Method of desorbing zinc of waste catalyst for vinyl acetate synthesis

A waste catalyst and vinyl acetate technology, which is applied in chemical instruments and methods, physical/chemical process catalysts, metal/metal oxide/metal hydroxide catalysts, etc., can solve the problem of narrow application range, difficult handling, and large amount of washing liquid and other problems, to achieve the effect of easy follow-up treatment, fast heating speed and high desorption rate

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

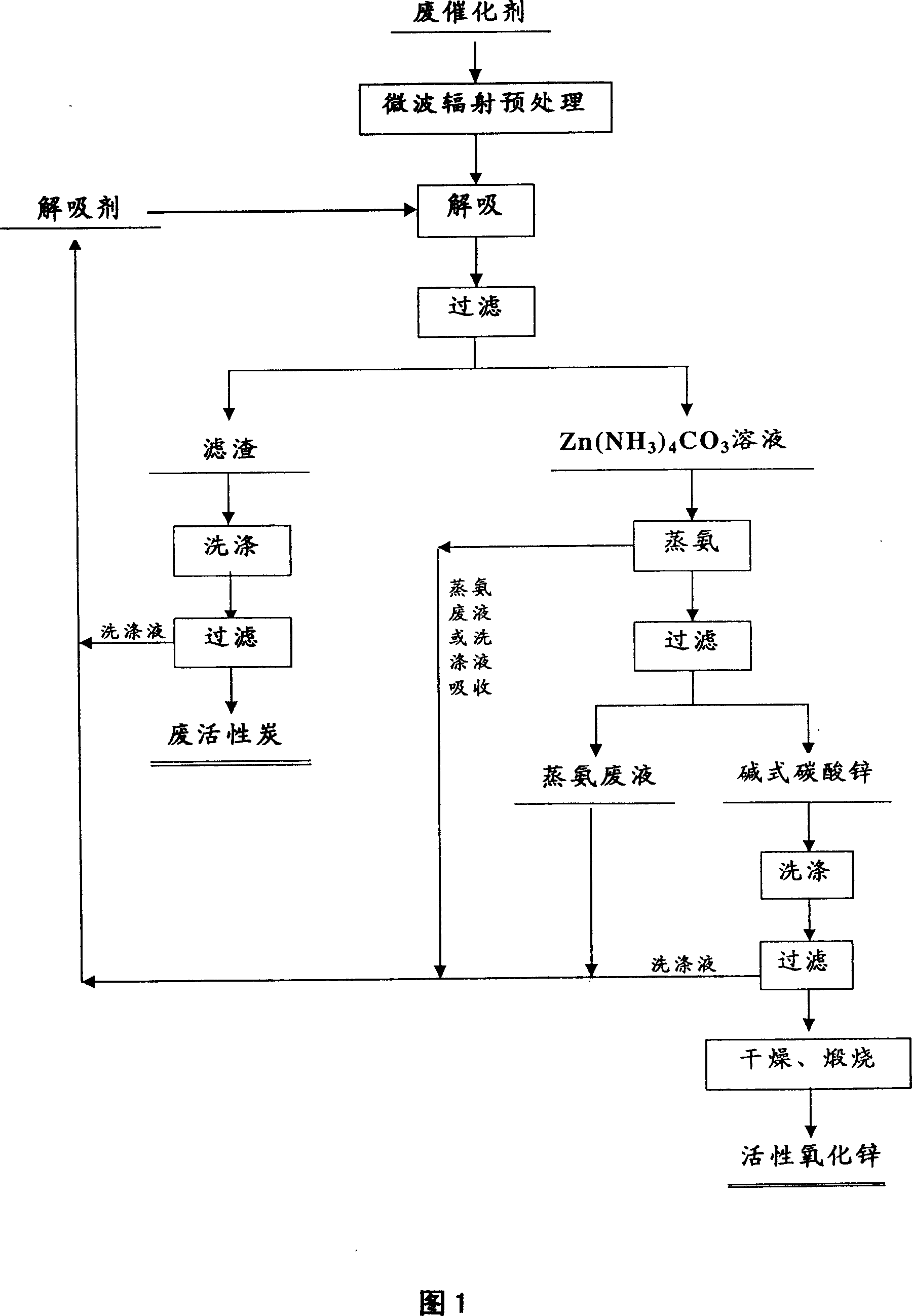

Image

Examples

Embodiment 1

[0028] The chemical composition (weight percentage) of raw material spent catalyst: C 80.71%, Zn 8.16%, Fe 0.51%, Si0.15%, Mg 0.007%, Ca 0.015%;

[0029] Weigh 500g of spent catalyst, pretreat it in a microwave oven at 2450MHz, microwave power 850W, control the temperature at 910±10°C for 40min; add 150g of ammonium bicarbonate, 400ml of 18wt% ammonia water and 600ml of water, a total of 1L of desorbent, at room temperature Desorb under normal pressure for 3 hours, wash the filter residue twice and filter, and return the filtered washing liquid to prepare a desorbent; keep the tower temperature at 90-96°C during ammonia distillation, distill ammonia for 2 hours, filter after ammonia distillation, and use the obtained ammonia distillation waste liquid The ammonia gas obtained by absorbing ammonia distillation is returned to prepare a desorbent, and the obtained basic zinc carbonate is precipitated. After washing and filtering, the obtained washing liquid is directly returned to ...

Embodiment 2

[0031] The main chemical composition (weight percentage) of raw material spent catalyst: C 84.55%, Zn 8.7 1%, Fe 0.54%, Si 0.19%, Mg 0.010%, Ca 0.013%;

[0032] Weigh 1000g of spent catalyst, pretreat it in a microwave oven at 2450MHz, microwave power 2.25kW, control the temperature at 950±10°C for 45min; add 582g of ammonium bicarbonate, 1350ml of ammonia with a concentration of 26wt% and 1650ml of water, a total of 3L of desorbent, at room temperature Desorb under normal pressure for 4 hours, wash the filter residue 3 times and filter, and return the filtered washing liquid to prepare a desorbent; keep the temperature at the top of the tower at 90-96°C during the ammonia distillation process, distill ammonia for 3 hours, filter after ammonia distillation, and obtain ammonia distillation waste liquid It is used to absorb the ammonia gas obtained by distilling ammonia and return it to prepare a desorbent. The resulting basic zinc carbonate precipitates. After washing and filter...

Embodiment 3

[0034] The main chemical composition (weight percentage) of raw material spent catalyst: C 87.13%, Zn 8.94%, Fe 0.57%, Si 0.17%, Mg 0.009%, Ca 0.017%.

[0035] Weigh 1000g of spent catalyst, pretreat it in a microwave oven at 2450MHz, power 2.25kW, control the temperature at 990±10°C for 60min, add 920g of ammonium bicarbonate, 2000ml of ammonia with a concentration of 32wt% and 2000ml of water, a total of 4L of desorbent, at room temperature Desorb under pressure for 5 hours, wash the filter residue 5 times and filter, and return the filtered washing liquid to prepare a desorbent. During the ammonia distillation process, keep the tower temperature at 90-96°C, distill ammonia for 4 hours, filter after ammonia distillation, and return the obtained ammonia distillation waste liquid directly to Prepare a desorbent, the obtained basic zinc carbonate precipitates, wash and filter, and the washing liquid is used to absorb the ammonia gas obtained by distilling ammonia and then return...

PUM

| Property | Measurement | Unit |

|---|---|---|

| iodine adsorption value | aaaaa | aaaaa |

| recovery rate | aaaaa | aaaaa |

| recovery rate | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com