Ball mill with four-face pyramid grinding body

A grinding body and ball mill technology, applied in grain processing and other directions, can solve problems such as low grinding efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach 1

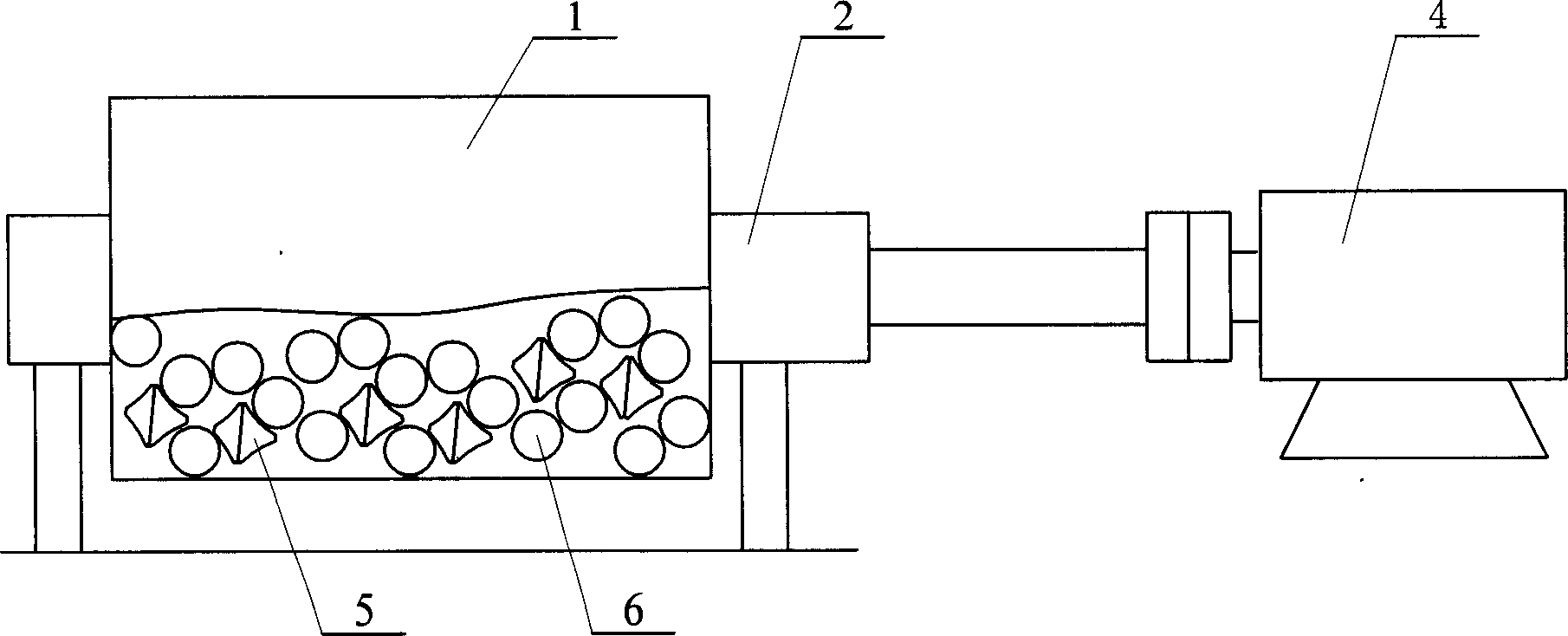

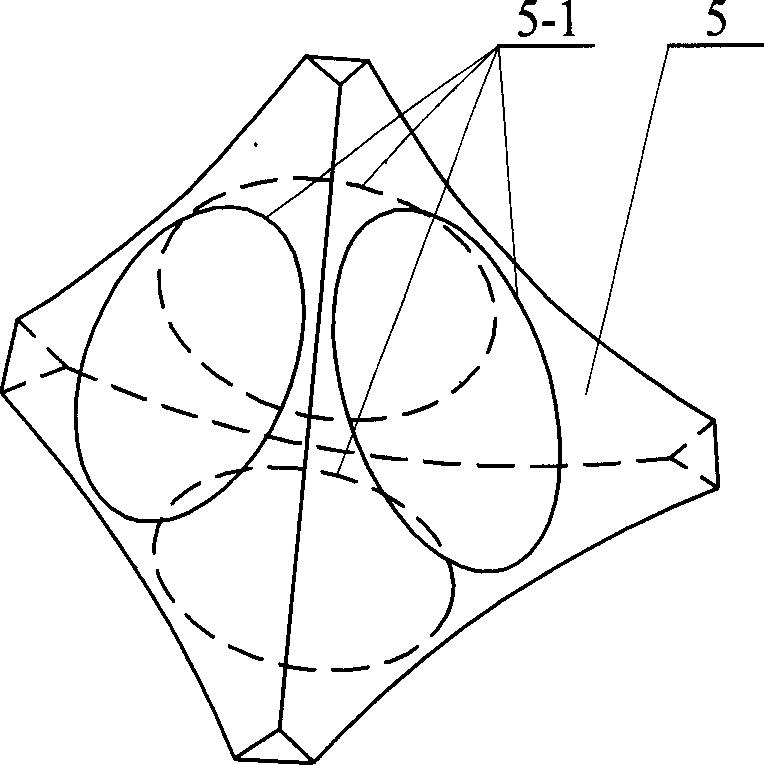

[0005] Specific embodiment one: the ball mill of this embodiment, it comprises cylinder body 1, is provided with shaft 2 on cylinder body 1, and one end of shaft 2 is connected with motor 4, and four-sided conical grinding body 5 and circle are loaded into cylinder body 1 simultaneously. shaped grinding ball 6, the ratio of the number of the four-sided conical grinding body 5 to the circular grinding ball 6 is 1:10~2:1, the shape of the four-sided conical grinding body 5 is a regular four-sided cone, and the four-sided cone The four faces of the shaped grinding body 5 are all provided with concave spherical surfaces 5-1, and the aforementioned four-sided conical grinding body 5 is made of ceramic materials. During the rotation, the circular grinding ball 6 rubs against the concave spherical surface 5-1 of the four-sided conical grinding body 5, thereby grinding the product to be ground. The product of the invention is used in conjunction with the existing round grinding balls,...

specific Embodiment approach 2

[0006] Embodiment 2: In this embodiment, the number ratio of four-sided conical grinding bodies 5 to circular grinding balls 6 is 5:3. The four-sided conical grinding body 5 is made of metal materials.

specific Embodiment approach 3

[0007] Embodiment 3: The number ratio of four-sided conical grinding bodies 5 and circular grinding balls 6 in this embodiment is 1:1.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com