Patents

Literature

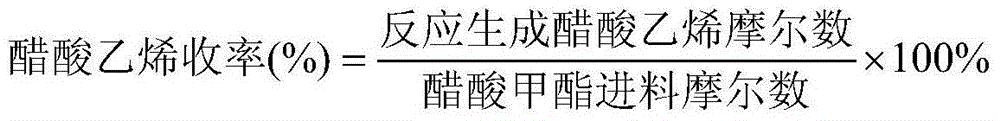

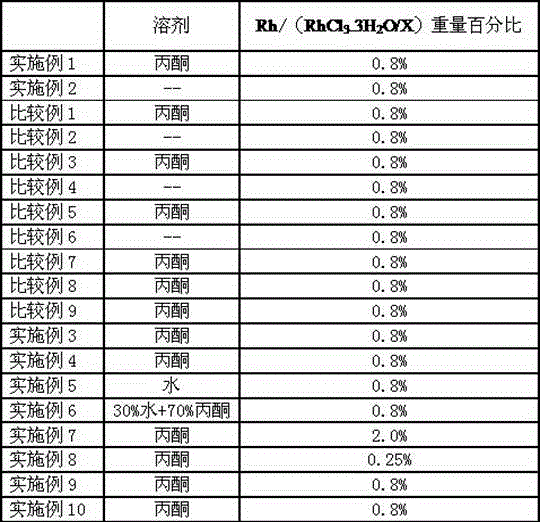

72 results about "Ethylidene diacetate" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

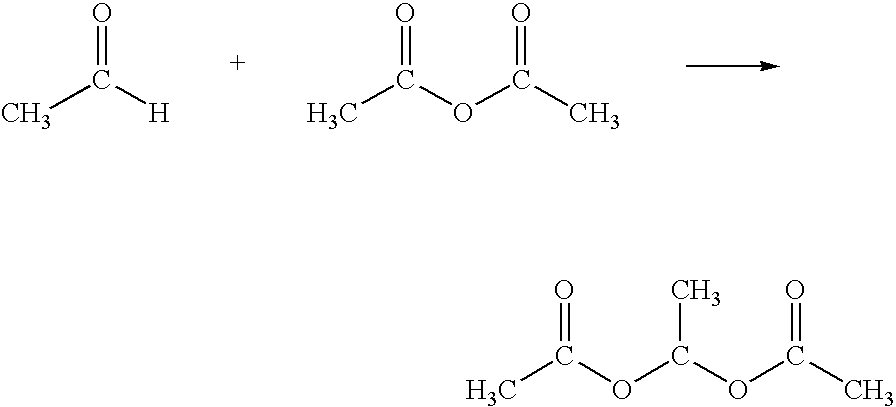

Ethylidene diacetate is an organic compound with the formula (CH₃CO₂)₂CHCH₃. A colorless low-melting solid, it once served as a precursor to vinyl acetate.

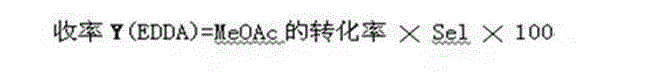

Synthetic method of ethylidene diacetate

ActiveCN103553913AHigh activityImprove stabilityOrganic-compounds/hydrides/coordination-complexes catalystsPreparation by carbon monoxide or formate reactionHydrogenIodide

