AEmission reductionIncrease profitDispersed particle separationAbsorption purification/separationAcetic acidRecovery method

The invention relates to a method and a device for recycling reaction offgas generated by vinyl acetate synthesis through a biomass ethylene method. The method is characterized in that an ethylene recycling packed tower is arranged, a recycling gas from a reaction absorption tower for synthesizing vinyl acetate through the biomass ethylene method is filled from the lower part of the ethylene recycling packed tower and rises in the ethylene recycling packed tower; an acetic acid pump is utilized to pump acetic acid which is served as an absorbent through a middle acetic acid inlet in the ethylene recycling packed tower, and acetic acid is distributed on the packing surface of the ethylene recycling packed tower in a flowing manner; and the ethylene dissolved in acetic acid and acetic acid are discharged through a bottom outlet in the ethylene recycling packed tower together, and the undissolved ethylene is discharged through a top outlet in the ethylene recycling packed tower. The reaction offgas of vinyl acetate synthesizing is comprehensively recycled and utilized, so that the utilization ratio of raw materials is increased, the unit consumption of the raw materials and energy sources are lowered, and offgas emission and environmental pollution can be greatly reduced.

Owner:ANHUI WANWEI UPDATED HIGH TECH MATERIAL CO LTD +1

Processes for producing ethanol from acetaldehyde

InactiveCN102413921AOrganic compound preparationCarboxylic acid esters preparationAcetic acidAcetaldehyde

Processes for forming an ethanol mixture by hydrogenating an acetaldehyde feed stream in the presence of a catalyst. The acetaldehyde feed stream comprises acetaldehyde and at least one of acetic acid and ethanol. Preferably the acetaldehyde feed stream is a by-product stream from a vinyl acetate synthesis process.

Owner:CELANESE INT CORP

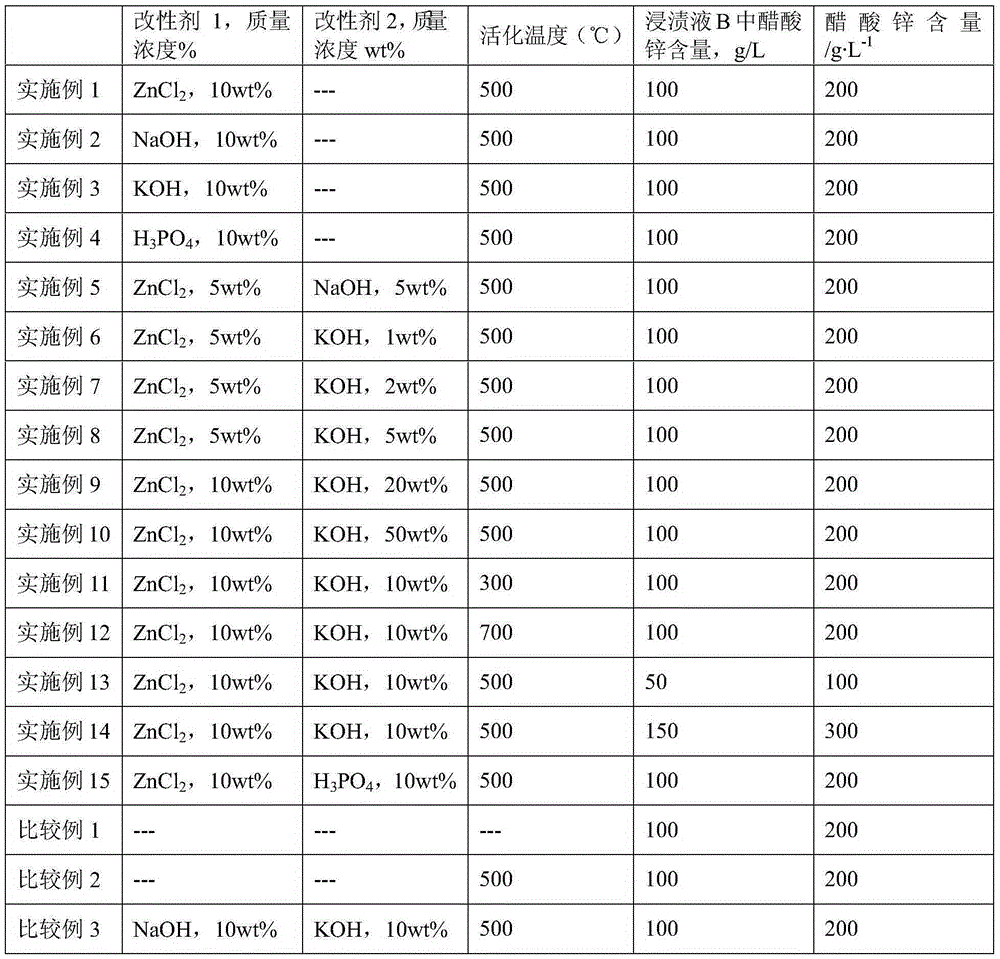

Catalyst for acetylene method vinyl acetate synthesis

ActiveCN106582853AHigh activityImprove technical effectOrganic compound preparationOrganic-compounds/hydrides/coordination-complexes catalystsSingle processActive component

The present invention relates to a catalyst for acetylene method vinyl acetate synthesis, and a preparation method thereof. A purpose of the present invention is mainly to solve the problems of low catalyst activity and low acetylene single-process conversion rate in the prior art. The technical scheme of the present invention comprises that the catalyst comprises an active component and a carrier, the active component is zinc acetate, the carrier is modified active carbon modified by a modifier, and the modifier is at least one selected from ZnCl2, KOH, NaOH, and H3PO4. With the technical scheme, the problems in the prior art are well solved. The catalyst of the present invention can be used in the industrial production of acetylene method vinyl acetate.

Owner:CHINA PETROLEUM & CHEM CORP +1

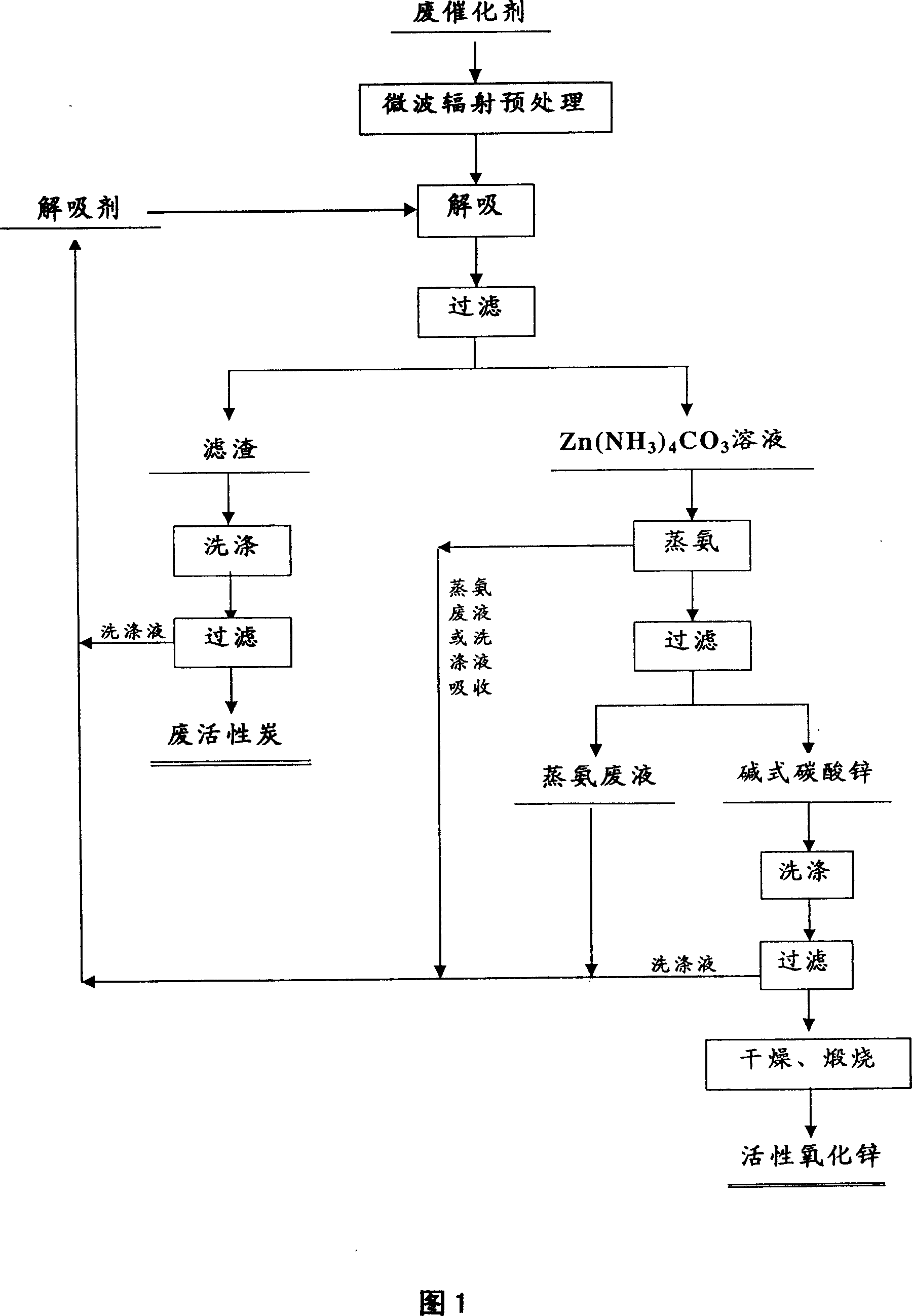

Method of desorbing zinc of waste catalyst for vinyl acetate synthesis

InactiveCN101007649AHeating evenlyHigh desorption rateZinc oxides/hydroxidesChemical recyclingSlagAmmonium hydroxide

