Catalysts for the production of vinyl acetate

A vinyl acetate and catalyst technology, applied in the field of acetylene vapor phase vinyl acetate catalyst, can solve the problems of corrosion, unspecified catalyst activity data, environmental pollution, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

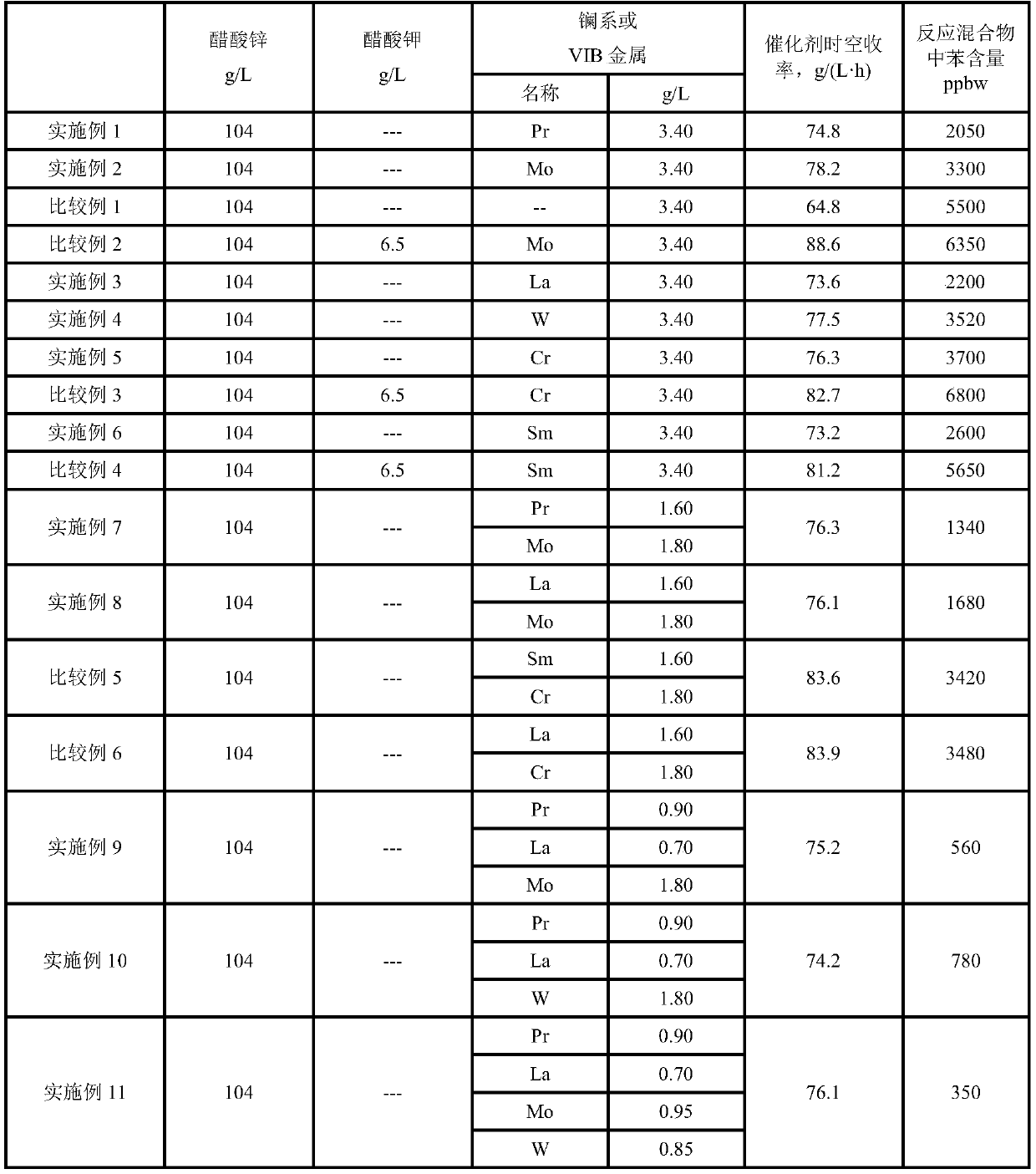

Examples

Embodiment 1

[0038] The preparation of catalyst: 104g zinc acetate (Zn(OAc) 2 ), praseodymium acetate (Pr(OAc) containing 3.40g Pr 3 ·5H 2 O) fully mix and dissolve in aqueous acetic acid solution to obtain 350ml of impregnating solution with a pH of 4.8, 1L of 3mm in diameter, 2cm in length, and 0.80cm in pore volume 3 / g, the specific surface area is 1200m 2 / g columnar coal-based activated carbon carrier was impregnated in the above impregnating solution, left to stand for 3 hours and dried at 110°C to obtain the catalyst. The zinc acetate content of this catalyst measured by ICP is 104g / L, and the Pr content is 3.40g / L.

[0039] The synthesis of vinyl acetate: 30ml catalyst is packed in the miniature fixed-bed reactor, with N 2 After leak test, use N 2 Fully purge the system, after the system heats up, turn off the N 2 , cut into acetylene in turn, turn on the acetic acid pump, control the reaction temperature to 178°C, and the reaction pressure to 0.25atm; raw material volume sp...

Embodiment 2

[0043] The preparation of catalyst: 104g zinc acetate (Zn(OAc) 2 ), ammonium molybdate ((NH 4 ) 6 Mo 7 o 24 .4H 2 O) fully mix and dissolve in aqueous acetic acid solution to obtain 350ml of impregnating solution with a pH of 4.8, 1L of 3mm in diameter, 2cm in length, and 0.80cm in pore volume 3 / g, the specific surface area is 1200m 2 / g columnar coal-based activated carbon carrier was impregnated in the above impregnating solution, left to stand for 3 hours and dried at 110°C to obtain the catalyst. The Zn content of the catalyst measured by ICP is 104g / L, and the Mo content is 3.40g / L.

[0044] The synthesis of vinyl acetate: 30ml catalyst is packed in the miniature fixed-bed reactor, with N 2 After leak test, use N 2 Fully purge the system, after the system heats up, turn off the N 2 , cut into acetylene in turn, turn on the acetic acid pump, control the reaction temperature to 178°C, and the reaction pressure to 0.25atm; raw material volume space velocity: 300h ...

Embodiment 3

[0059] The preparation of catalyst: 104g zinc acetate (Zn(OAc) 2 ), lanthanum acetate (La(OAc) containing 3.40g La 3 ·5H 2 O) fully mix and dissolve in aqueous acetic acid solution to obtain 350ml of impregnating solution with a pH of 4.8, 1L of 3mm in diameter, 2cm in length, and 0.80cm in pore volume 3 / g, the specific surface area is 1200m2 / g columnar coal-based activated carbon carrier was impregnated in the above impregnating solution, left to stand for 3 hours and dried at 110°C to obtain the catalyst. The zinc acetate content of this catalyst measured by ICP is 104g / L, and the La content is 3.40g / L.

[0060] The synthesis of vinyl acetate: 30ml catalyst is packed in the miniature fixed-bed reactor, with N 2 After leak test, use N 2 Fully purge the system, after the system heats up, turn off the N 2 , cut into acetylene in turn, turn on the acetic acid pump, control the reaction temperature to 178°C, and the reaction pressure to 0.25atm; raw material volume space v...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com