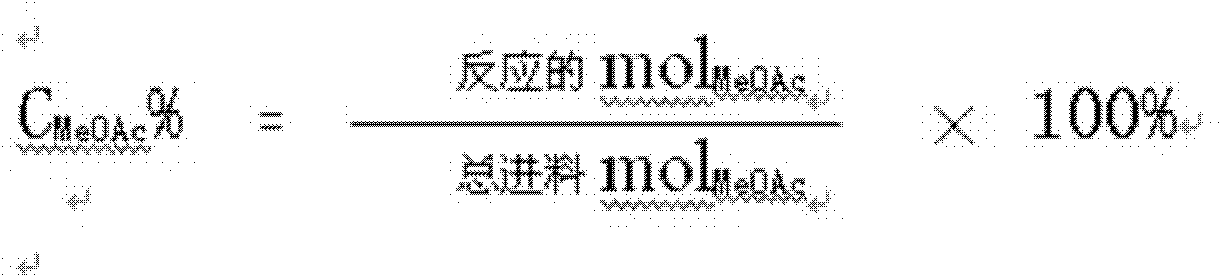

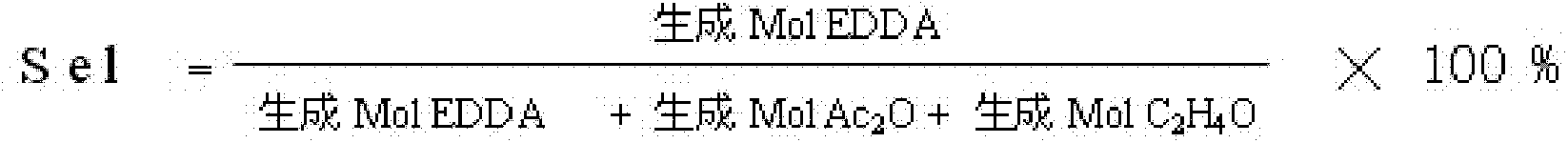

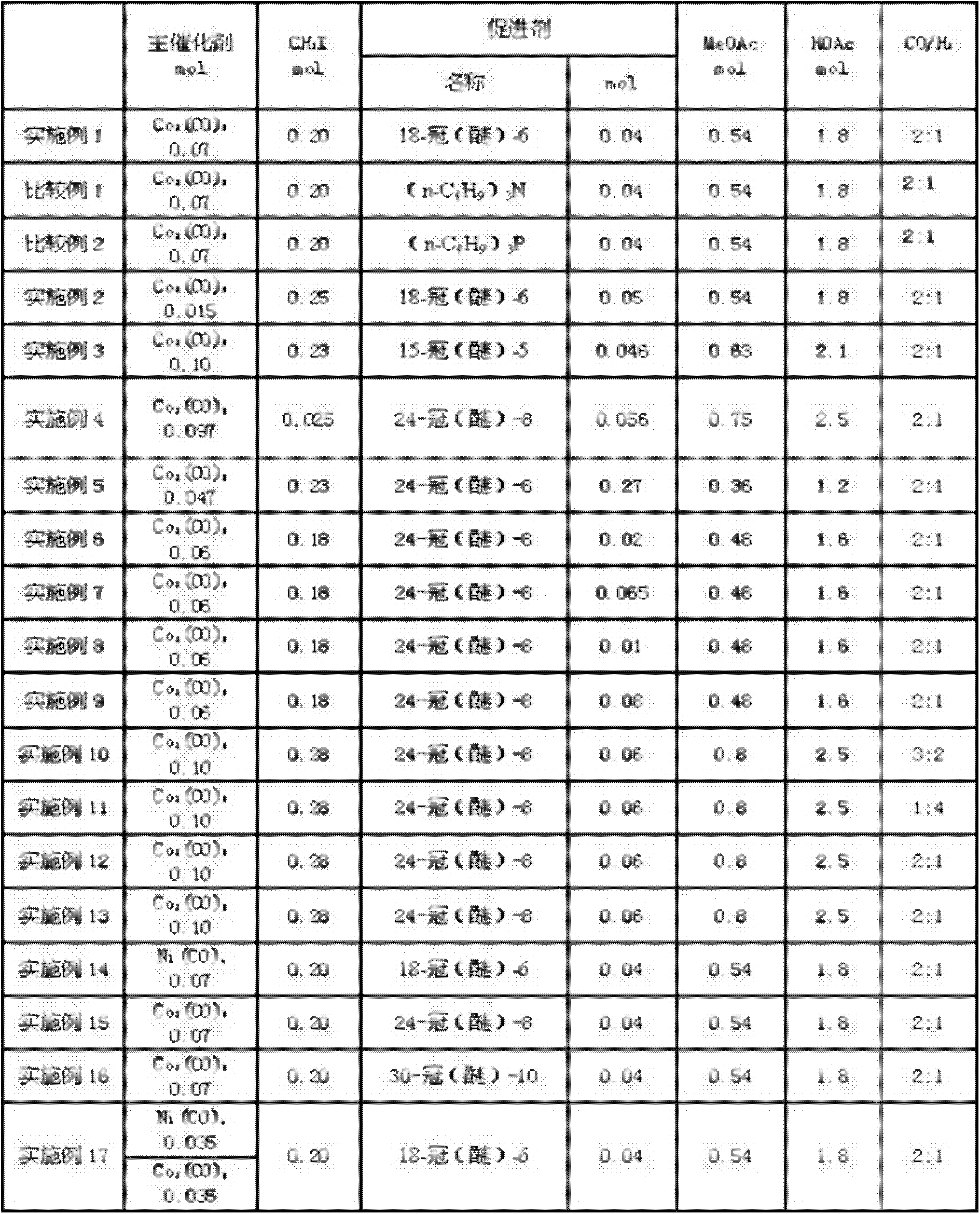

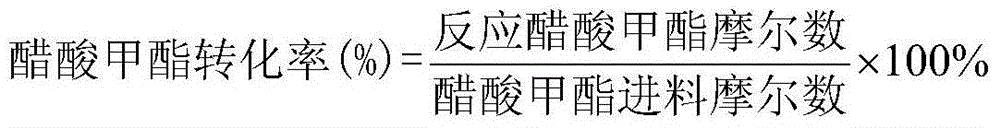

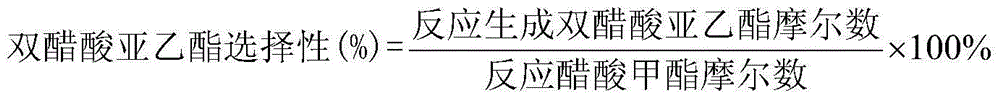

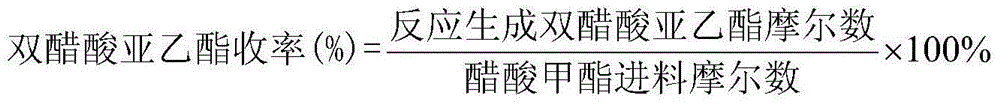

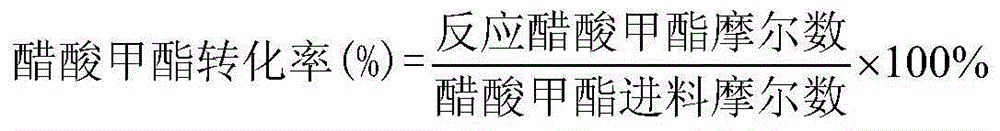

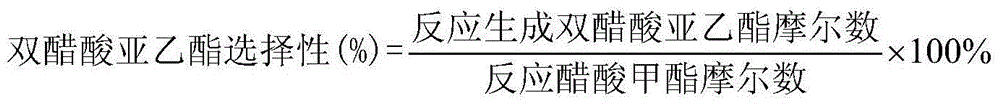

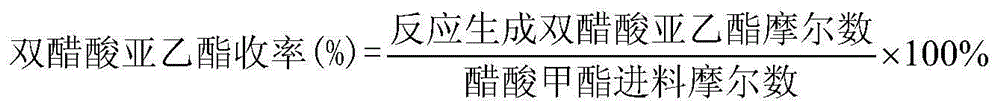

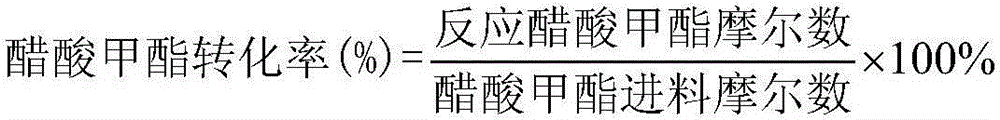

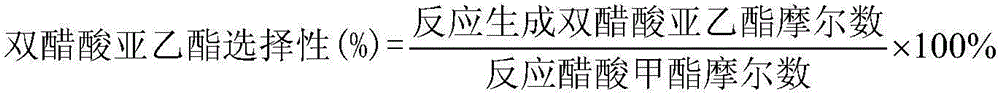

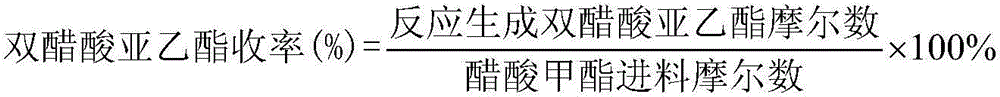

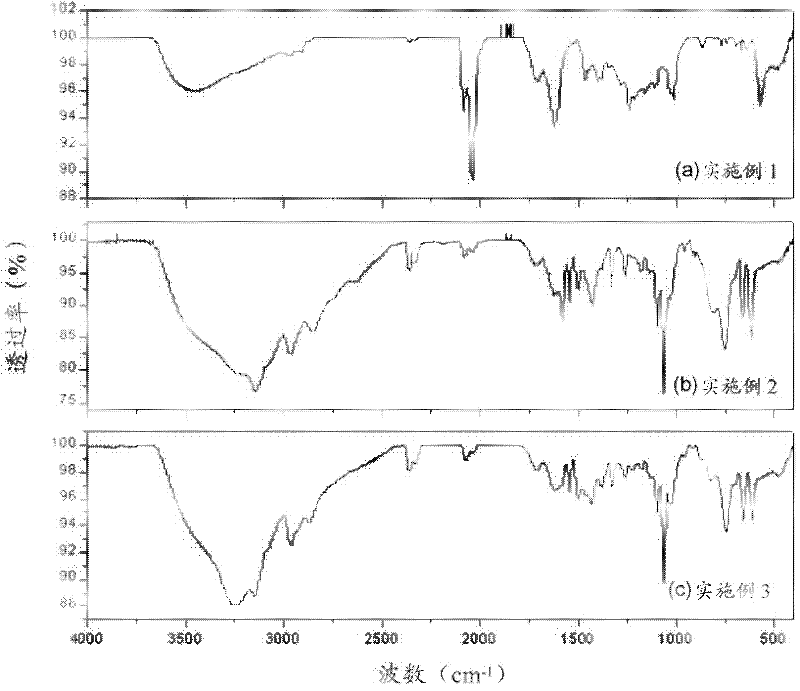

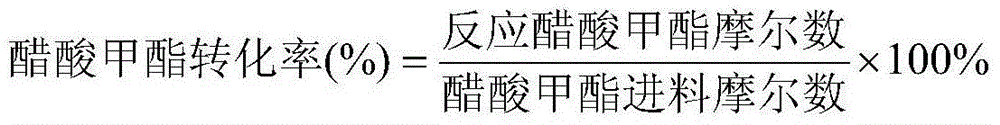

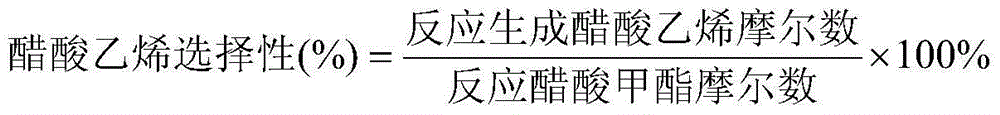

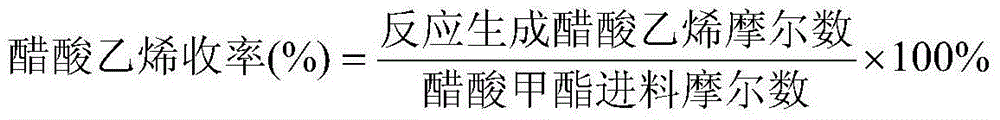

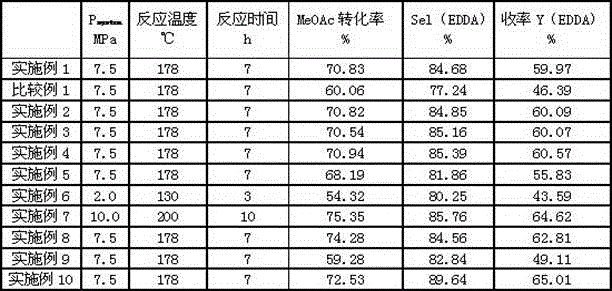

