Lithium hexafluorophosphate production plant

A technology for lithium hexafluorophosphate and production equipment, which is applied in the direction of lithium hexafluorophosphate, phosphorus compounds, inorganic chemistry, etc., can solve problems such as difficult to achieve continuous, automatic production, unsatisfactory quality consistency, complicated production process, etc., to achieve simple and efficient production process, reduce Material loss and environmental pollution, the effect of excellent work performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

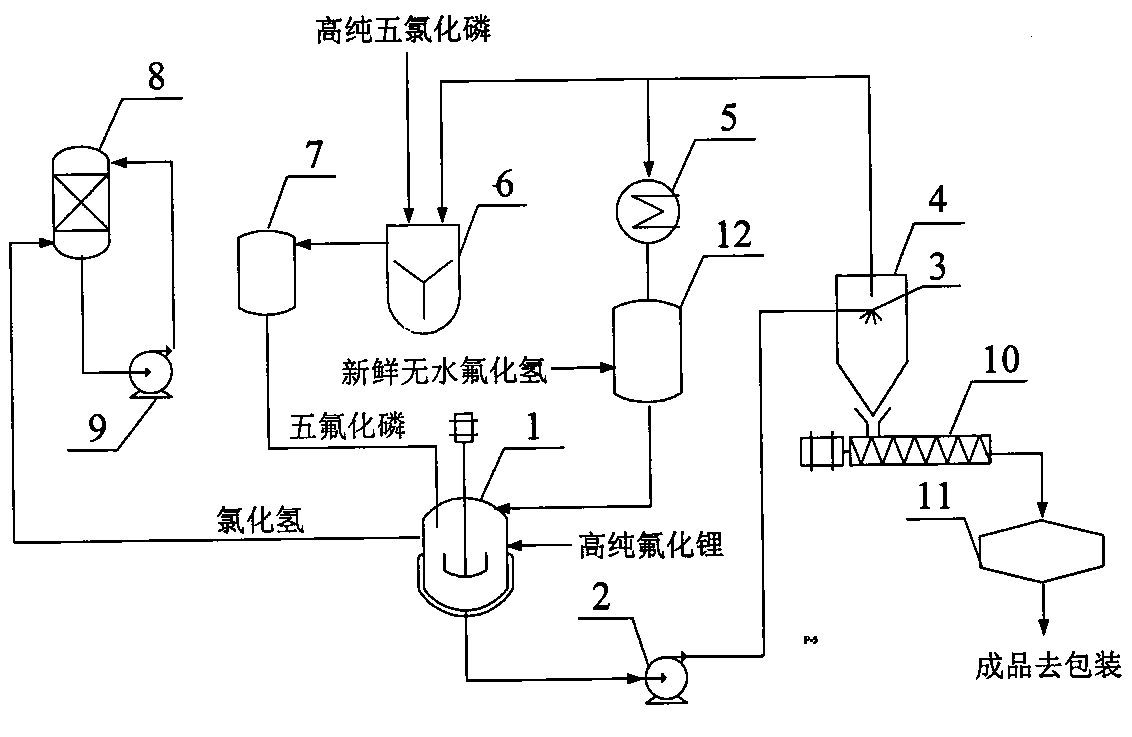

[0024] A lithium hexafluorophosphate production device, comprising a lithium hexafluorophosphate synthesis kettle 1, the lithium hexafluorophosphate synthesis kettle is connected to a material transfer pump 2 of the synthesis kettle, and the material transfer pump of the synthesis kettle is connected to the atomizing nozzle 3 in the drying tower 4 through a delivery pipe, and the tower wall of the drying tower is divided into There are multiple sections, and the temperature of the multi-section tower wall increases from top to bottom, and the temperature of each section of the tower wall remains constant. The top outlet of the drying tower is connected with the anhydrous hydrogen fluoride condenser 5 and the phosphorus pentafluoride reactor 6 through a mass flow meter; The water hydrogen fluoride condenser is connected with the anhydrous hydrogen fluoride storage tank 12, and the anhydrous hydrogen fluoride storage tank is connected with the lithium hexafluorophosphate synthesis...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com