The invention discloses a synthesizing method of zinc desorbent of waste catalyst through vinyl acetate, which comprises the following steps: adopting waste catalyst as raw material irradiated by microwave under 900-1000 deg.c; desorbing through solution of ammonia and ammonium bicarbonate under normal temperature and pressure for 3-5h; obtaining complex solution of zinc ammonia; evaporating ammonia; sintering; obtaining active zinc oxide; washing desorbed filtered slag and waste active charcoal; returning abluent to allocating course of desorbent.

Owner:KUNMING UNIV OF SCI & TECH

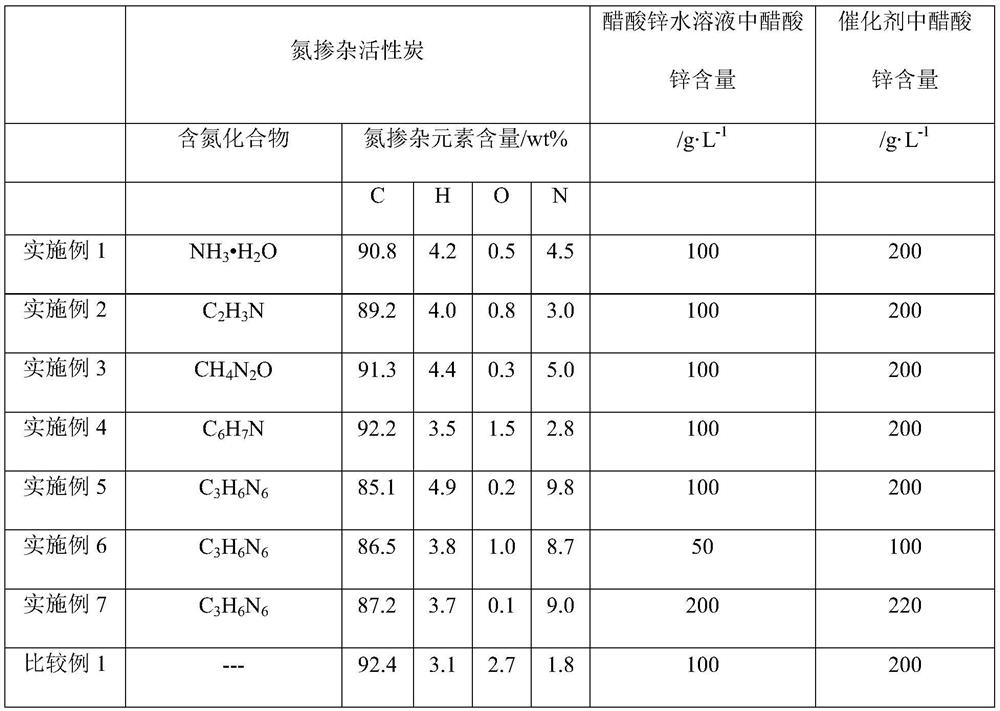

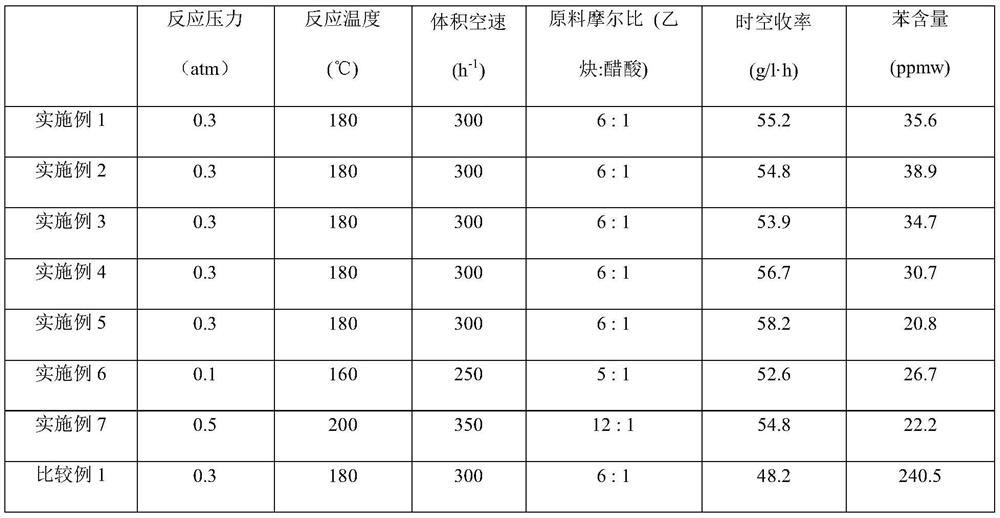

Catalyst for acetylene method vinyl acetate synthesis

PendingCN112439455AHigh activityReduce benzene contentOrganic compound preparationOrganic-compounds/hydrides/coordination-complexes catalystsActivated carbonPtru catalyst

The invention relates to a catalyst for acetylene method vinyl acetate synthesis and a preparation method thereof, and mainly aims to solve the problem of high benzene content in a vinyl acetate product in the prior art. According to the technical schemes of the invention, the catalyst for acetylene method vinyl acetate synthesis comprises an active component and a carrier; the active component iszinc acetate; the carrier is nitrogen-doped activated carbon; the content of the N element in the carrier is 2.8-10wt%; and therefore, the problem is better solved, and the method can be used for industrial production of acetylene-method vinyl acetate.

