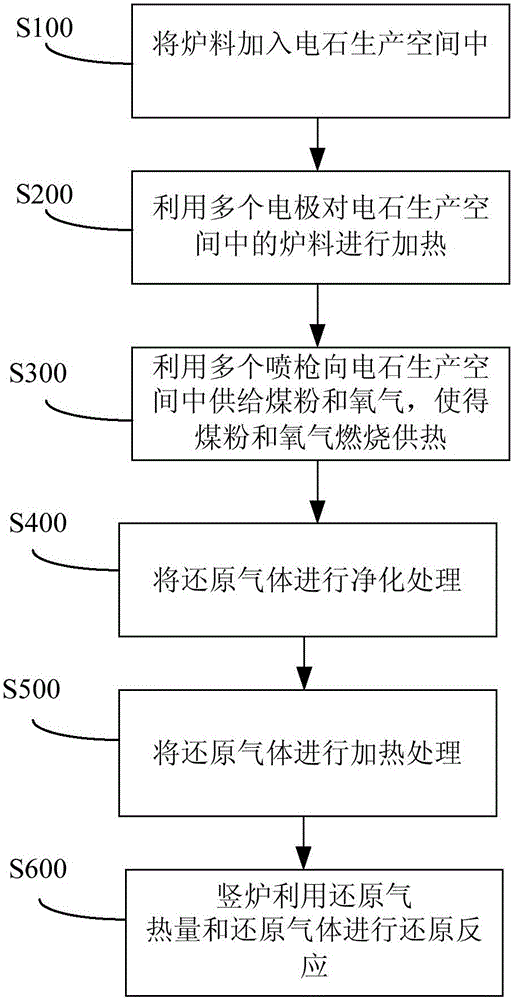

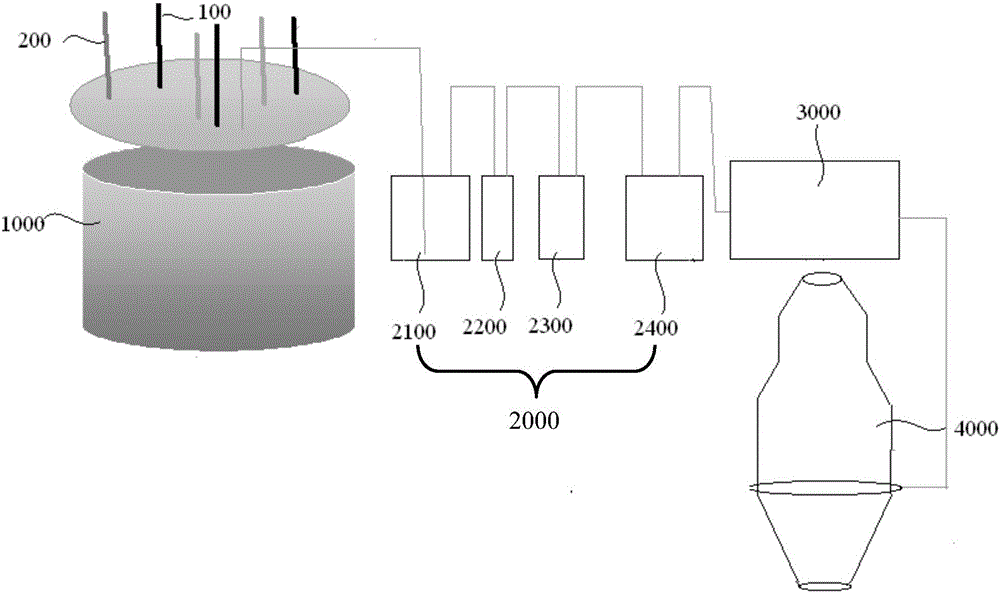

Technology and system for combined use of calcium carbide furnace and vertical furnace

A calcium carbide furnace and calcium carbide technology, applied in the field of metallurgy, can solve the problems of high power consumption, high cost, increased production cost, etc., and achieve the effects of large flue gas production, uniform heat distribution, and saving system investment.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

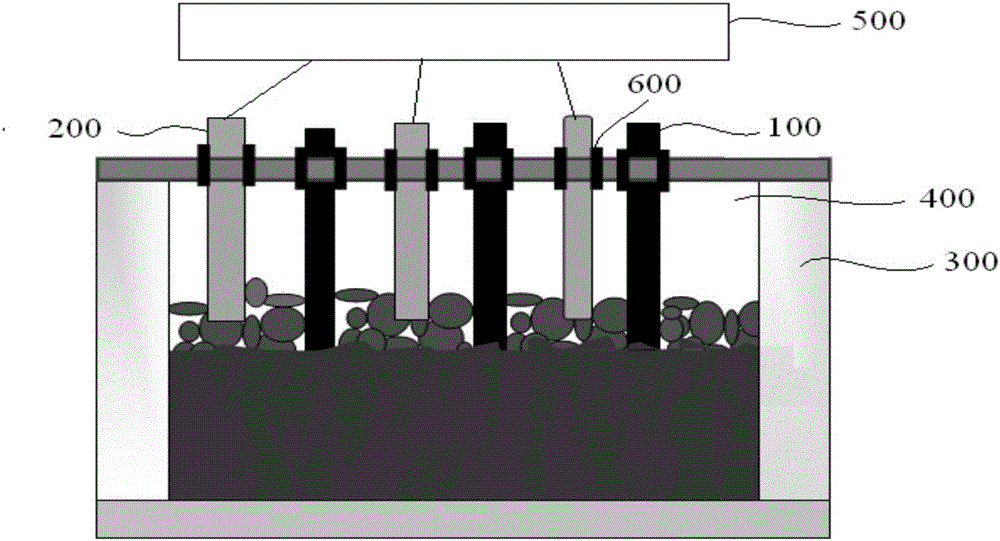

[0055]A calcium carbide furnace with a spray gun includes a furnace cover, a spray gun body, a spray gun lifting device, and an insulating sealing sleeve. The calcium carbide furnace is a calcium carbide furnace with a spray gun installed on the furnace cover, and the spray gun is a copper spray gun. In this embodiment, the spray gun structure is as figure 2 As shown, the spray gun is equipped with oxygen injection pipe, coal powder injection pipe and cooling water pipe. The oxygen injection pipe / coal powder injection pipe is connected with the external oxygen pipe / high-pressure coal powder delivery pipe. When the furnace is sprayed with oxygen and coal, open the control valve to control the pressure and flow. The cooling water pipe of the spray gun is connected with the high-pressure net ring water pipe, so that the cooling water circulates rapidly in the spray gun to ensure that the inlet water temperature is less than 35°C and the outlet water temperature is less than 50°...

Embodiment 2

[0058] A calcium carbide furnace with a spray gun includes a furnace cover, a spray gun body, a spray gun lifting device, and an insulating sealing sleeve. The calcium carbide furnace is a calcium carbide furnace with a spray gun installed on the furnace cover, and the spray gun is a copper spray gun. In this embodiment, the spray gun structure is as figure 2 As shown, the spray gun is equipped with oxygen injection pipe, coal powder injection pipe and cooling water pipe. The oxygen injection pipe / coal powder injection pipe is connected with the external oxygen pipe / high-pressure coal powder delivery pipe. When the furnace is sprayed with oxygen and coal, open the control valve to control the pressure and flow. The cooling water pipe of the spray gun is connected with the high-pressure net ring water pipe, so that the cooling water circulates rapidly in the spray gun to ensure that the inlet water temperature is less than 35°C and the outlet water temperature is less than 50...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com