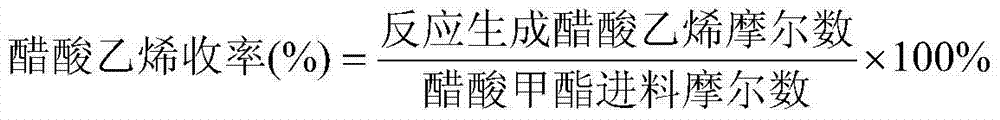

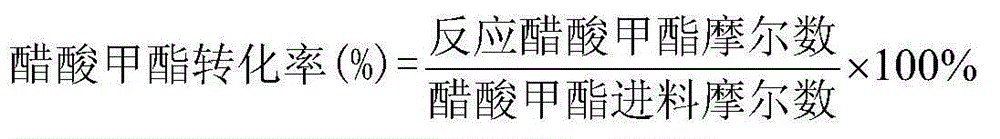

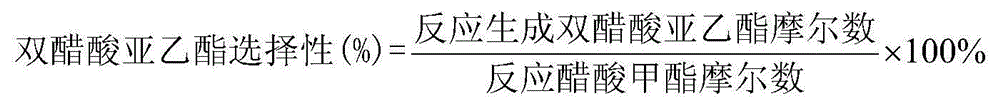

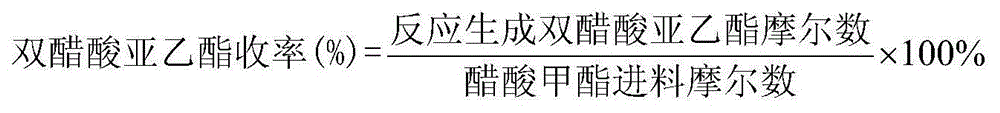

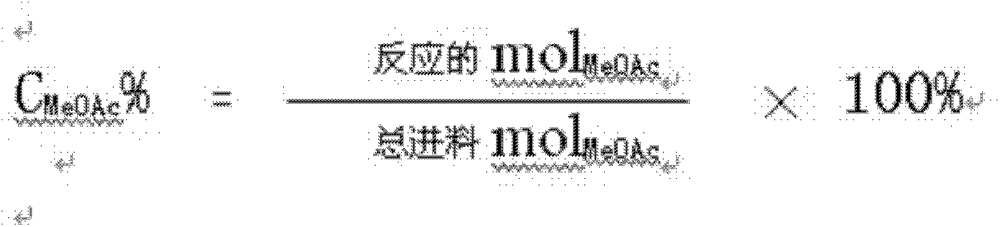

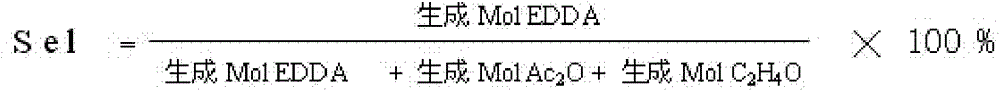

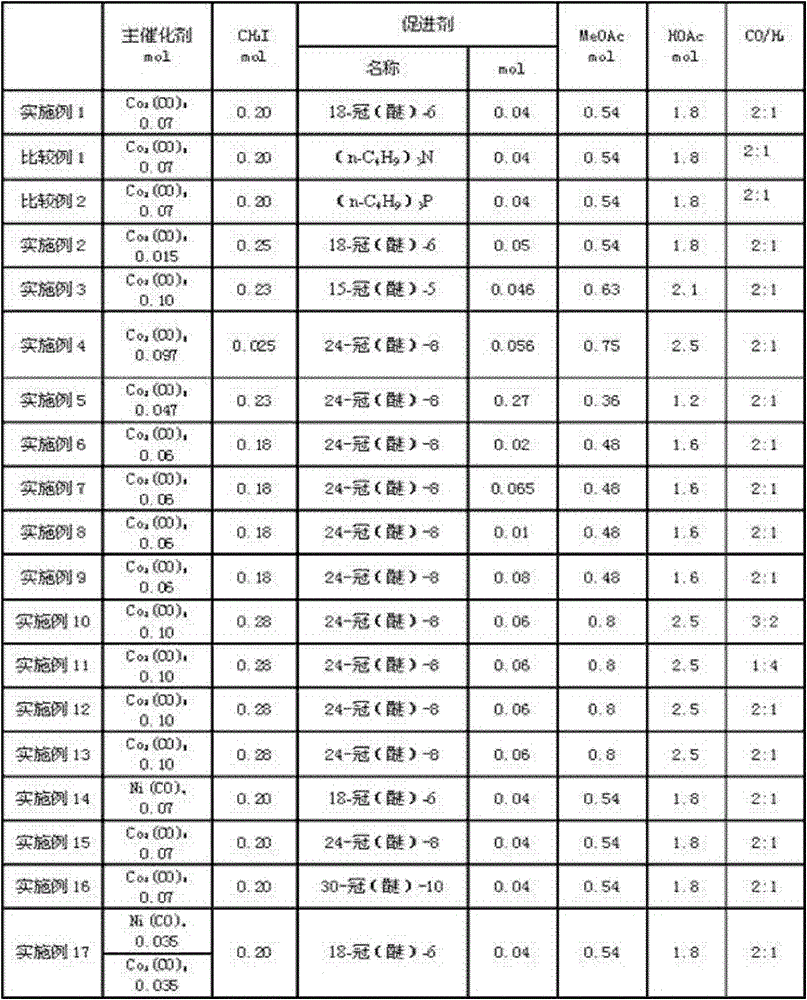

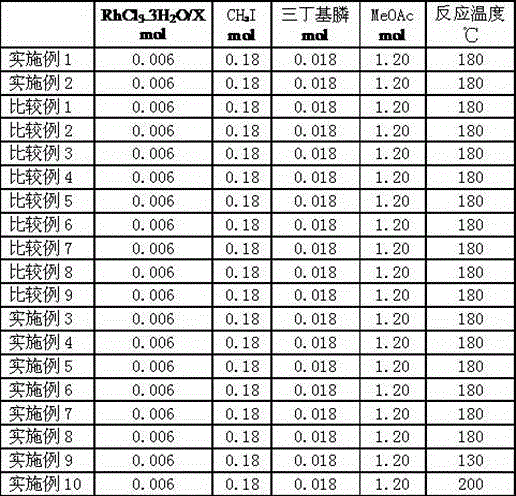

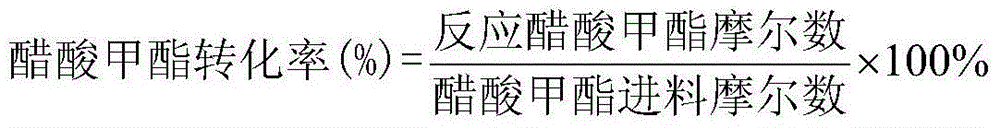

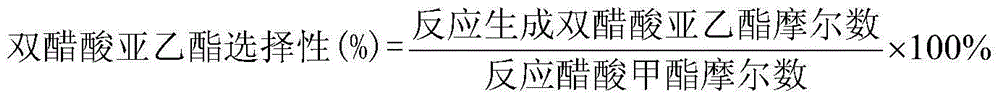

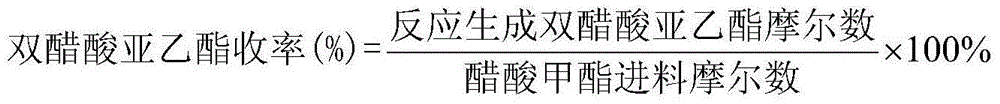

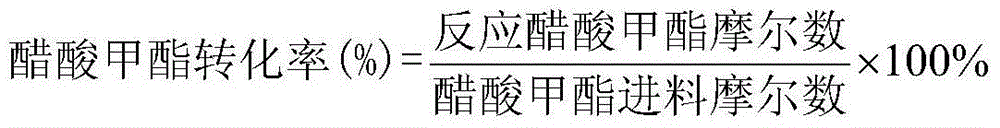

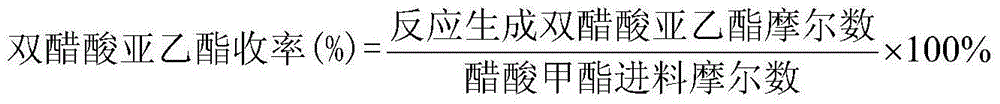

The invention relates to a synthetic method for synthesizing ethylidene diacetate through carbonylation of methyl acetate, mainly solving the problems that the conversion rate of