Owner:CHINA PETROLEUM & CHEM CORP +1

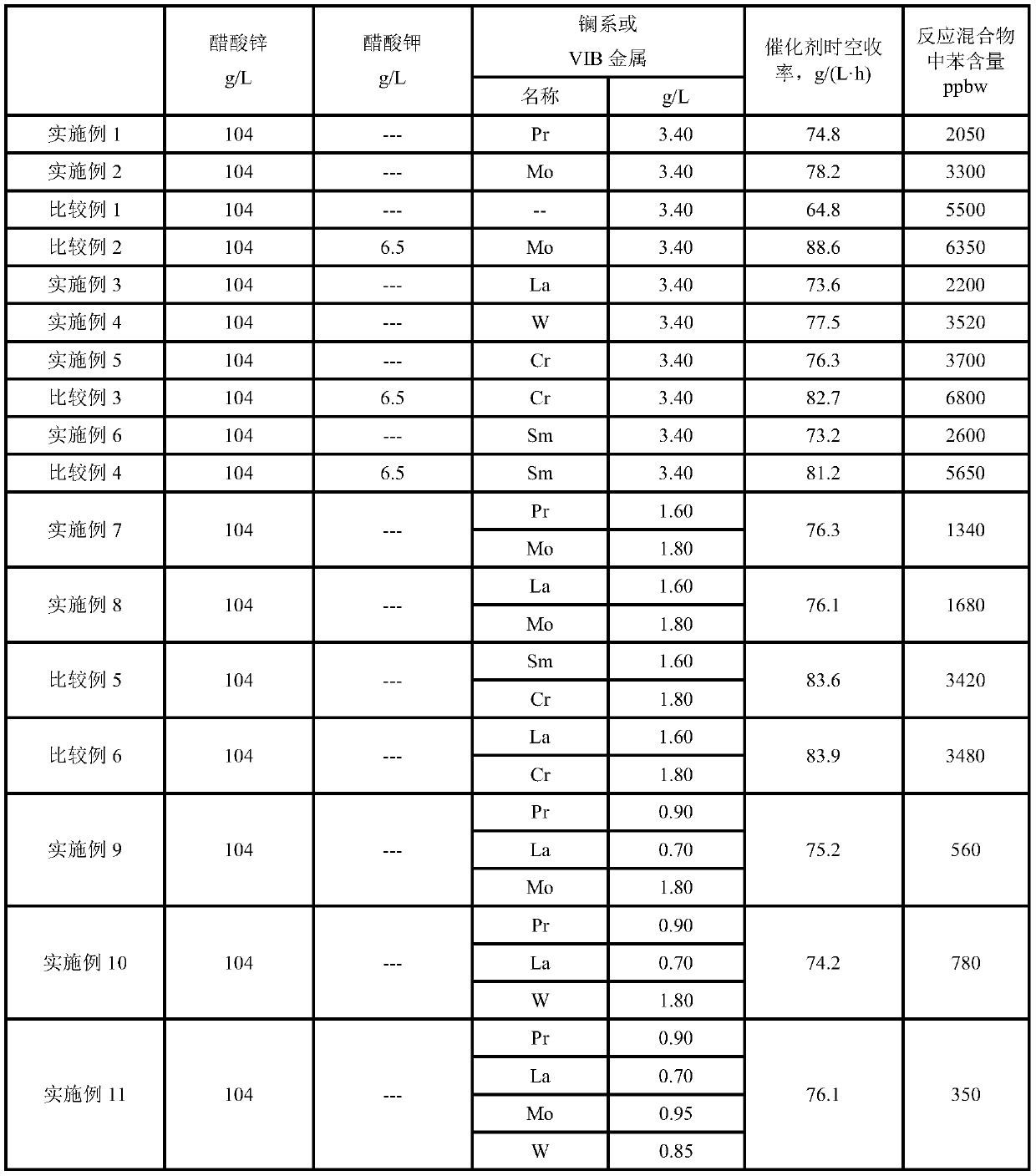

Catalyst for Synthesis of Vinyl Acetate by Acetylene Process

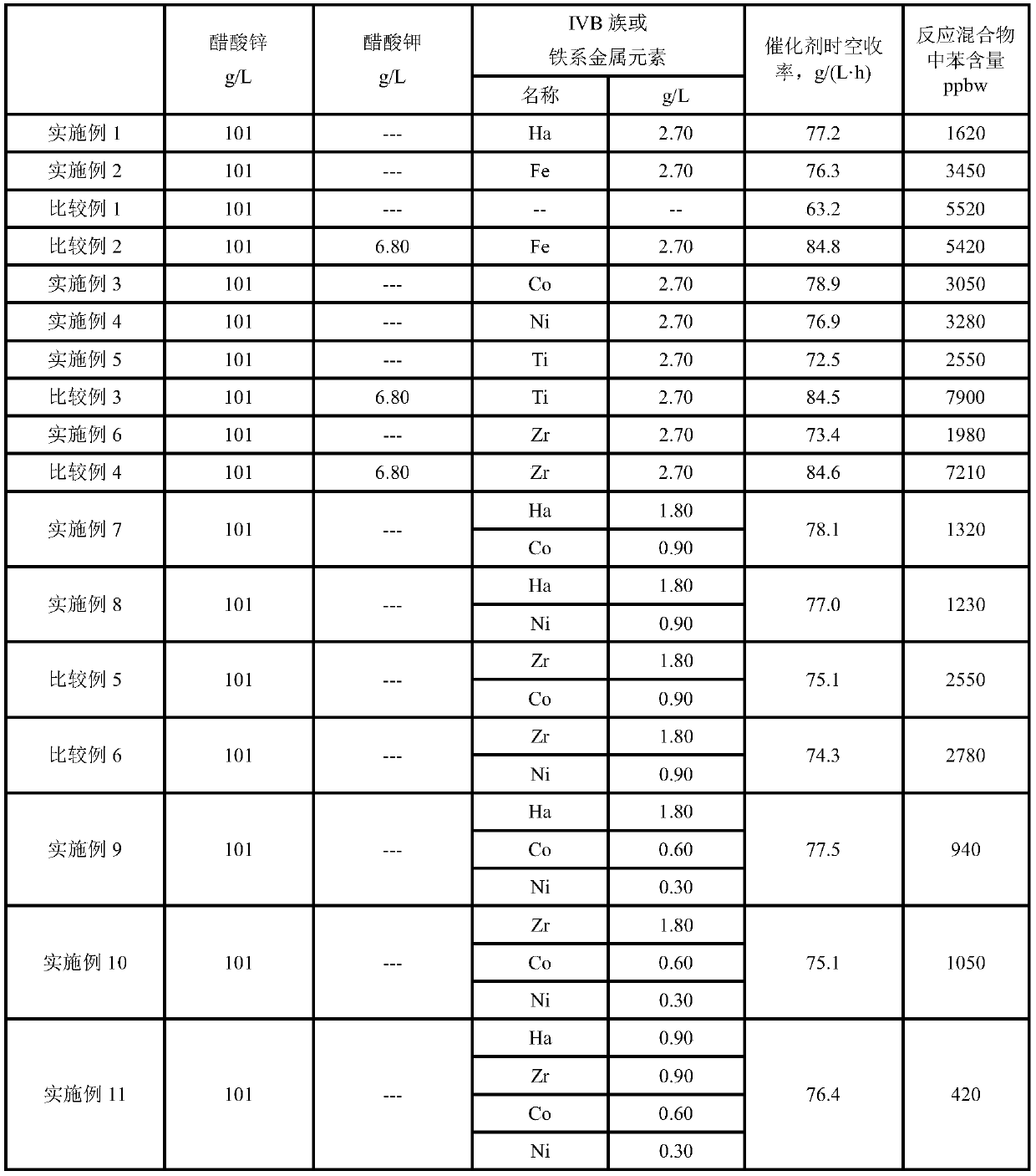

ActiveCN107774320BReduce benzene contentOrganic compound preparationOrganic-compounds/hydrides/coordination-complexes catalystsBenzeneActivated carbon

The invention relates to a catalyst for synthetizing vinyl acetate by an acetylene method and a preparation method thereof, and mainly solves the problem that in the prior art, the content of by-products of benzene is high. The catalyst for synthetizing vinyl acetate by the acetylene method has the technical scheme that the catalyst uses active carbon as a carrier; active ingredients include zincacetate and cocatalysts; the cocatalysts include at least one metal element selected from lanthanide series metal elements and at least one metal element in VIB elements. The problem is better solved;the catalyst can be used for industrial production of acetylene method vinyl acetate synthesis.

Owner:CHINA PETROLEUM & CHEM CORP +1

Method and device for recycling acetylene during production process of vinyl acetate

ActiveCN105061133AIncrease profitReduce unit consumptionHydrocarbon purification/separationHydrocarbonsAcetaldehydeVinyl acetate synthesis

The invention discloses a method and device for recycling acetylene during the production process of vinyl acetate. The method is characterized in that an absorbing tower, a degassing tower, and a water washing tower are arranged, the reaction gas discharged from the top of a gas separation tower in the vinyl acetate synthesis step is subjected to an acetylene absorbing treatment, an acetylene releasing treatment, and an acetylene water washing treatment in sequence so as to remove the inert gas and acetaldehyde in the reaction gas, and acetylene with a concentration of 98% or more is obtained. The acetylene in the production process of vinyl acetate is comprehensively recycled and utilized, the utilization rate of raw material is improved, the consumption of raw materials and energy is reduced, and the cost is greatly reduced.

Owner:ANHUI WANWEI UPDATED HIGH TECH MATERIAL CO LTD

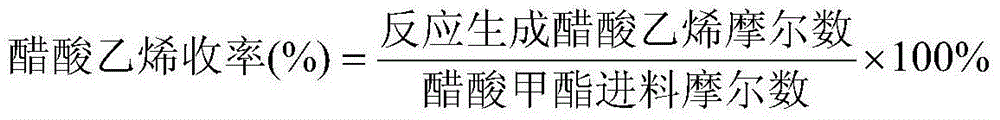

Vinyl acetate synthesis method

ActiveCN105585491AHigh activityImprove stabilityOrganic compound preparationCarboxylic acid esters preparationActive componentMethyl acetate

The invention relates to a vinyl acetate synthesis method. When vinyl acetate is prepared from methyl acetate through the route of carbonylation and cracking, vinyl acetate yield and selectivity are low. The invention mainly aims at solving the problems. The vinyl acetate synthesis method comprises the following steps: methyl acetate carbonylation is carried out, such that ethylene diacetate is obtained; and ethylene diacetate is cracked, such that vinyl acetate is obtained. A carbonylation catalyst adopts SiO2, Al2O3 or a mixture thereof as a carrier, and has active components comprising rhodium, alkali metal and at least one metal element selected from IVA and VA. With the technical scheme, the technical problem is well solved. The method can be used in industrial production of vinyl acetate.

