Catalyst for Synthesis of Vinyl Acetate by Acetylene Process

A vinyl acetate and catalyst technology, which is applied in the field of acetylene gas phase vinyl acetate catalyst, can solve the problems of corrosiveness, unspecified catalyst activity data, and restrictions on the promotion of catalysts, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

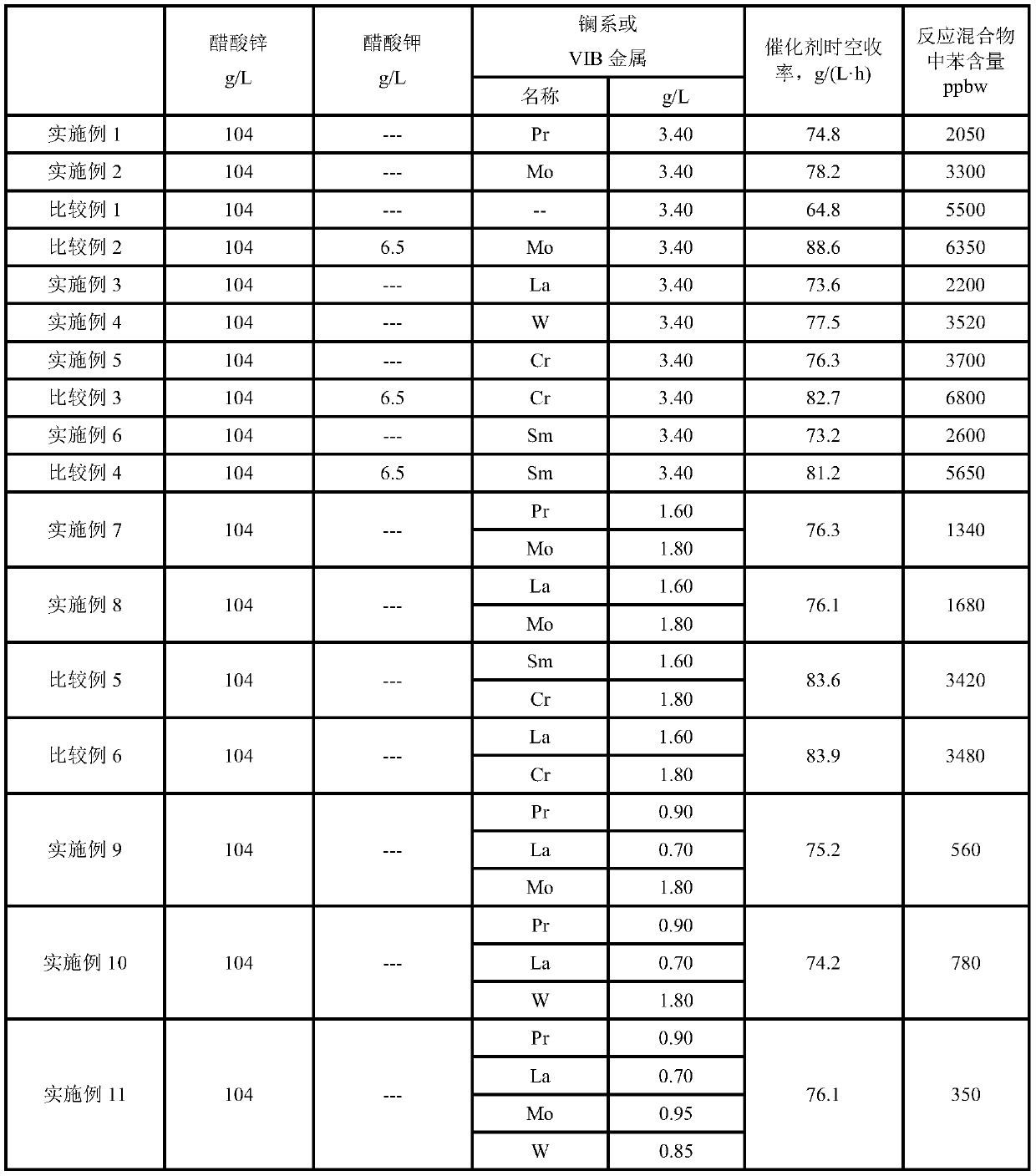

Examples

Embodiment 1

[0036] The preparation of catalyst: 104g zinc acetate (Zn(OAc) 2 ), praseodymium acetate (Pr(OAc) containing 3.40g Pr 3 ·5H 2 O) fully mix and dissolve in aqueous acetic acid solution to obtain 350ml of impregnating solution with a pH of 4.8, 1L of 3mm in diameter, 2cm in length, and 0.80cm in pore volume 3 / g, the specific surface area is 1200m 2 / g columnar coal-based activated carbon carrier was impregnated in the above impregnating solution, left to stand for 3 hours and dried at 110°C to obtain the catalyst. The zinc acetate content of this catalyst measured by ICP is 104g / L, and the Pr content is 3.40g / L.

[0037] The synthesis of vinyl acetate: 30ml catalyst is packed in the miniature fixed-bed reactor, with N 2 After leak test, use N 2 Fully purge the system, after the system heats up, turn off the N 2 , cut into acetylene in turn, turn on the acetic acid pump, control the reaction temperature to 178°C, and the reaction pressure to 0.25atm; raw material volume sp...

Embodiment 2

[0041] The preparation of catalyst: 104g zinc acetate (Zn(OAc) 2 ), ammonium molybdate ((NH 4 ) 6 Mo 7 o 24 .4H 2 O) fully mix and dissolve in aqueous acetic acid solution to obtain 350ml of impregnating solution with a pH of 4.8, 1L of 3mm in diameter, 2cm in length, and 0.80cm in pore volume 3 / g, the specific surface area is 1200m 2 / g columnar coal-based activated carbon carrier was impregnated in the above impregnating solution, left to stand for 3 hours and dried at 110°C to obtain the catalyst. The Zn content of the catalyst measured by ICP is 104g / L, and the Mo content is 3.40g / L.

[0042] The synthesis of vinyl acetate: 30ml catalyst is packed in the miniature fixed-bed reactor, with N 2 After leak test, use N 2 Fully purge the system, after the system heats up, turn off the N 2 , cut into acetylene in turn, turn on the acetic acid pump, control the reaction temperature to 178°C, and the reaction pressure to 0.25atm; raw material volume space velocity: 300h ...

Embodiment 3

[0057] The preparation of catalyst: 104g zinc acetate (Zn(OAc) 2 ), lanthanum acetate (La(OAc) containing 3.40g La 3 ·5H 2 O) fully mix and dissolve in aqueous acetic acid solution to obtain 350ml of impregnating solution with a pH of 4.8, 1L of 3mm in diameter, 2cm in length, and 0.80cm in pore volume 3 / g, the specific surface area is 1200m 2 / g columnar coal-based activated carbon carrier was impregnated in the above impregnating solution, left to stand for 3 hours and dried at 110°C to obtain the catalyst. The zinc acetate content of this catalyst measured by ICP is 104g / L, and the La content is 3.40g / L.

[0058] The synthesis of vinyl acetate: 30ml catalyst is packed in the miniature fixed-bed reactor, with N 2After leak test, use N 2 Fully purge the system, after the system heats up, turn off the N 2 , cut into acetylene in turn, turn on the acetic acid pump, control the reaction temperature to 178°C, and the reaction pressure to 0.25atm; raw material volume space ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com