Vinyl acetate production device and method in cooperation with heat accumulating type calcium carbide production process

A vinyl acetate production process technology, applied in the field of co-production of vinyl acetate with regenerative calcium carbide production process, to achieve the effects of low power consumption, strong comprehensive product competitiveness and good economy

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment

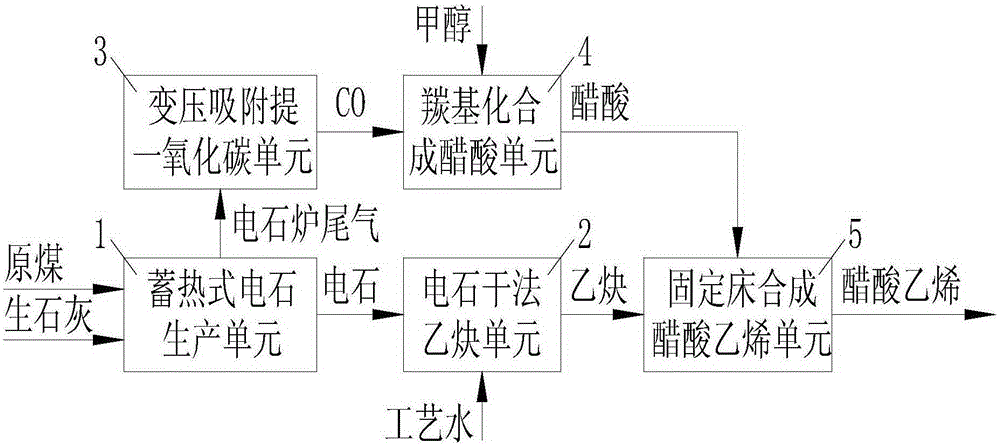

[0039] like figure 1As shown, it includes the following units: regenerative calcium carbide production unit 1, calcium carbide dry acetylene unit 2, pressure swing adsorption carbon monoxide extraction unit 3, carbonylation synthesis of acetic acid unit 4, fixed bed synthesis of vinyl acetate unit 5. in:

[0040] The regenerative calcium carbide production unit 1 includes a raw material treatment process, a rotary bed coal dry distillation process, a calcium carbide furnace process, and a dry distillation gas purification process;

[0041] The raw material processing process is a raw material processing system, the main function of which is the reception of raw coal and quicklime, as well as the crushing, grinding, batching, mixing and agglomeration of raw coal and quicklime, so as to meet the requirements of the pyrolysis rotary bed for qualified agglomeration ;

[0042] In the rotating bed coal dry distillation process, the pellets formed from the raw material treatment pr...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com