Owner:CHINA PETROLEUM & CHEM CORP +1

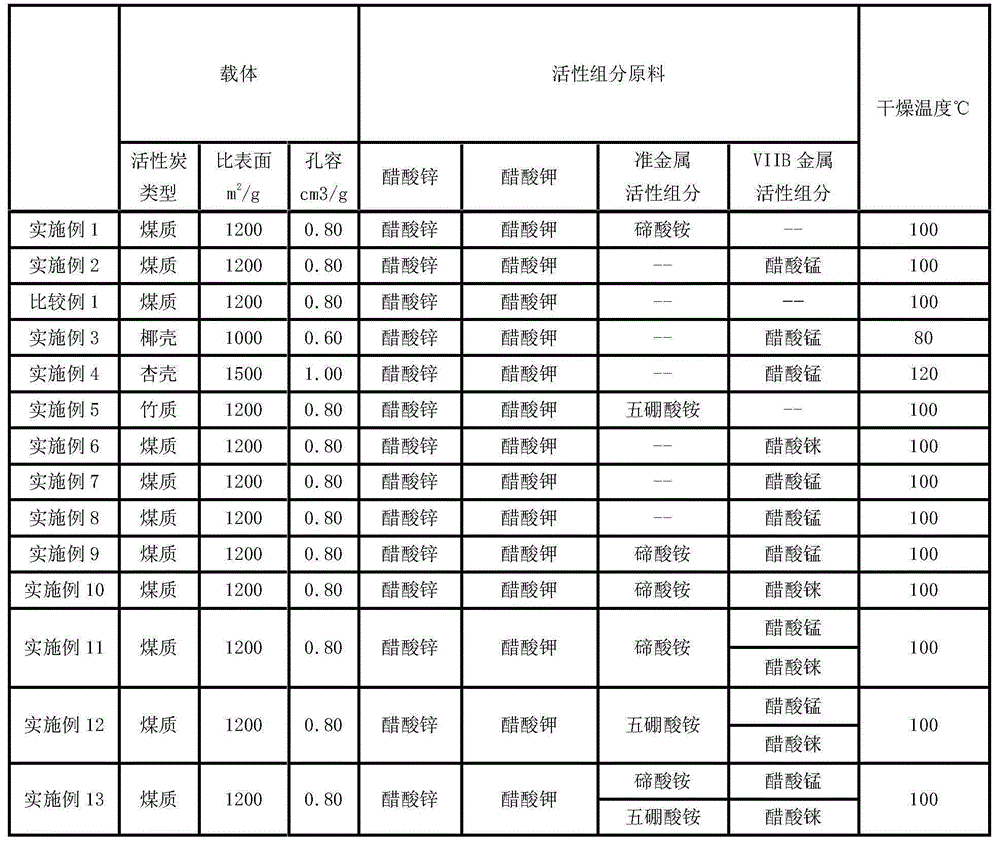

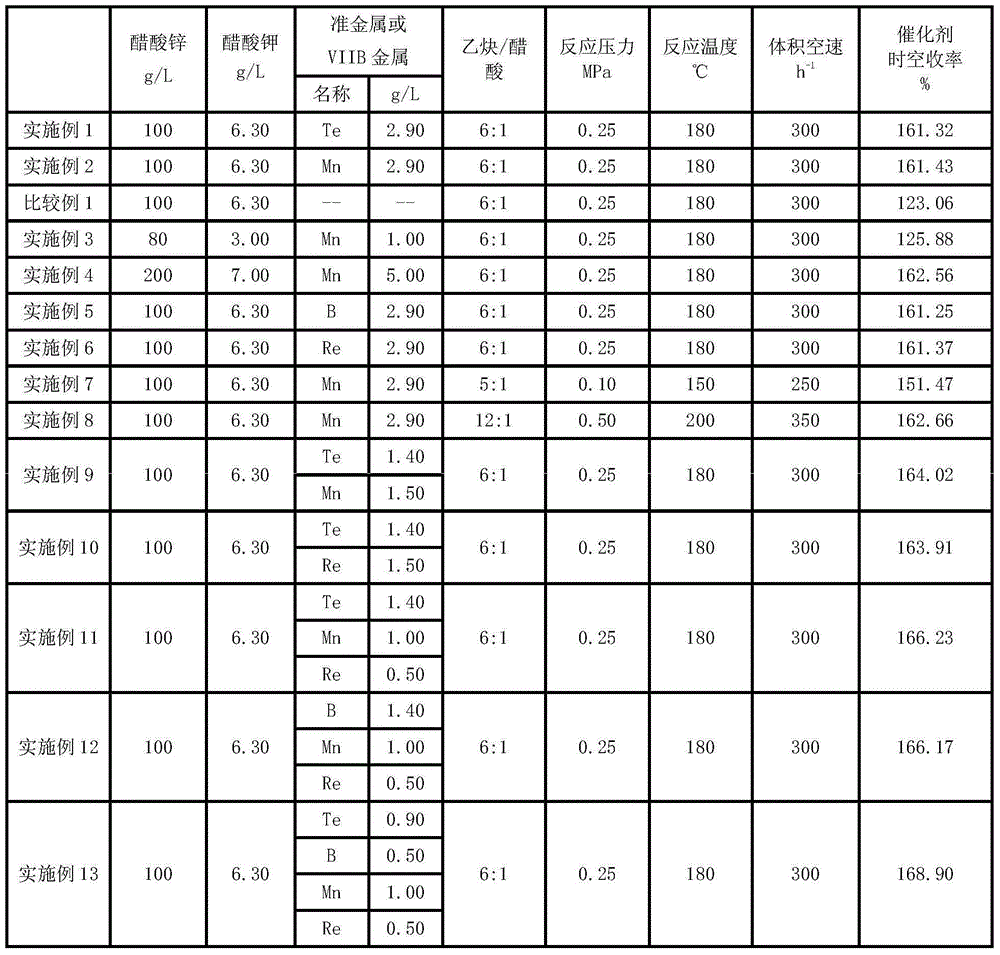

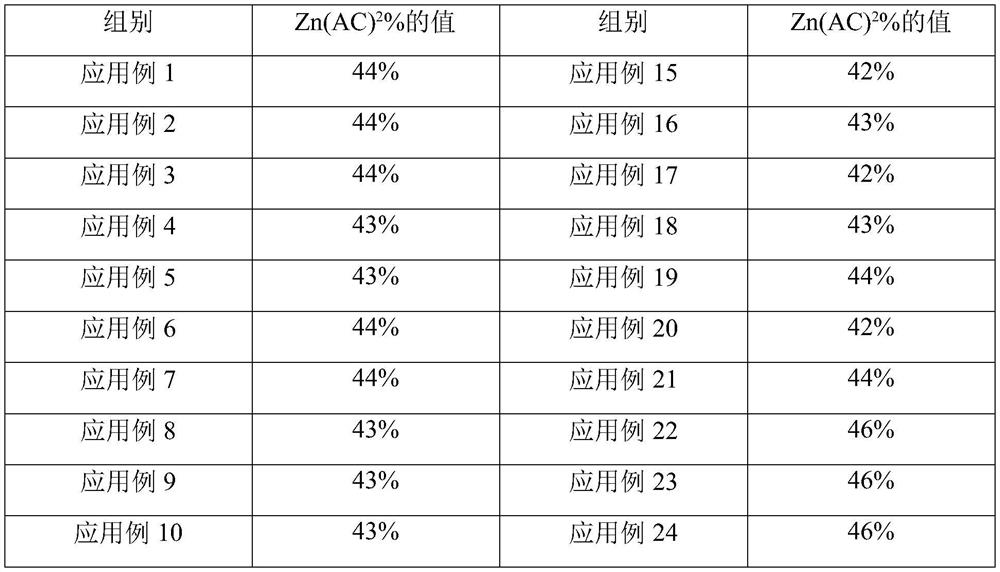

Catalyst for production of acetylene method vinyl acetate

ActiveCN106423221AHigh activityImprove stabilityOrganic compound preparationCarboxylic acid esters preparationGas phaseActive component

The present invention relates to a catalyst for production of acetylene method vinyl acetate. A purpose of the present invention is to mainly solve the problem of not high activity of the acetylene gas phase catalyst in the prior art. The technical scheme of the present invention is that the catalyst uses active carbon as the carrier, and the active components comprise zinc acetate, potassium acetate, and a compound of at least an element selected from metalloid or group VIIB metal. With the technical scheme of the present invention, the problem in the prior art is solved. The catalyst of the present invention can be used for the vinyl acetate synthesis through the acetylene gas phase method in the industrial production.

