Vinyl acetate production method

A technology of vinyl acetate and ethylene, which is applied in chemical instruments and methods, separation/purification of carboxylate, preparation of carboxylate, etc. It can solve the problems of large cooling water consumption, complicated operation, and consumption of ion-free water.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

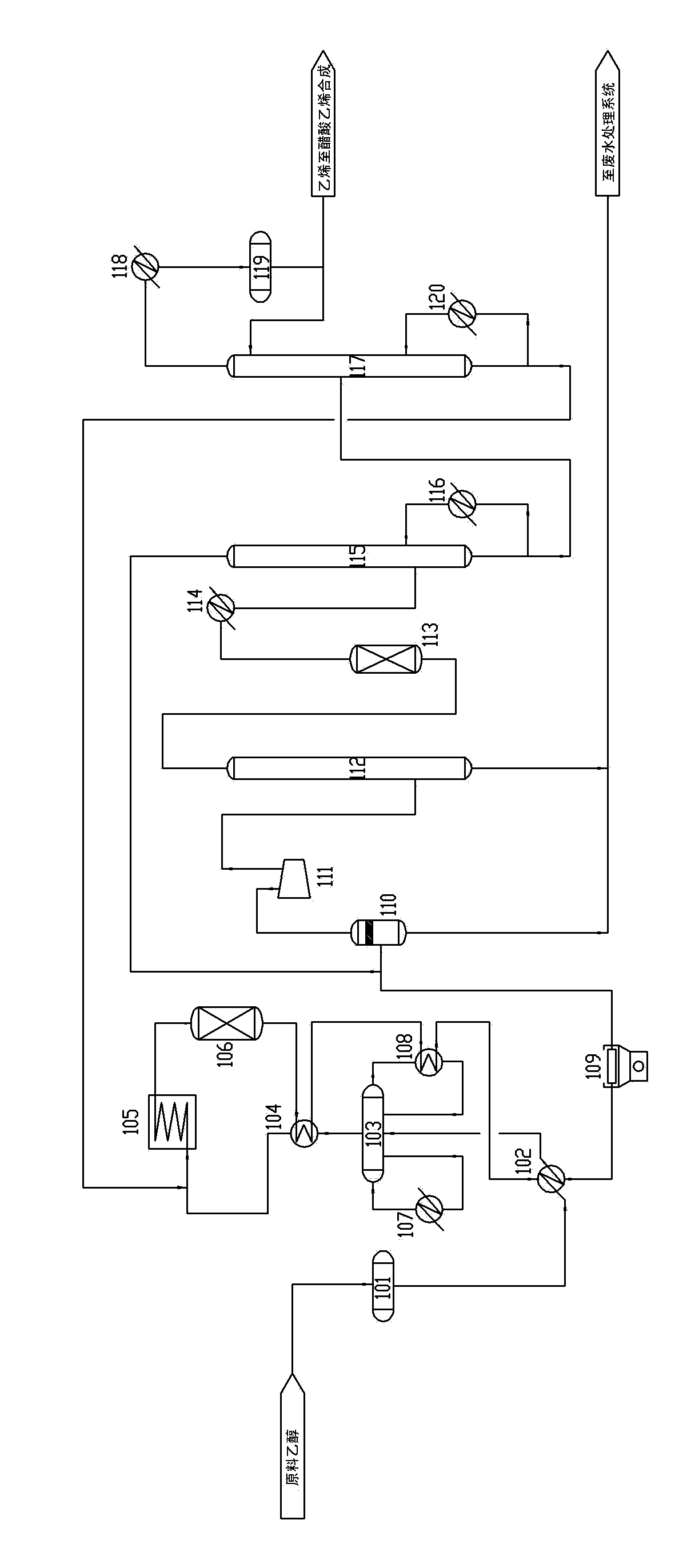

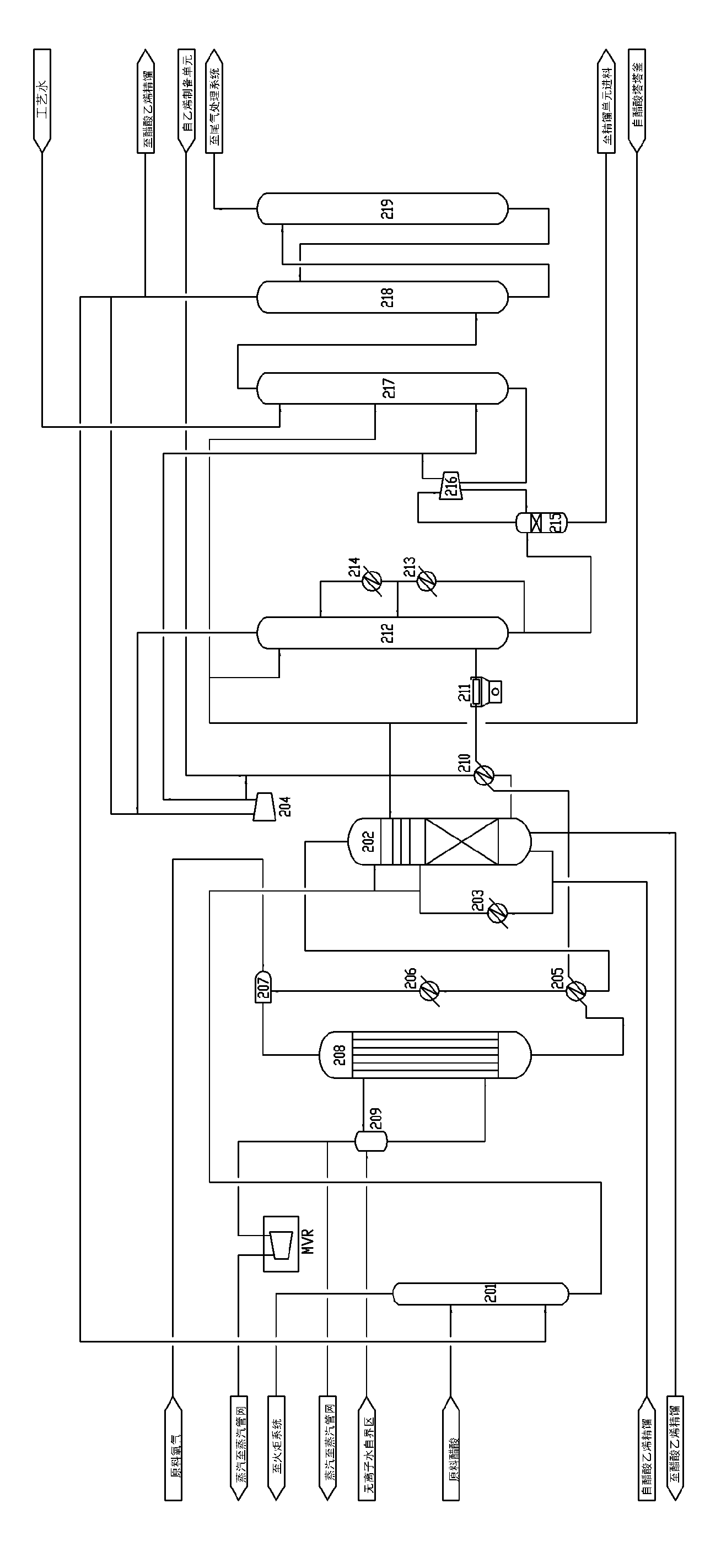

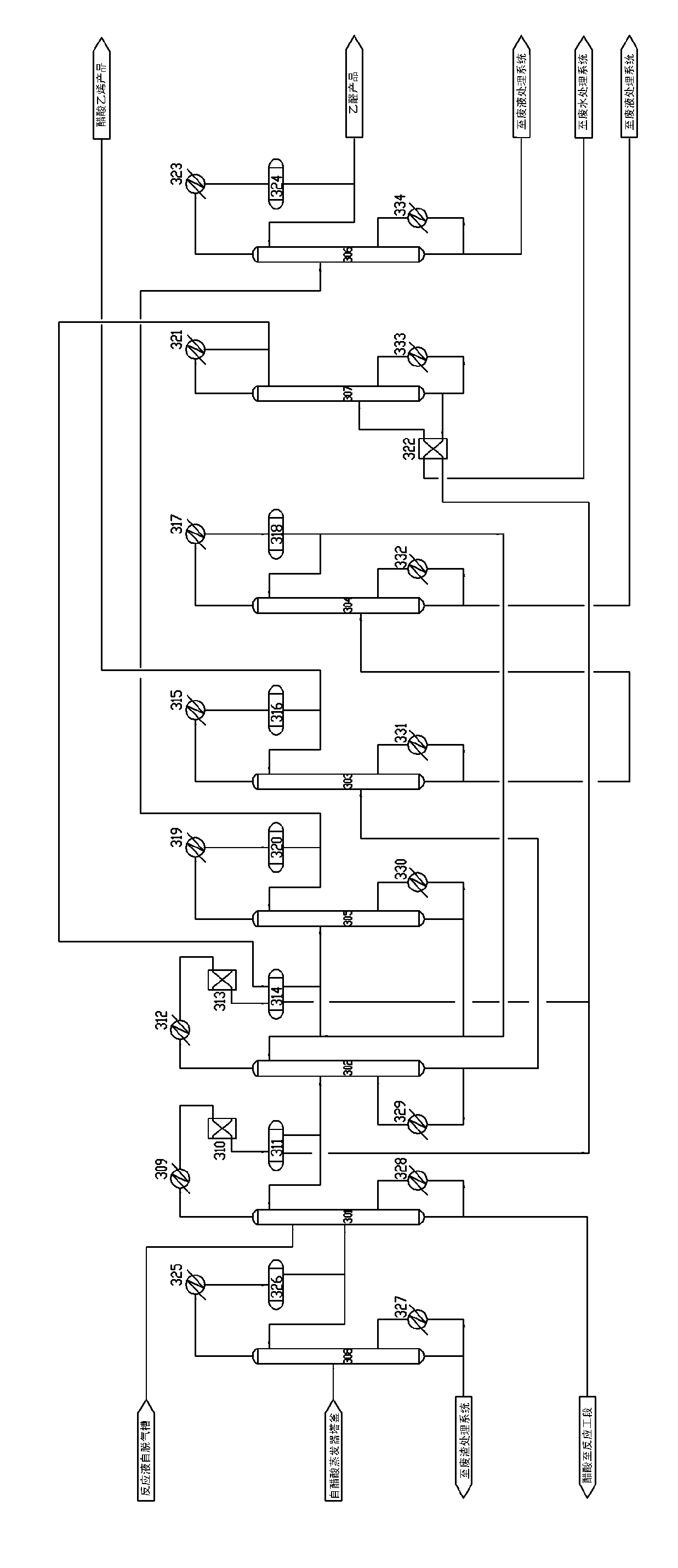

[0054] The ethylene-based vinyl acetate production method of the present invention mainly includes an ethylene preparation section (optional), a vinyl acetate synthesis section and a vinyl acetate rectification section. In the following, the above paragraphs will be described with reference to the accompanying drawings.

[0055] 1. Ethylene preparation section

[0056] The ethylene production section includes ethylene synthesis system and ethylene refining system. The raw material ethanol is sent from the raw material tank area to the ethanol tank 101, and after being preheated by the ethanol preheater 102, it enters the ethanol evaporation tank 103, and the ethanol after being overheated by the heater 104 enters the heating furnace 105, and is sent to the reactor 106 after being heated by the heating furnace . After multi-stage cooling, the reaction product is sent to the ethylene condenser 109 for further condensation. The ethylene condenser adopts the method of air conde...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com