reactant methyl acetate during the synthesis of ethylidene diacetate through carbonylation of methyl acetate is low and the yield and selectivity of ethylidene diacetate are low when organic nitrogen or organic phosphorus is used as an accelerant in the prior art. The technical scheme of the synthetic method is as follows: methyl acetate, carbon monoxide and hydrogen are used as raw materials, acetate acid is used as a solvent, ethylidene diacetate is synthesized under the conditions that the reaction temperature is 130-200 DEG C, the reaction pressure is 2-10MPa and the reaction time is 3-10h, a main catalyst adopts ironic series metals or compounds thereof, a catalyst promoter is iodide and the accelerant is crown ether. By adopting the synthetic method, the problems are well solved, and the synthetic method can be used for production of vinyl acetate.

Owner:CHINA PETROLEUM & CHEM CORP +1

Preparation of acetic acid

ActiveUS20110251422A1Organic compound preparationCarboxylic acid esters preparationAcetic acidAcetic anhydride

The disclosure relates to a process for the preparation of acetic acid. The process comprises reacting a decanter heavy, organic phase of an acetic acid production process with acetic anhydride to convert acetaldehyde in the decanter heavy, organic phase to ethylidene diacetate and separating it from the decanter heavy, organic phase. Ethylidene diacetate can be hydrolyzed to recover acetic acid.