Owner:CHINA PETROLEUM & CHEM CORP +1

Production process of activated carbon-based carbon, catalyst applying activated carbon-based carbon and production process of catalyst

PendingCN114768785ALarge specific surface areaHigh purityOrganic compound preparationOrganic-compounds/hydrides/coordination-complexes catalystsActivated carbonPtru catalyst

The invention discloses a production process of activated carbon-based carbon, a catalyst applying the activated carbon-based carbon and a production process of the catalyst, and relates to the technical field of catalysts. The production process of the activated carbon-based carbon comprises the steps of taking of the base carbon, pre-acidification treatment, alkalization treatment, pressurization for air isolation, composite activation, acid washing and alkali washing. The production process of the catalyst using the activated carbon-based carbon comprises the steps of a loading stage, finished product obtaining and the like. The vinyl acetate synthesis catalyst is prepared by using the production process of the activated carbon-based carbon catalyst. According to the present invention, the specific surface area of the activated carbon-based carbon can be easily increased, the purity of the activated carbon-based carbon can be improved, such that the product performance of the activated carbon-based carbon can be improved, and the catalyst prepared from the activated carbon-based carbon has high catalytic activity.

Owner:MULINSEN ACTIVATED CARBON JIANGSU

Catalyst used for acetylene method vinyl acetate synthesis

ActiveCN103962179AHigh activityImprove technical effectOrganic compound preparationOrganic-compounds/hydrides/coordination-complexes catalystsActivated carbonPolymer science

The invention relates to a catalyst used for acetylene method vinyl acetate synthesis, and mainly solves a problem of low catalyst activity existing in the prior art. The catalyst used for acetylene method vinyl acetate synthesis comprises an active carbon carrier, zinc acetate, diether and aromatic acid ester, and the content of zinc acetate in the catalyst is 60-180g / L. The catalyst can well solve the problem, and can be used in the industrial production of the acetylene method vinyl acetate synthesis.

