Aromatization catalyst and preparation method, regeneration method and aromatization method thereof

A catalyst and aromatization technology, which is applied in the field of aromatization catalyst and its preparation, can solve the problem of selective conversion of olefins to aromatics with liquid yield, short service life of aromatization catalyst, and poor adaptability to industrial scale-up And other issues

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

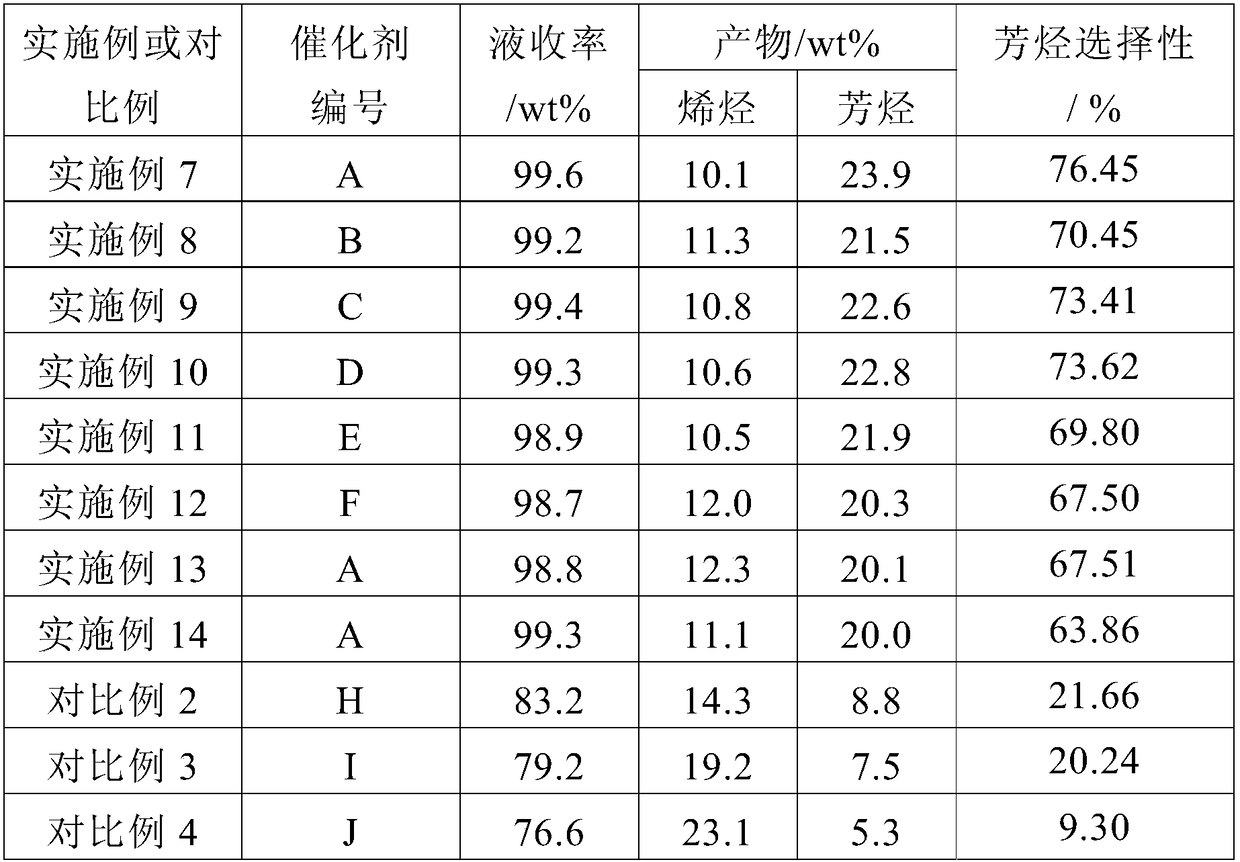

Examples

Embodiment 1

[0060] This embodiment provides a method for preparing an aromatization catalyst, which includes the following steps in sequence:

[0061] 1. At room temperature, physically mix the nanoscale HZSM-5 molecular sieve with a silicon-aluminum ratio of 25 and pseudo-boehmite at a ratio of 4:1 to obtain a catalyst precursor.

[0062] 2. Use the method of constant temperature water bath to carry out ion exchange treatment on the catalyst precursor. Specifically, dissolve sodium hydroxide in deionized water, mix it with the catalyst precursor and place it in a water bath environment at 90°C for 2 hours to make the loading capacity of sodium It is about 0.2 wt%, and then dried at about 120°C for about 8 hours and fired at about 540°C for about 4 hours.

[0063] 3. Using the equal volume impregnation method, carry out the first modification treatment on the catalyst precursor treated by ion exchange, specifically dissolving ammonium dihydrogen phosphate in deionized water, and then impr...

Embodiment 2

[0067] This embodiment provides a method for preparing an aromatization catalyst, the specific steps of which are basically the same as in Example 1, the difference being:

[0068] In the process of active metal loading in step 4, the loading amount of zinc is about 8wt%.

[0069] The aromatization catalyst finally obtained in Example 2 is designated as catalyst B.

Embodiment 3

[0071] This embodiment provides a method for preparing an aromatization catalyst, comprising the following steps:

[0072] 1. At room temperature, physically mix the hydrogen-type ZSM-5 molecular sieve with a silicon-aluminum ratio of 25 and nano-scale and pseudo-boehmite at a ratio of 9:1 to obtain a catalyst precursor.

[0073] 2. Use the method of constant temperature water bath to carry out ion exchange treatment on the catalyst precursor. Specifically, dissolve sodium hydroxide in deionized water, mix it with the catalyst precursor and place it in a water bath environment at 90°C for 2 hours to make the loading capacity of sodium It is about 0.5 wt%, and then dried at about 120°C for about 8 hours and fired at about 540°C for about 4 hours.

[0074] 3. Using the equal-volume impregnation method, the first modification is carried out on the catalyst precursor treated by ion exchange, specifically dissolving ammonium dihydrogen phosphate in deionized water, and then impregn...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com