Owner:LYONDELLBASELL ACETYLS

Integrated process for the production of vinyl acetate from acetic acid via acetaldehyde

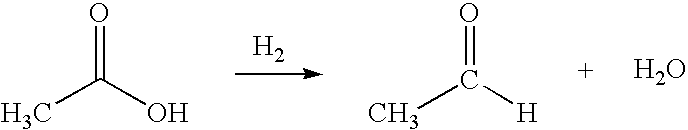

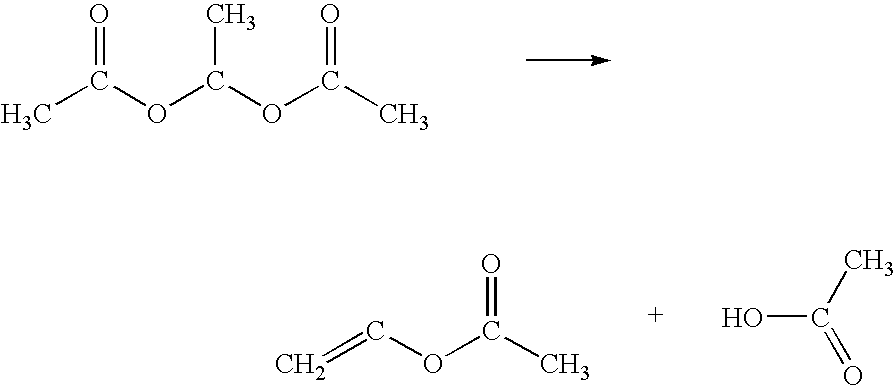

This invention provides an integrated multistep economical process for the production of vinyl acetate monomer (VAM) from acetic acid in the vapor phase. First, acetic acid is selectively hydrogenated over a hydrogenating catalyst composition to form acetaldehyde. Acetaldehyde so formed can be converted to ethylidene diacetate via reaction with acetic anhydride. In a subsequent step so formed ethylidene diacetate is thermally decomposed to form VAM and acetic acid. Alternatively, acetaldehyde formed in the first step can selectively be reacted with ketene to form VAM. In an embodiment of this invention reaction of acetic acid and hydrogen over platinum and iron supported on silica selectively produces acetaldehyde in a vapor phase at a temperature of about 300° C., which is selectively hydrogenated over platinum supported catalyst to form ethanol and dehydrated over NAFION catalyst to form ethylene at a temperature of about 185° C., which is mixed with molecular oxygen, acetic acid and reacted over a palladium / gold / potassium catalyst supported on titania to form VAM at a temperature of about 150° C. to 170° C.

Owner:CELANESE INT CORP

Catalyst used in ethylidene diacetate preparation

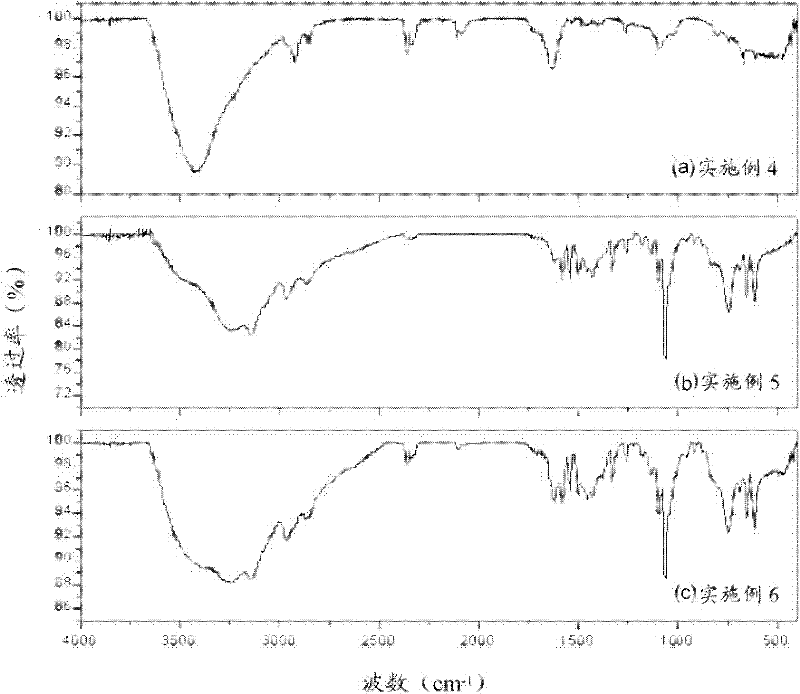

ActiveCN105478127AHigh activityImprove stabilityPreparation by carbon monoxide or formate reactionMetal/metal-oxides/metal-hydroxide catalystsState of artLow activity