Owner:CHINA PETROLEUM & CHEM CORP +1

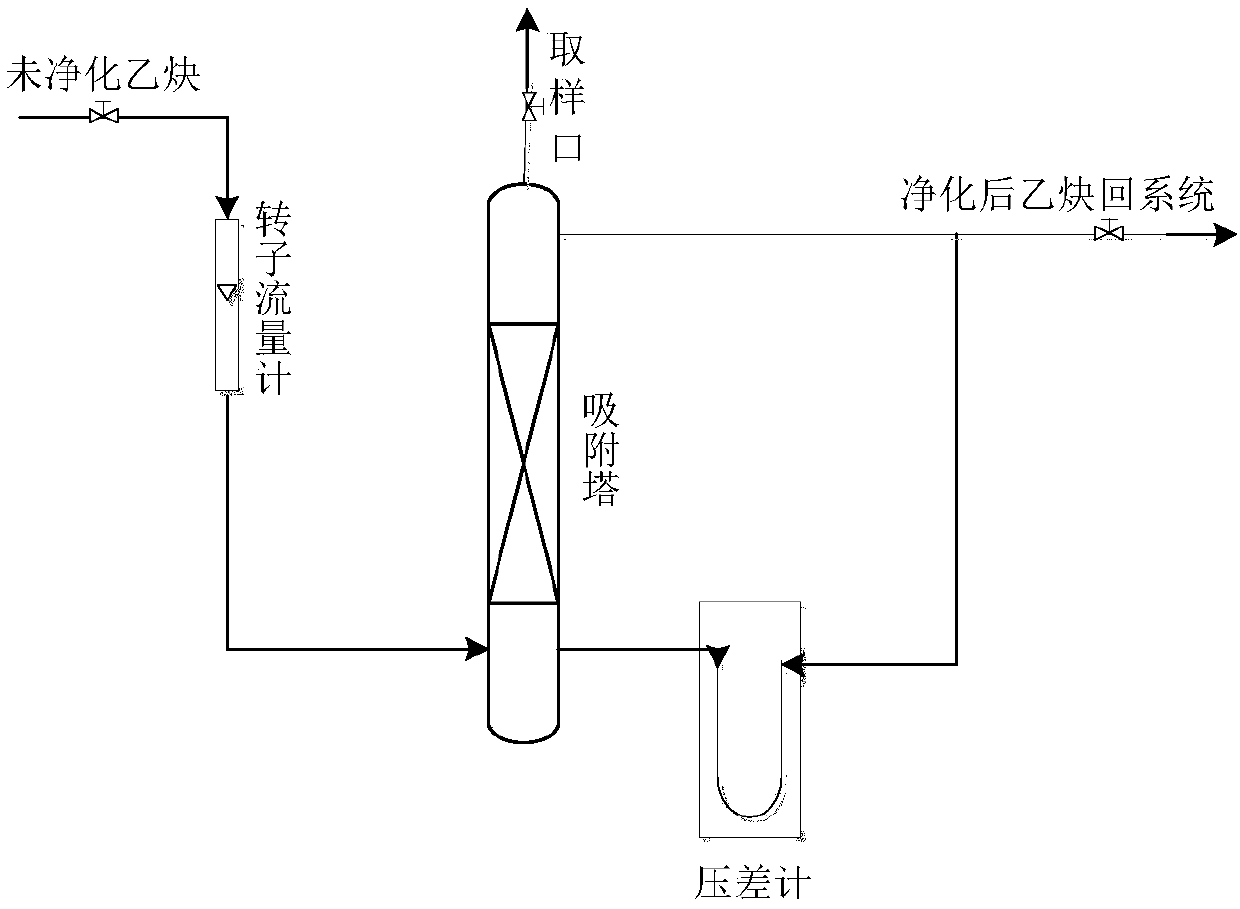

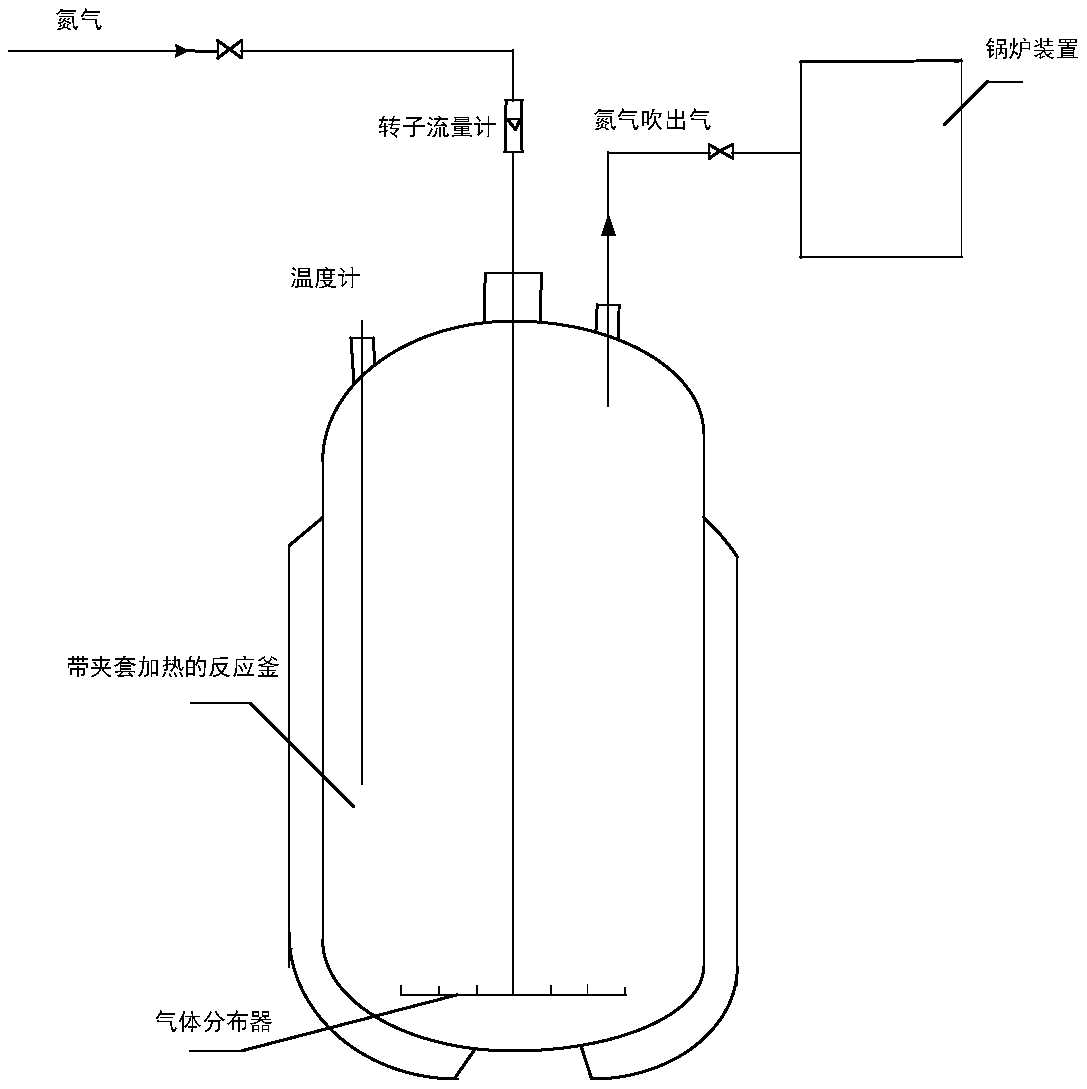

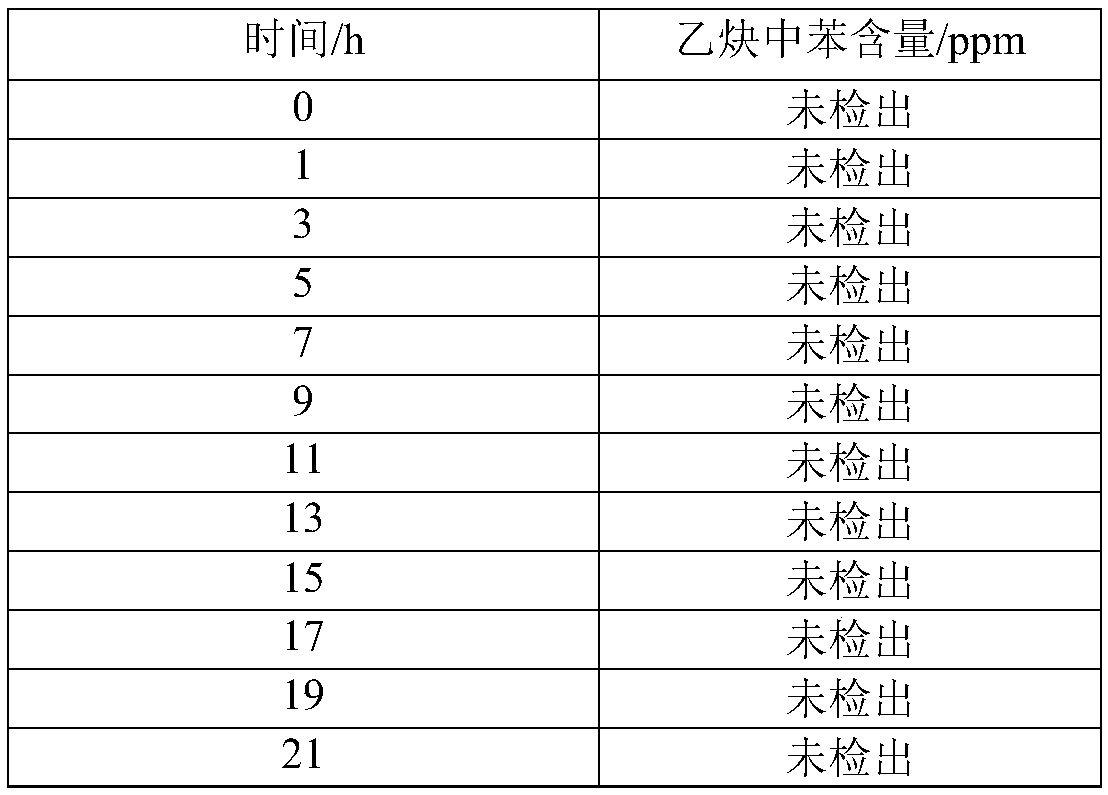

Method of adsorbing and desorbing benzene in acetylene

PendingCN110871013AReduce benzene contentReduce dosageGas treatmentDispersed particle separationBenzeneActivated carbon

The invention belongs the technical field of using methods such as adsorption, regeneration or reactivation for separating free carbon through chemical or physical change on the substance, and particularly relates to a method of adsorbing and desorbing benzene in acetylene, including steps of: A) feeding non-purified acetylene in an adsorption column loaded with activated carbon, and feeding the purified acetylene back to a vinyl acetate synthesis system; B) desorption regeneration of activated carbon: placing the activated carbon, after adsorption saturation, in a reaction kettle equipped with a heating jacket for desorption regeneration, wherein inert gas is fed to the bottom of the reaction kettle and is connected with a gas distributor at the bottom of the reaction kettle, so that whenthe reaction kettle is heated by the jacket, the benzene and water in the activated carbon are vaporized and are blown out by the inert gas, and feeding the blow-out gas to a boiler for combustion.The method can remove the benzene and saturation water in acetylene, wherein the activated carbon after adsorption saturation can be regenerated and recycled after treatment.

Owner:CHINA PETROLEUM & CHEM CORP +2

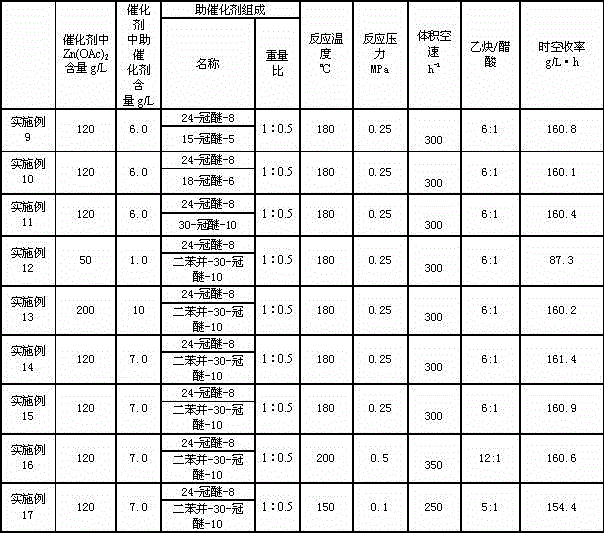

Vinyl acetate catalyst, preparation method and vinyl acetate synthesis method

ActiveCN104549496AHigh space-time yieldHigh activityOrganic compound preparationOrganic-compounds/hydrides/coordination-complexes catalystsActivated carbonPolymer science

The invention relates to a vinyl acetate catalyst, a preparation method and a vinyl acetate synthesis method, mainly used for solving the problem in the prior art that the activity of the catalyst is not high. The vinyl acetate catalyst is prepared by adopting an acetylene method and adopting active carbon as a carrier body. The catalyst comprises the following active components: 50g / L to 200g / L of zinc acetate and 1.0g / L to 10g / L of a co-catalyst. By adopting the technical scheme that the co-catalyst is selected from at least one of 18-crown ether-6, 15-crown ether-5, 24-crown ether-8, 30-crown ether-10, dibenzo-30-crown ether-10 or other derivatives adopting the 18-crown ether-6, 15-crown ether-5, 24-crown ether-8, 30-crown ether-10 and dibenzo-30-crown ether-10 as a nuclear parent, the problem can be well solved. The vinyl acetate catalyst can be used for the industrial production of the vinyl acetate synthesis in the acetylene method.

