An aromatization catalyst and its preparation method, regeneration method and aromatization method

An aromatization and catalyst technology, applied in the field of aromatization catalyst and its preparation, can solve the problems of low catalytic activity, affecting the production efficiency and economic benefits of enterprises, and short service life of aromatization catalyst

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

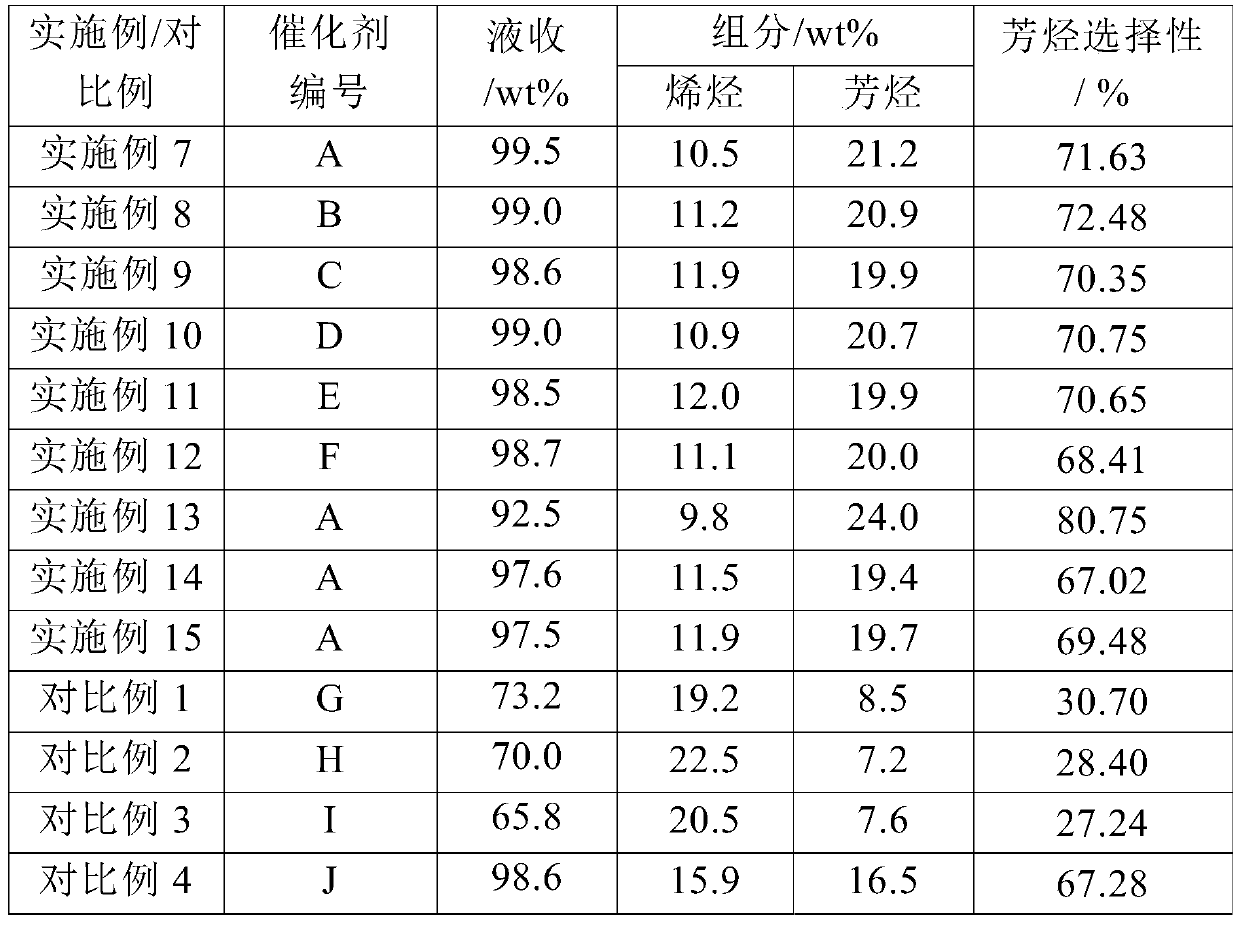

Examples

Embodiment 1

[0072] 1. Mix ethyl orthosilicate, sodium metaaluminate, tetrapropylammonium hydroxide, tetrapropylammonium hydroxide, deionized water and GPTMS according to the weight ratio of 98.4:0.24:1.2:0.12:1.24:0.05. , to obtain a gel mixture, then heat the mixture to about 70°C under normal pressure, keep stirring at a constant temperature for about 10 hours, then move it into a crystallization tank; raise the temperature to 170°C and maintain this temperature for crystallization for about 72 hours, and then Rapidly cool with ice water to quickly stop the crystallization, and then remove the obtained crystallized product from the crystallization kettle.

[0073] The crystallized product was filtered, washed with deionized water until neutral, then dried at 110°C for 12 hours, and calcined in an air atmosphere at about 540°C for 3 hours, then at about 90°C, with 0.5mol / The HCl solution of L was exchanged twice, about 2 hours each time, and finally washed, dried, and calcined at a temp...

Embodiment 2

[0080] 1. With reference to steps 1 to 4 in Example 1, the HZSM-5 molecular sieve carrier was prepared, and ion exchange treatment, first modification treatment and hydrothermal aging treatment were performed sequentially on it.

[0081] 2. Using the equal volume impregnation method, carry out active metal loading and second modification treatment on the HZSM-5 molecular sieve carrier obtained in step 1:

[0082] Configure a mixed aqueous solution of nickel nitrate and ammonium dihydrogen phosphate; use the above mixed aqueous solution to impregnate the HZSM-5 molecular sieve carrier synchronously, and control the mass ratio of the mixed aqueous solution to the HZSM-5 molecular sieve carrier to be about 0.85:1, so that the loading of nickel and phosphorus The amounts are 4wt% and 1wt%, respectively; after impregnation, the samples obtained are dried at about 120°C for about 12 hours, and then calcined at about 500°C for about 4 hours to obtain an aromatization catalyst, which i...

Embodiment 3

[0084] 1. With reference to steps 1 to 4 in the examples, the HZSM-5 molecular sieve carrier was prepared, and ion exchange treatment, first modification treatment and hydrothermal aging treatment were performed sequentially on it.

[0085] 2. Using the equal volume impregnation method, carry out active metal loading and second modification treatment on the HZSM-5 molecular sieve carrier obtained in step 1:

[0086] Prepare a mixed aqueous solution of nickel nitrate and ammonium dihydrogen phosphate, and simultaneously impregnate the HZSM-5 molecular sieve carrier, and control the mass ratio of the mixed aqueous solution to the HZSM-5 molecular sieve carrier to be about 0.85:1, so that the loadings of nickel and phosphorus are respectively 7.8wt% and 1wt%; after the impregnation, the sample obtained was dried at a temperature of about 120°C for about 12 hours, and then roasted at a temperature of about 500°C for about 4 hours; an aromatization catalyst was obtained, which was d...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com