Shell side structure and shell and tube vinyl acetate synthesis reactor with same

A synthesis reactor and vinyl acetate technology, applied in the direction of carboxylate preparation, chemical instruments and methods, chemical/physical processes, etc., can solve the problem of rising impurity content of crude vinyl acetate, inadaptability to changes in pressure, and removal of heat from the reactor Poor effect and other problems, to achieve the effect of improving heat removal effect, reducing flow resistance, and high heat removal efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

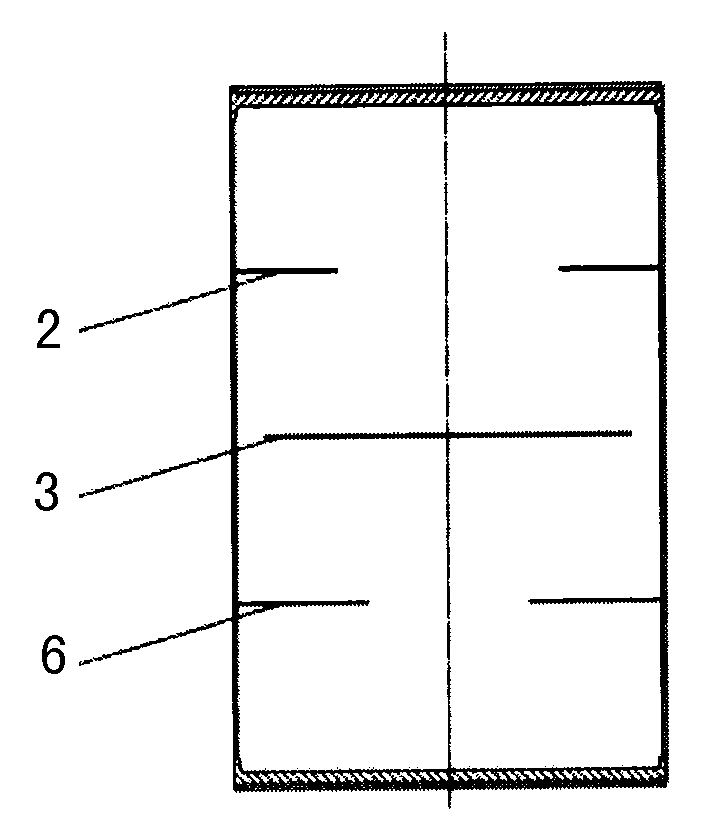

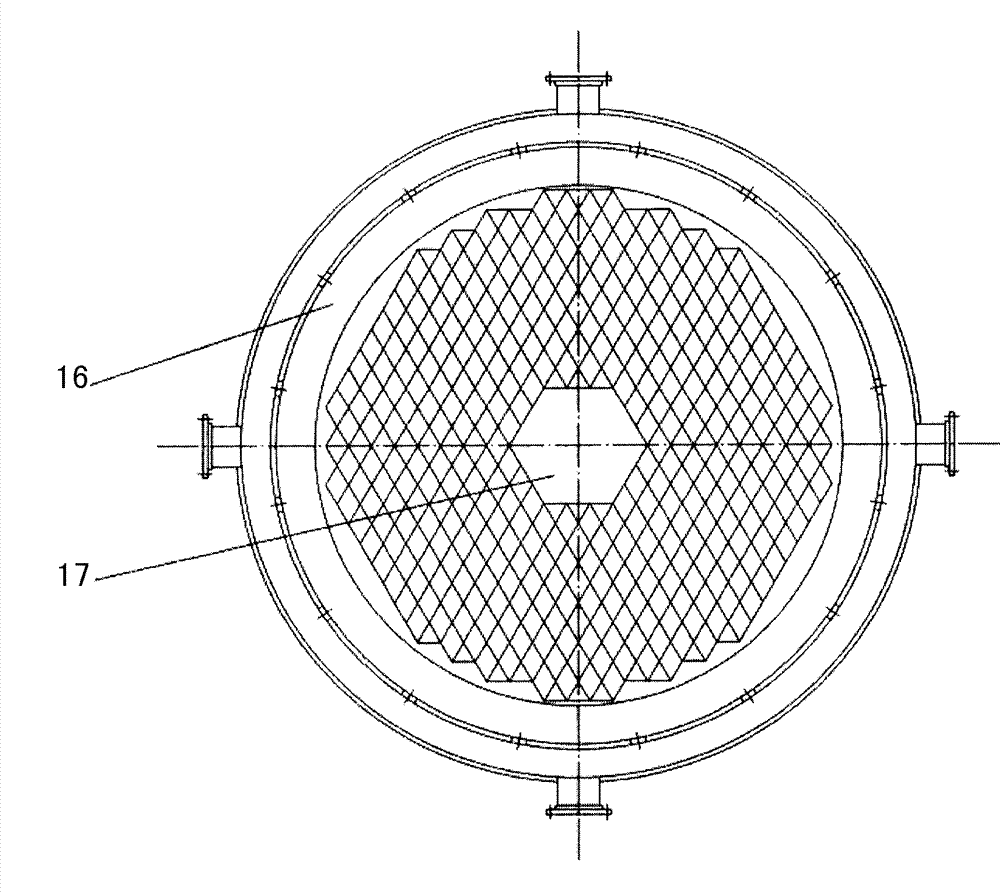

[0034] For the tubular vinyl acetate synthesis reactor, continuous improvement of the reactor structure to increase the heat removal efficiency of the reactor and reduce the temperature difference in