Owner:CHINA PETROLEUM & CHEM CORP +1

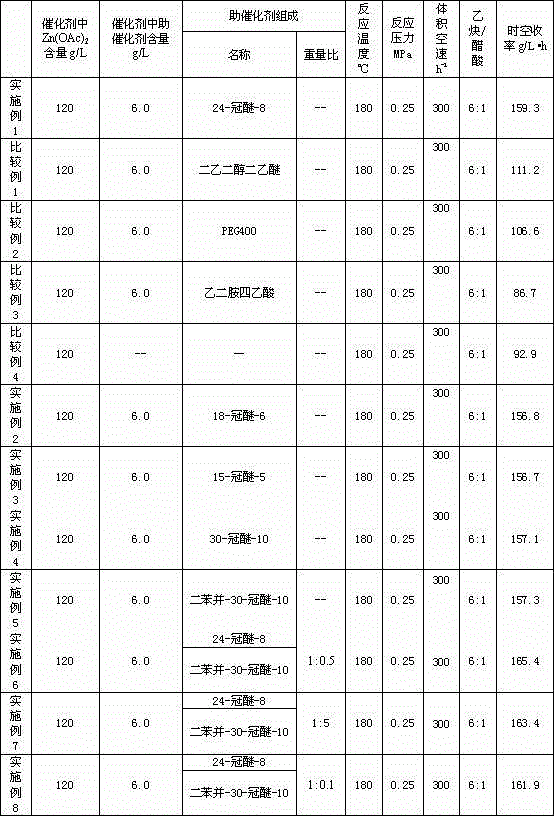

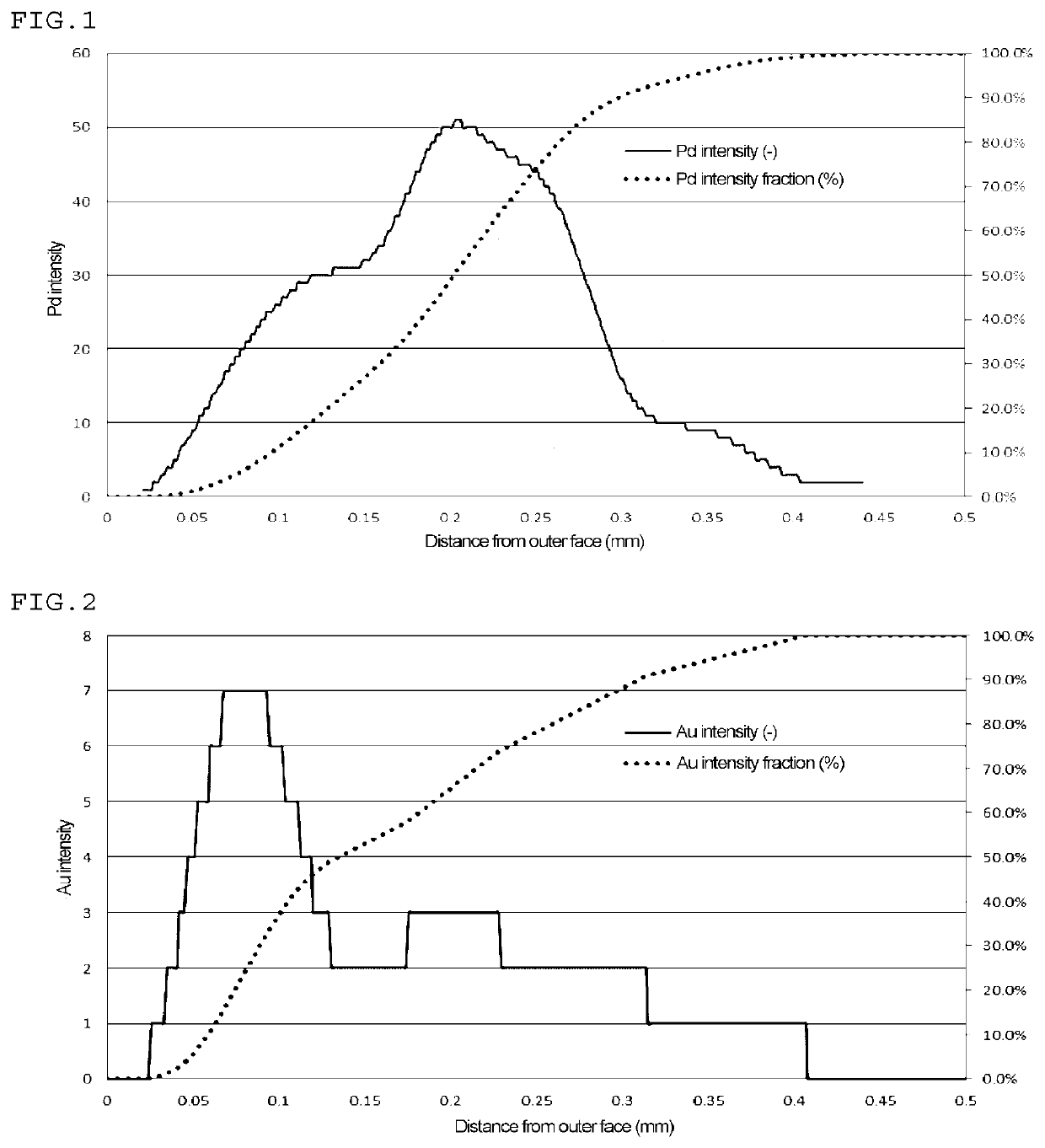

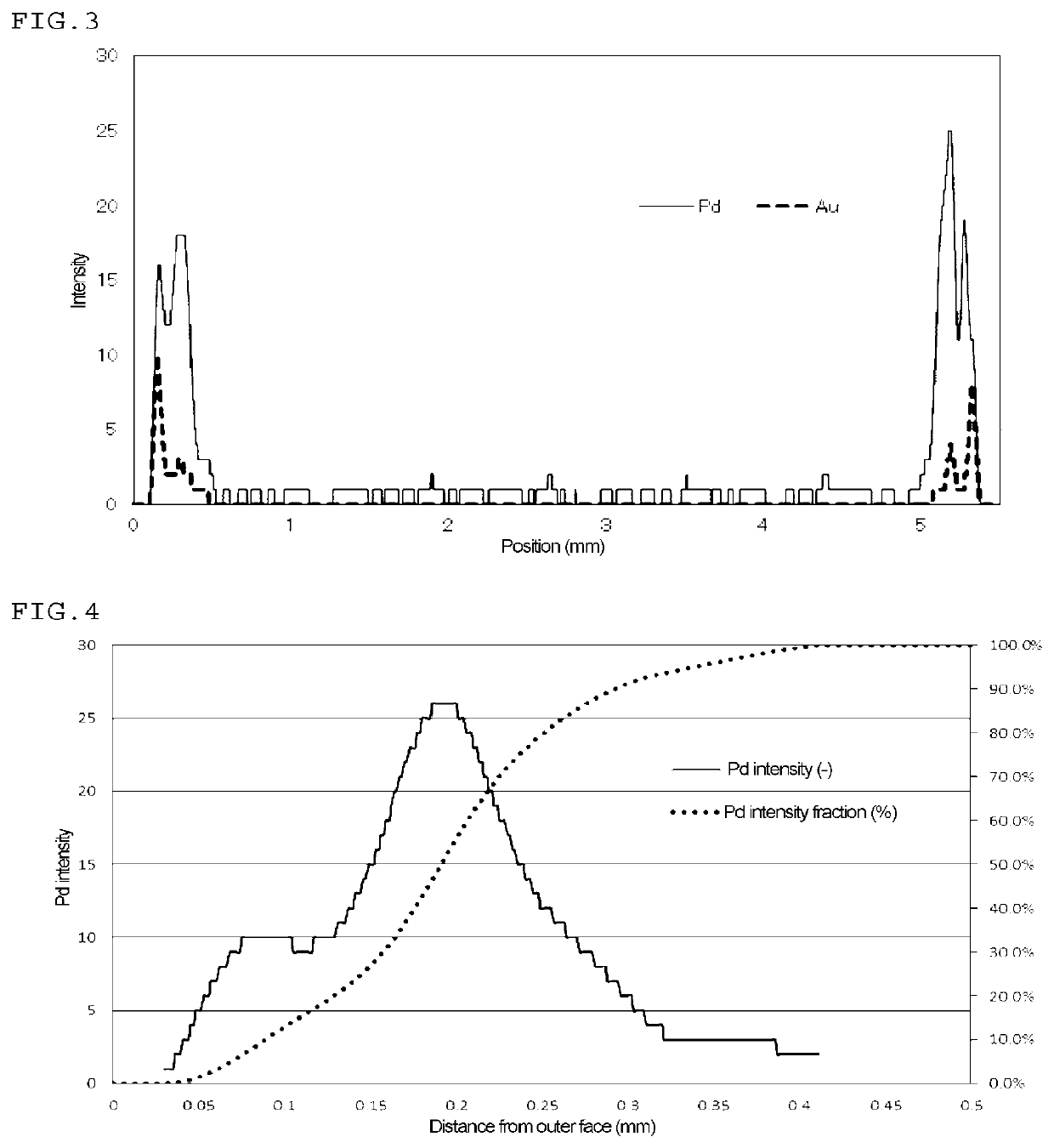

Method for producing palladium-gold loaded catalyst for vinyl acetate synthesis

ActiveUS20200094237A1Easy to adjustImprove catalytic performanceOrganic compound preparationOrganic chemistry methodsAlkaline waterPtru catalyst