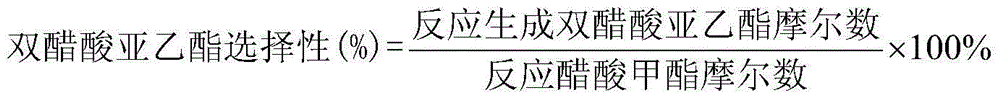

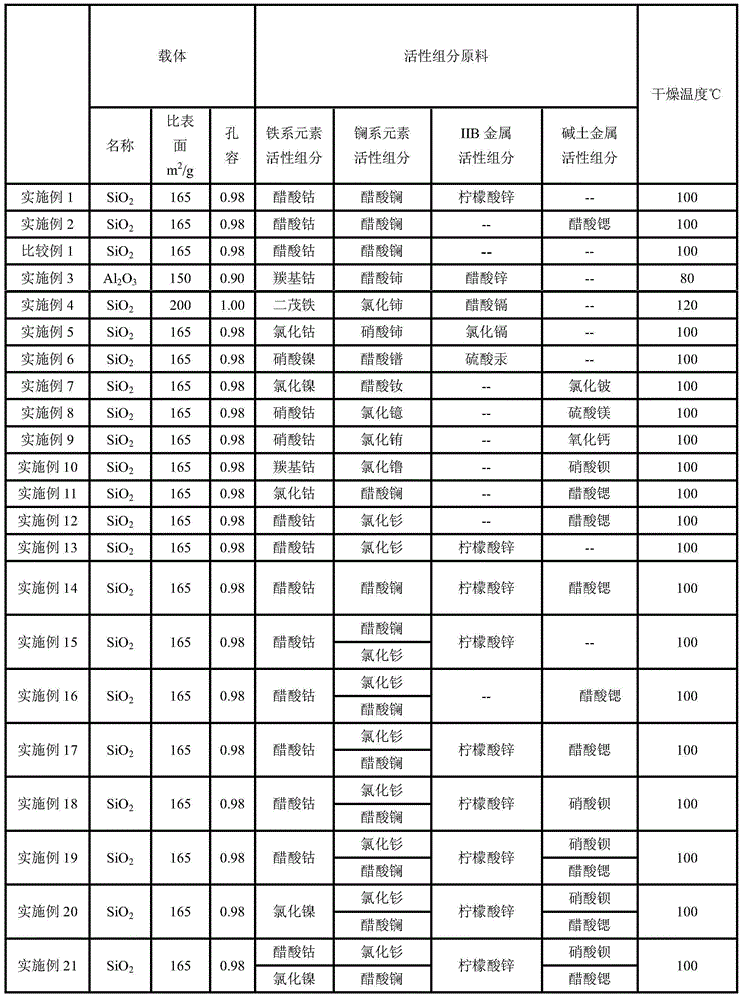

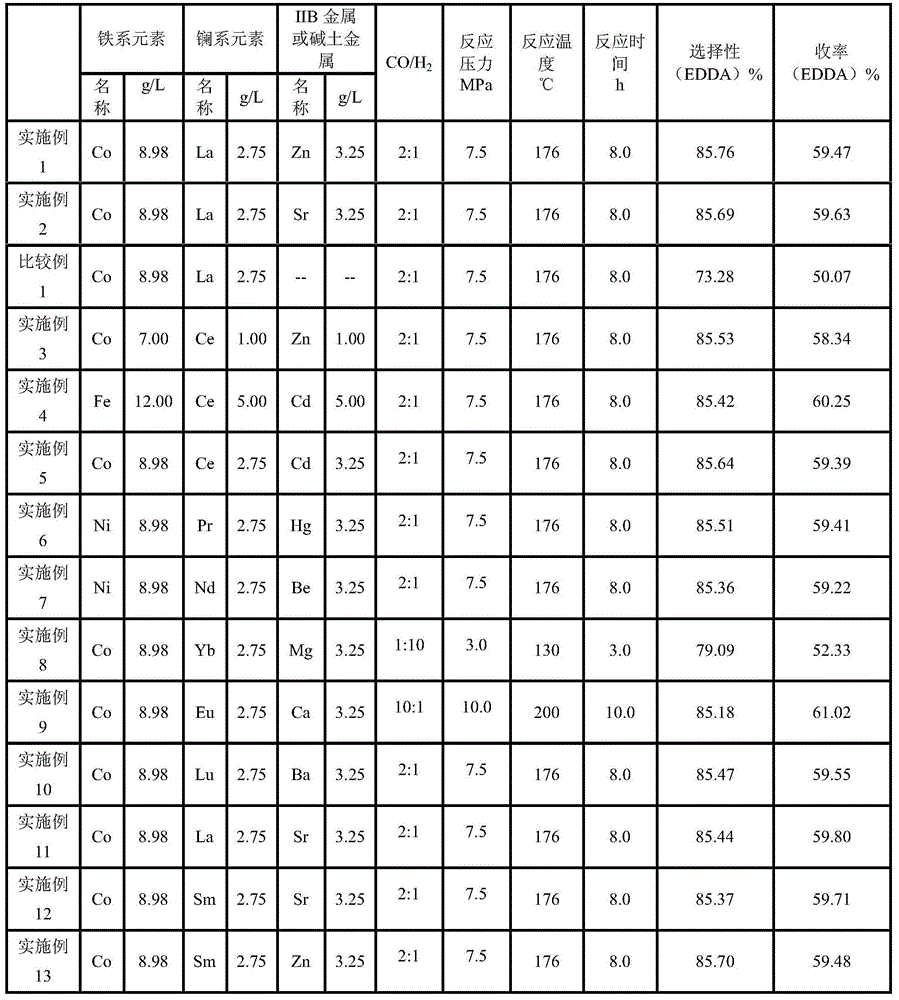

The invention relates to a catalyst used in ethylidene diacetate preparation. The invention mainly aims at solving the problems of relatively low activity and selectivity of the ethylidene diacetate catalysts in prior arts. According to the adopted ethylidene diacetate catalyst, the catalyst adopts a carrier of SiO2 or Al2O3 or a mixture of the two; and active components comprise at least one selected from iron-series elements, at least one selected from IIIB elements, and at least one metal element selected from VA and alkaline earth metals. With the above technical scheme, the technical problem is well solved. The catalyst can be used in vinyl acetate industrial productions.

