Catalyst for vinyl acetate synthesis by acetylene method and preparation method thereof

A vinyl acetate and catalyst technology, which is applied in the field of acetylene gas phase vinyl acetate catalyst, can solve the problems of low by-product benzene content, high by-product benzene content, high by-product, etc., and achieve the effect of improving catalyst selectivity and reducing benzene content

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

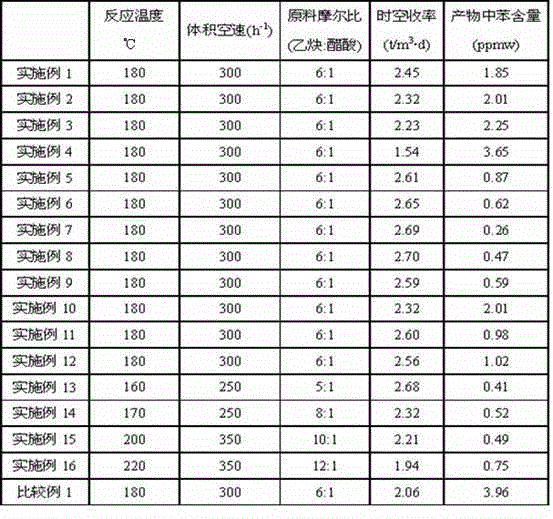

Examples

Embodiment 1

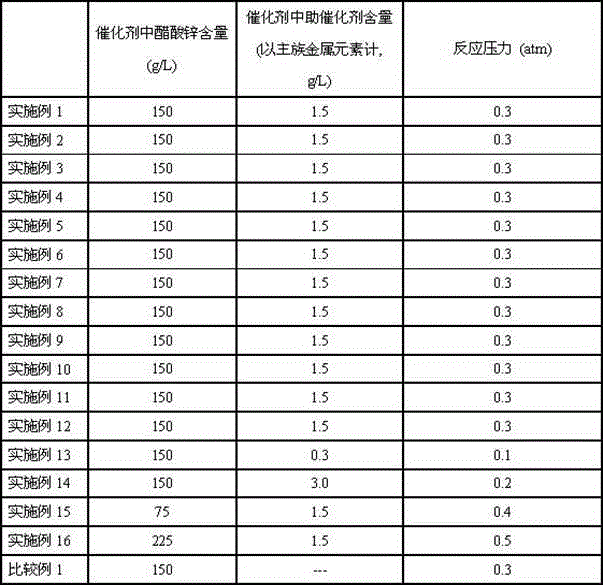

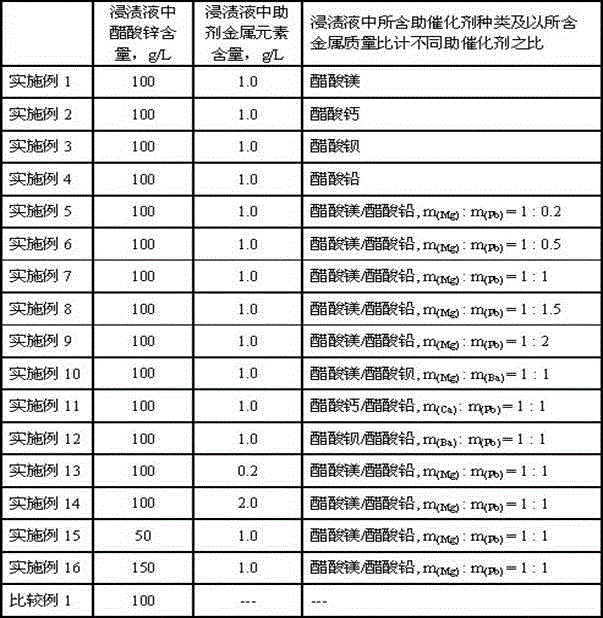

[0027] (1) Catalyst preparation

[0028] (a) Preparation of impregnation solution: weigh 7.44 ml of magnesium acetate solution (molecular formula: Mg(CH 3 COO) 2 , concentration: 1 mol / L) and 18.0 g zinc acetate (molecular formula: Zn(CH 3 COO) 2 ) solid at 60 o Dissolve C in water to prepare 180 ml of aqueous solution, adjust the pH value to 4.85 with acetic acid to obtain an impregnation solution; wherein the content of zinc acetate is 100 g / L, and the content of Mg element is 1.0 g / L;

[0029] (b) Impregnation of the carrier: Weigh 120 ml of coal-based columnar carbon (bulk density: 0.35 g / ml, BET specific surface: 1200 cm 2 / g, total pore volume: 0.7 cm 3 / g); add to the above impregnation solution, and impregnate at 60 °C for 4 hr;

[0030] (c) Drying: Dry the catalyst at 105° C. for 4 hrs in a blast drying oven to obtain the catalyst.

[0031] The main preparation conditions of the catalyst are listed in Table 1, and the physical data of the catalyst are listed in...

Embodiment 2

[0042] (1) Catalyst preparation

[0043] (a) Preparation of impregnation solution: weigh 0.71 g of calcium acetate solid (molecular formula: Ca(CH 3 COO) 2 ) and 18.0 g zinc acetate (molecular formula: Zn(CH 3 COO) 2 ) solid at 60 o Dissolve C in water to prepare 180 ml of aqueous solution, adjust the pH value to 4.85 with acetic acid to obtain an impregnating solution; the content of zinc acetate is 100 g / L, and the content of Ca element is 1.0 g / L;

[0044] (b) Impregnation of the carrier: Weigh 120 ml of coal-based columnar carbon (bulk density: 0.35 g / ml, BET specific surface: 1200 cm 2 / g, total pore volume: 0.7 cm 3 / g); add to the above impregnation solution, and impregnate at 60 °C for 4 hr;

[0045] (c) Drying: Dry the catalyst at 105° C. for 4 hrs in a blast drying oven to obtain the catalyst.

[0046] The main preparation conditions of the catalyst are listed in Table 1, and the physical data of the catalyst are listed in Table 2.

[0047] (2) Catalyst perfo...

Embodiment 3

[0050] (1) Catalyst preparation

[0051] (a) Preparation of impregnation solution: weigh 0.33 g of barium acetate solid (molecular formula: Ba(CH 3 COO) 2 ) and 18.0 g zinc acetate (molecular formula: Zn(CH 3 COO) 2 ) solid at 60 o Dissolve C in water to prepare 180 ml of aqueous solution, adjust the pH value to 4.85 with acetic acid to obtain an impregnating solution; wherein the content of zinc acetate is 100 g / L, and the content of Ba element is 1.0 g / L;

[0052] (b) Impregnation of the carrier: Weigh 120 ml of coal-based columnar carbon (bulk density: 0.35 g / ml, BET specific surface: 1200 cm 2 / g, total pore volume: 0.7 cm 3 / g); add to the above impregnation solution, and impregnate at 60 °C for 4 hr;

[0053] (c) Drying: Dry the catalyst at 105° C. for 4 hrs in a blast drying oven to obtain the catalyst.

[0054] The main preparation conditions of the catalyst are listed in Table 1, and the physical data of the catalyst are listed in Table 2.

[0055] (2) Catalys...

PUM

| Property | Measurement | Unit |

|---|---|---|

| specific surface area | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com