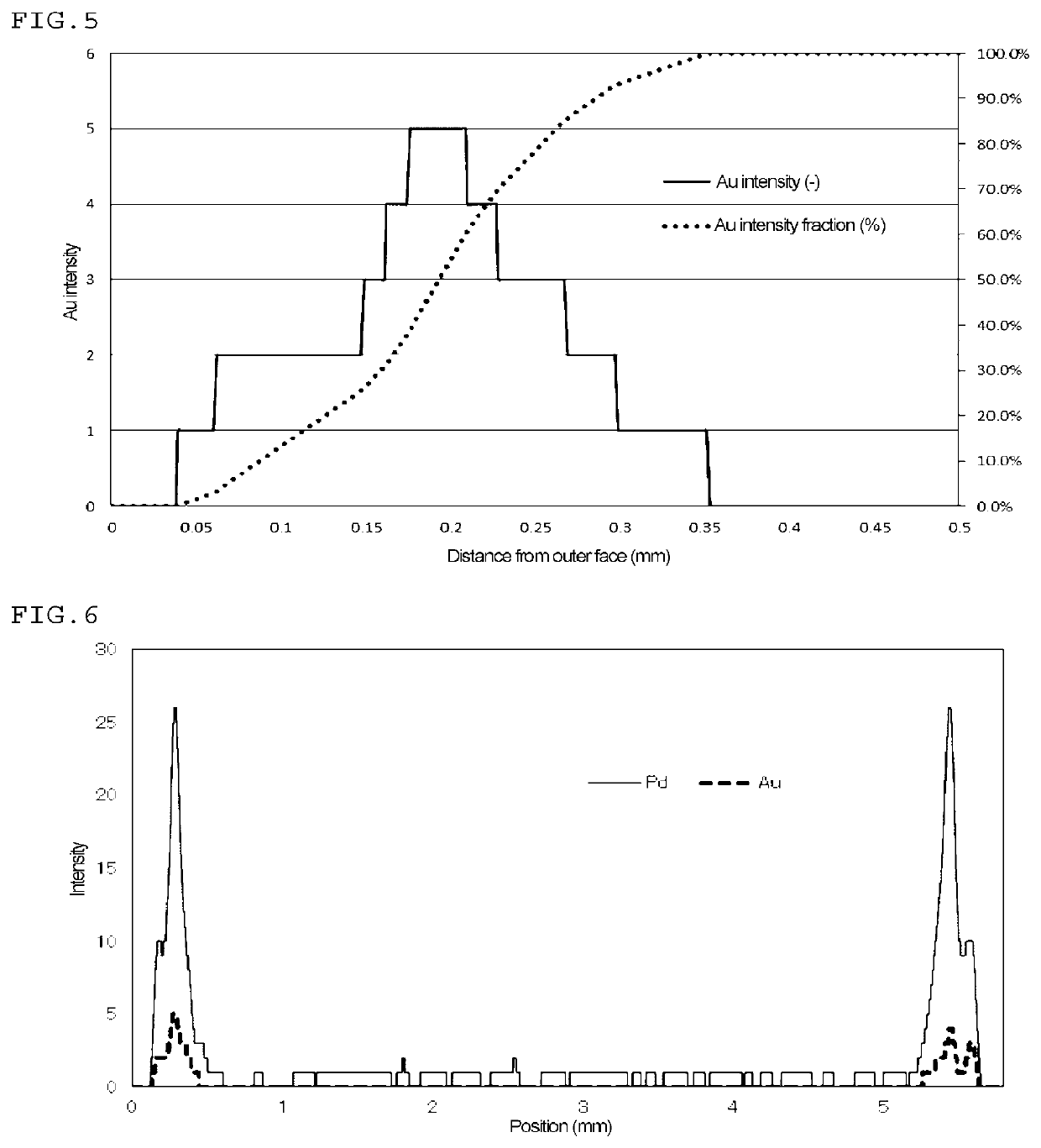

The present invention provides a technique capable of adjusting the loading positions of gold and palladium in a VAM catalyst by a method of producing a palladium-gold loaded catalyst for vinyl acetate synthesis. The method includes a step of impregnating a spherical porous molded carrier of an inorganic oxide with a mixed aqueous solution containing a palladium precursor as a catalytically active species and a gold precursor as a co-catalyst component, and subsequently impregnating the resultant spherical porous molded carrier with an aqueous alkaline solution to water-insolubilize the palladium precursor and the gold precursor in the spherical porous molded carrier to obtain a palladium-gold immobilized spherical porous molded carrier; and a subsequent step of adjusting the moisture content of the palladium-gold immobilized spherical porous molded carrier.

Owner:N E CHEMCAT

Device and method for decreasing moisture in vinyl acetate synthesis raw material acetylene gas

PendingCN109400437AIncrease profitLess side effectsHydrocarbonsAdsorption purification/separationTowerSide reaction

The invention discloses a device and method for decreasing moisture in vinyl acetate synthesis raw material acetylene gas. The device is characterized by being provided with a water scrubbing tower, an adsorption tank and a gas separating tower, the moisture contained in acetylene gas after alkali washing and impurity removal is further removed through the three unit processes of low-temperature water washing, adsorption drying and reaction liquid washing, and the moisture content in the acetylene gas is reduced to 0.01% or below. By effectively removing the moisture in the vinyl acetate production process, side reactions are decreased, the utilization rate of raw materials is improved, the production cost is reduced, and product quality is improved.

Owner:INNER MONGOLIA MENGWEI TECH CO LTD +1

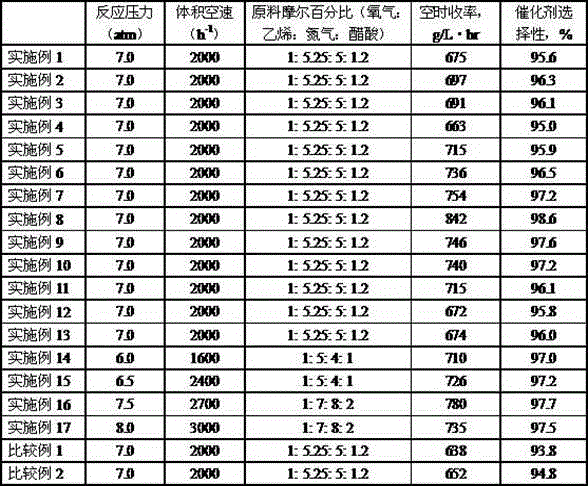

Vinyl acetate catalyst and preparation method thereof and vinyl acetate synthesis method

ActiveCN104437624AHigh space-time yieldHigh selectivityOrganic compound preparationOrganic-compounds/hydrides/coordination-complexes catalystsAlloyPotassium acetate

The invention relates to a catalyst for synthesizing vinyl acetate through an ethylene method and a preparation method of the catalyst, mainly aiming at solving problem that a catalyst in the prior art is low in space time yield and selectivity. The catalyst comprises active ingredients, an auxiliary catalyst and a carrier, wherein the active ingredients include Pd, Au and an alloy thereof, the auxiliary catalyst is potassium acetate, the content of Pd in the catalyst is 1.0-12g / L, the content of Au is 0.1-9.0g / L, and the content of the auxiliary catalyst is 10-50g / l. The catalyst is characterized in that the carrier of the catalyst is SiO2 modified by a fluorinated compound. The problem is well solved through the catalyst, and the catalyst can be applied to industrial production of vinyl acetate synthesis through the ethylene method.

Owner:CHINA PETROLEUM & CHEM CORP +1

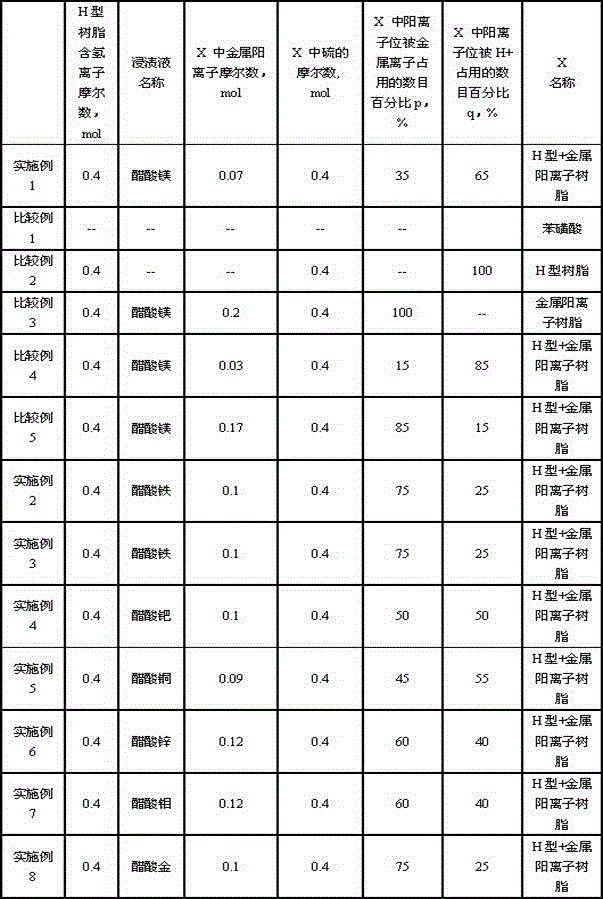

Diethylene acetate method vinyl acetate catalyst and vinyl acetate synthesis method

ActiveCN104549501BOrganic compound preparationOrganic-compounds/hydrides/coordination-complexes catalystsAlkaline earth metalSynthesis methods

The invention relates to an ethylidene diacetate method vinyl acetate catalyst and a vinyl acetate synthesis method, which are mainly used for solving the problems of low ethylidene diacetate conversion rate and poor vinyl acetate selectivity in the prior part. The problems are well solved through the adoption of the technical scheme that the catalyst is cation exchange resin which contains H+ and metal ions, wherein the metal ions are selected from at least one of alkaline-earth metal ions and transition metal ions, the metal ions accounts for a percentage p (20%-80%) of cation sites in the cation exchange resin, and H+ accounts for a percentage q (1 minus p) of the cation sites. The catalyst can be used in production of vinyl acetate.

Owner:CHINA PETROLEUM & CHEM CORP +1

Catalysts for Vinyl Acetate Synthesis

ActiveCN107774306BHigh selectivityReduce benzene contentOrganic compound preparationOrganic-compounds/hydrides/coordination-complexes catalystsBenzeneActivated carbon

Owner:CHINA PETROLEUM & CHEM CORP +1

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com