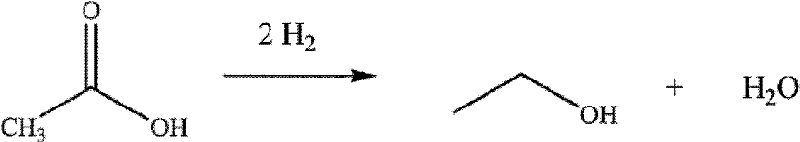

Processes for producing ethanol from acetaldehyde

A technology for acetaldehyde and ethanol, applied in chemical instruments and methods, preparation of organic compounds, catalysts for physical/chemical processes, etc., can solve problems such as limiting ethanol production

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

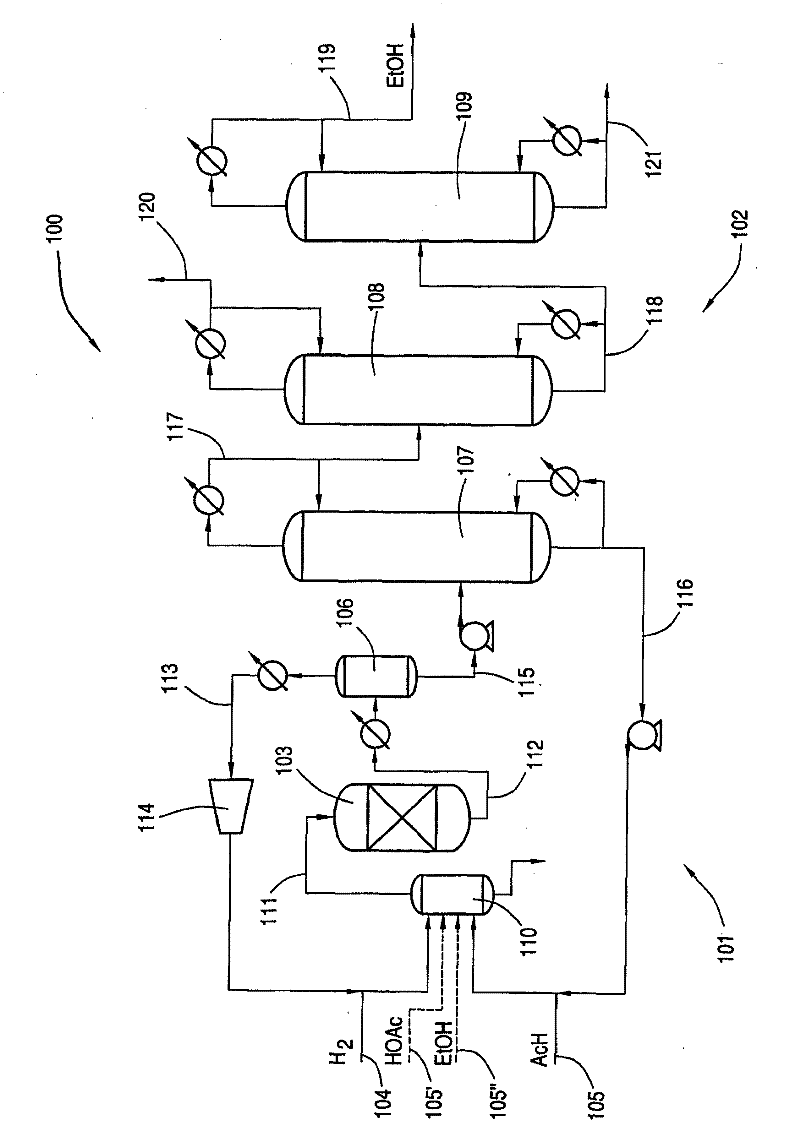

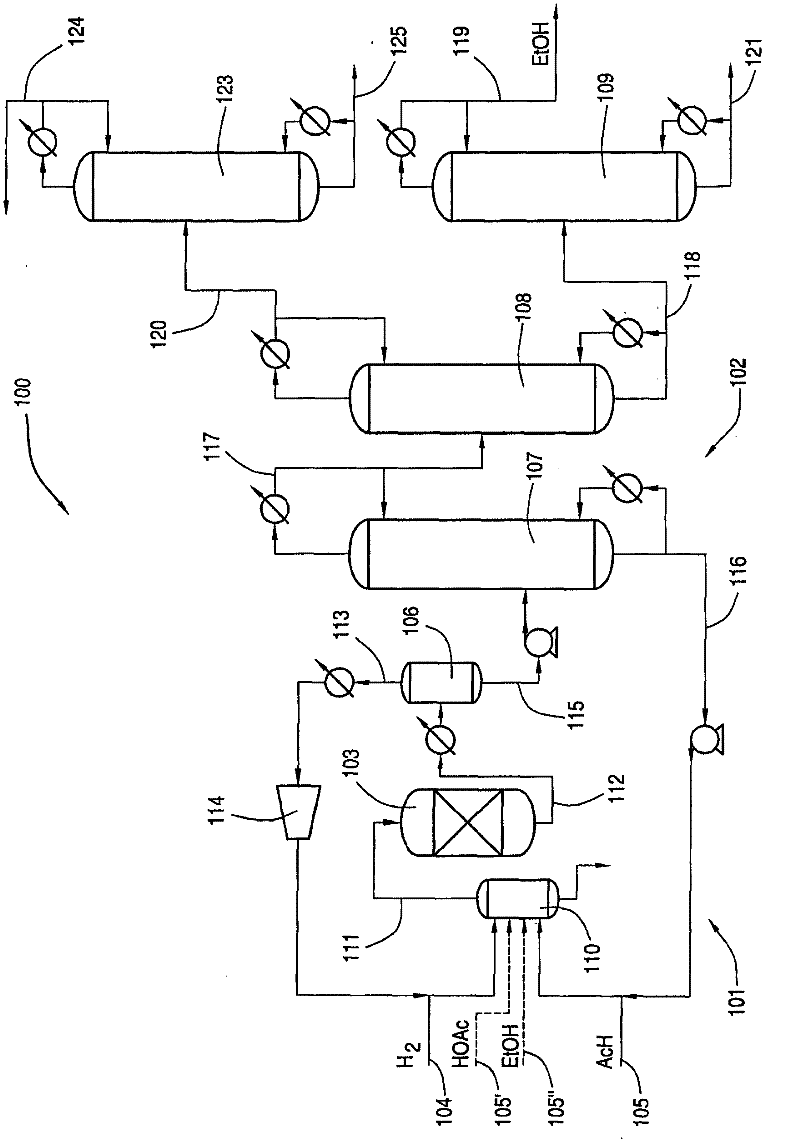

Method used

Image

Examples

Embodiment 1

[0097] An acetaldehyde feed stream comprising 50 wt.% acetaldehyde and 50 wt.% acetic acid was hydrogenated in the presence of a catalyst comprising 1.6 wt.% platinum and 1 wt.% tin. In the gas phase at a temperature of 250°C, a pressure of 250 psig and a rate of 4,500 hr -1 The GHSV undergoes hydrogenation reactions. The composition of the crude ethanol mixture in the reactor effluent is provided in Table 7 below.

Embodiment 2

[0099] The acetaldehyde feed stream was hydrogenated as in Example 1 except at a temperature of 300°C. The composition of the resulting crude ethanol mixture in the reactor effluent is provided in Table 7 below.

Embodiment 3

[0101] An acetaldehyde feed stream having 50 wt.% acetaldehyde and 50 wt.% ethanol was hydrogenated under the conditions described in Example 1. The composition of the resulting crude ethanol mixture in the reactor effluent is provided in Table 7 below.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com