the radial direction of the reactor is the goal that those skilled in the art have been pursuing. Among them, the setting of the annular distributor, the way of pipe layout and the way of baffles are the key to realize the uniform flow of the heat removal medium in the shell side of the tubular fixed-bed reactor. In the following preferred embodiments, the structures of these three aspects are rationally designed to achieve uniform temperature distribution in the reactor.

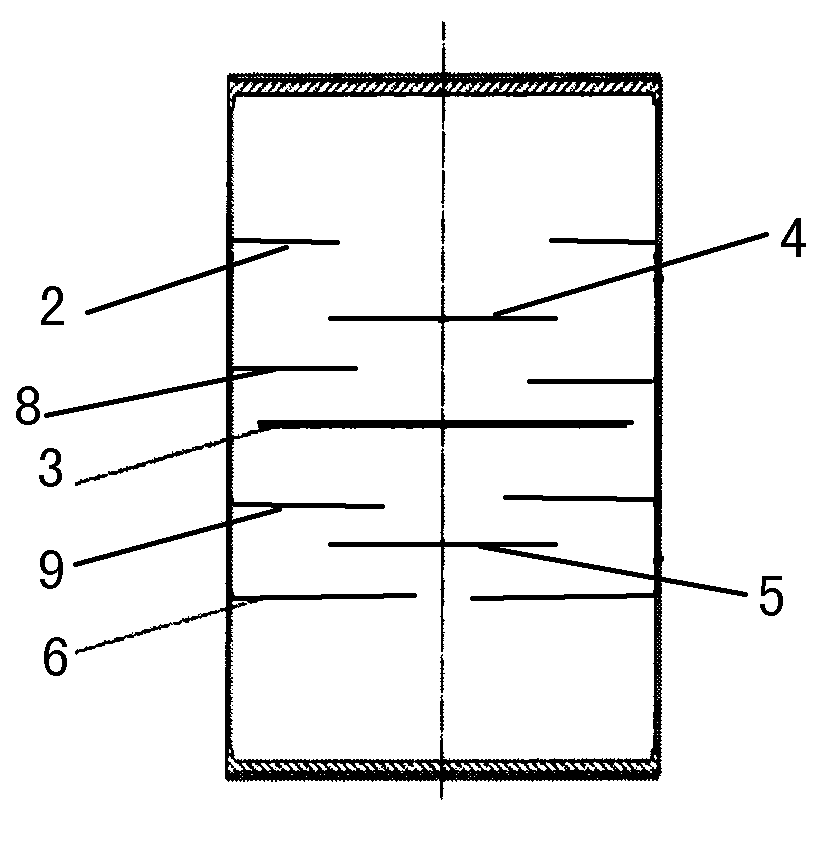

[0035] figure 1 In order to adopt the new shell-side structure according to the first embodiment of the present invention, the tube-and-tube fixed-bed reactor 18 using water-steam as the heat removal medium along the image 3 A schematic general longitudinal sectional view of section line A-A is shown. Such ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com