Catalyst for acetylene method vinyl acetate synthesis

A vinyl acetate and catalyst technology, applied in the field of acetylene vapor phase vinyl acetate catalyst, to achieve the effect of improving catalyst activity and reducing benzene content

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

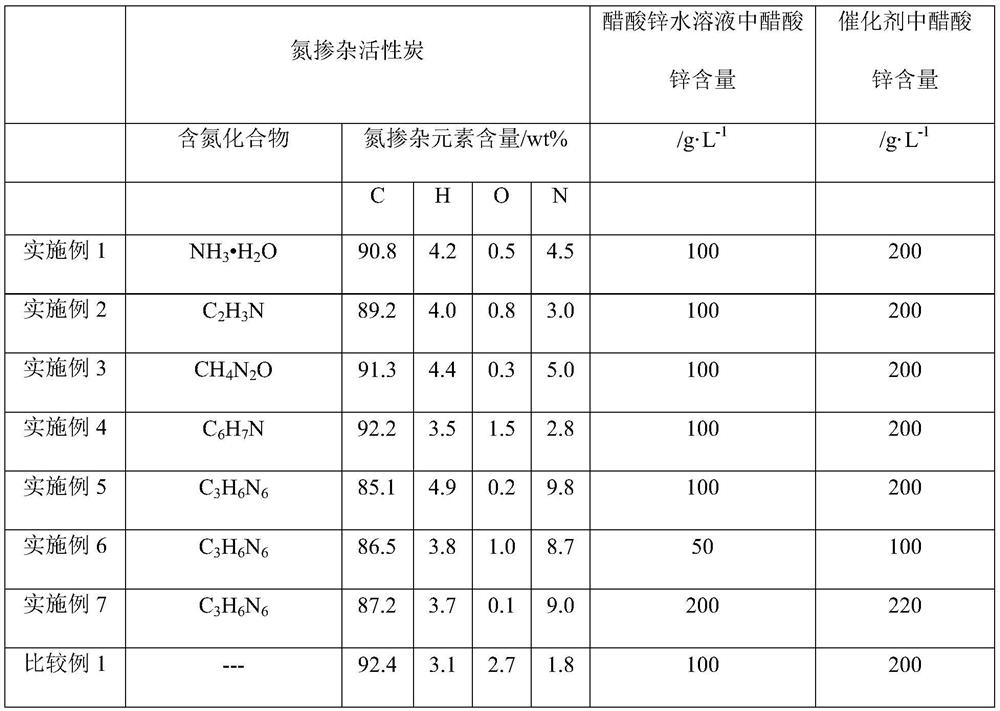

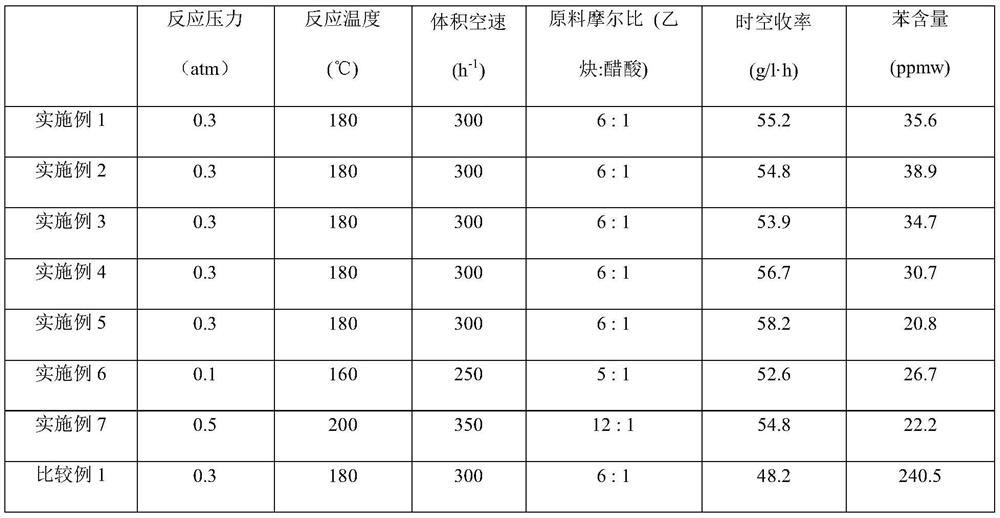

Examples

Embodiment 1

[0041] (1) Nitrogen dopant carbon preparation

[0042] a) impregnation: 100ml coconut coconut activated carbon AC is placed in 100 ml of ammonia water (NH 3 · H 2 O) Aqueous solution (100 g / l) was immersed in 60 ° C for 3 h, and at room temperature at room temperature for 8 h, filtration washed to neutral, and the AC-1a was obtained after vacuum.

[0043] b) Roast: Place 100 ml of AC-1A in a tube atmosphere, in N 2 Under the atmosphere, the program was warmed to 600 ° C (the temperature rate of 10 ° C / min, N 2 After 30 ml / min), the constant temperature was 1 h, naturally cooled to room temperature, gave a nitrogen doped activated carbon AC-1A;

[0044] (2) Preparation of catalyst

[0045] a) formulation of impregnation liquid: 20.0 g of zinc acetate (molecular formula: Zn (CH) 3 COO) 2 Dissolved in deionized water, using acetic acid to adjust its pH of 4.85 to obtain 200 ml of impregnation liquid, wherein the zinc acetate content is 100 g / L;

[0046] b) Infiltration of the...

Embodiment 2

[0061] (1) Nitrogen dopant carbon preparation

[0062] a) impregnation: 100ml coconut cocktable activated carbon AC in 100 mL acetonitrile (C 2 Hide 3 N) In aqueous solution (100 g / l), the reflux treatment was impregnated at 60 ° C for 3 h, and at room temperature was stirred at room temperature, the washed washed to neutral, and the AC-1A was obtained after vacuum.

[0063] b) Roast: Place 100 ml of AC-1A in a tube atmosphere, in N 2 Under the atmosphere, the program was warmed to 600 ° C (the temperature rate of 10 ° C / min, N 2 After 30 ml / min), the constant temperature was 1 h, naturally cooled to room temperature, gave a nitrogen doped activated carbon AC-1A;

[0064] (2) Preparation of catalyst

[0065] a) formulation of impregnation liquid: 20.0 g of zinc acetate (molecular formula: Zn (CH) 3 COO) 2 Dissolved in deionized water, using acetic acid to adjust its pH of 4.85 to obtain 200 ml of impregnation liquid, wherein the zinc acetate content is 100 g / L;

[0066] b)...

Embodiment 3

[0081] (1) Nitrogen dopant carbon preparation

[0082] a) impregnation: 100ml coconut cushion activated carbon AC is placed in 100 ml urea (CH 4 N 2 O) Aqueous solution (100 g / l) was immersed in 60 ° C for 3 h, and at room temperature at room temperature for 8 h, filtration washed to neutral, and the AC-1a was obtained after vacuum.

[0083] b) Roast: Place 100 ml of AC-1A in a tube atmosphere, in N 2 Under the atmosphere, the program was warmed to 600 ° C (the temperature rate of 10 ° C / min, N 2 After 30 ml / min), the constant temperature was 1 h, naturally cooled to room temperature, gave a nitrogen doped activated carbon AC-1A;

[0084] (2) Preparation of catalyst

[0085] a) formulation of impregnation liquid: 20.0 g of zinc acetate (molecular formula: Zn (CH) 3 COO) 2 Dissolved in deionized water, using acetic acid to adjust its pH of 4.85 to obtain 200 ml of impregnation liquid, wherein the zinc acetate content is 100 g / L;

[0086] b) Infiltration of the vector: Nitro...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com