Owner:CHINA PETROLEUM & CHEM CORP +1

Supported ethylidene diacetate catalyst

ActiveCN105268454AHigh activityImprove stabilityPreparation by carbon monoxide or formate reactionMetal/metal-oxides/metal-hydroxide catalystsLithiumLow activity

The invention relates to a supported ethylidene diacetate catalyst. The catalyst mainly overcomes the problems of low activity and selectivity of ethylidene diacetate catalysts in the prior art. The supported ethylidene diacetate catalyst provided by the invention comprises a supporter and rhodium, copper, lanthanum and lithium which are loaded on the supporter, wherein the supporter is at least one selected from the group consisting of silicon oxide and aluminum oxide; and the supported ethylidene diacetate catalyst perfectly overcomes the above-mentioned technical problems and can be used in industrial production of vinyl acetate.

Owner:CHINA PETROLEUM & CHEM CORP +1

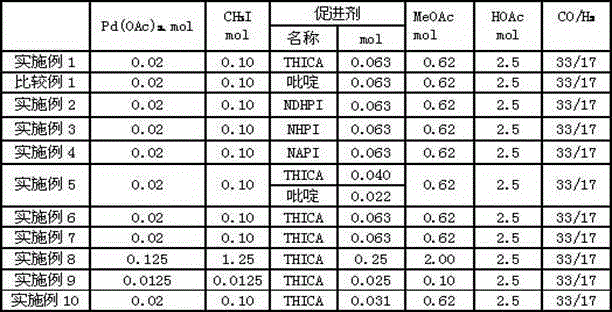

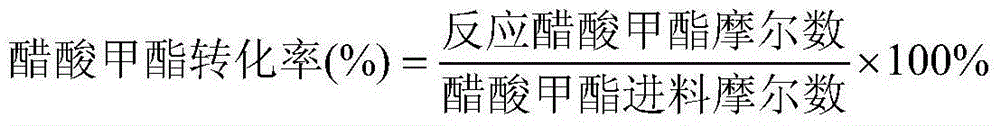

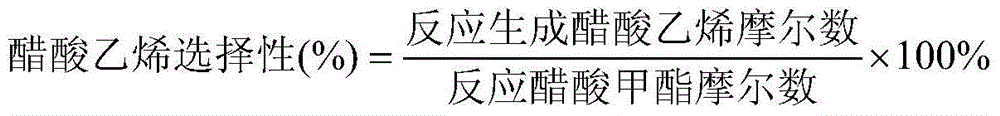

Preparation method of ethylidene diacetate

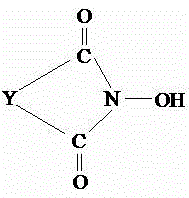

ActiveCN104447318ASolve the problem of selectivityPreparation by carbon monoxide or formate reactionPtru catalystIodide

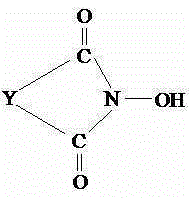

The invention relates to a preparation method of ethylidene diacetate, which is mainly used for solving the problems that in the prior art, conversion rate of methyl acetate using pyridine as a promoter is low, yield of ethylidene diacetate is low and selectivity is low. The method is used for synthesizing the ethylidene diacetate with methyl acetate, carbon monoxide and hydrogen as raw materials and acetic acid as a solvent at a reaction temperature of 130-200 DEG C, a reaction pressure of 2-10 MPa and a reaction time of 3-10 hours, the main catalyst is selected from platinum group metals or compounds thereof, the auxiliary catalyst is an iodide, an oxynitride selected from the general formula (I) is used as the promoter, the technical scheme is used for well solving the problem, and the preparation method can be used in the production of vinyl acetate. The formula is described in the specification.

Owner:CHINA PETROLEUM & CHEM CORP +1

Catalyst used in synthesis of ethylidene diacetate

ActiveCN104549523AHigh activityImprove stabilityOrganic-compounds/hydrides/coordination-complexes catalystsPreparation by carbon monoxide or formate reactionPtru catalystIodide

The invention relates to a catalyst used in the synthesis of ethylidene diacetate and a synthesis method of the ethylidene diacetate, and mainly aims at solving the problems that the yield of the ethylidene diacetate is low and the selectivity is low in the prior art. The catalyst used in the synthesis of the ethylidene diacetate comprises a main catalyst, a catalyst promoter and an accelerator, wherein the main catalyst is Rh metal or a compound of the Rh metal; the catalyst promoter is an iodine compound; and the accelerator is N-heterocyclic carbine and derivatives of the N-heterocyclic carbine. By adopting the technical scheme, the problems are relatively well solved, and the catalyst used in the synthesis of the ethylidene diacetate can be applied to the production of the ethylidene diacetate.

Owner:CHINA PETROLEUM & CHEM CORP +1

Method for synthesis of vinyl acetate through hydroformylation of methyl acetate

ActiveCN105523929AHigh activityImprove stabilityOrganic compound preparationOrganic-compounds/hydrides/coordination-complexes catalystsIron groupMethyl acetate

The invention relates to a method for synthesis of vinyl acetate through hydroformylation of methyl acetate. The method mainly solves the problem that the existing vinyl acetate preparation method utilizing methyl acetate carbonylation and carboxide cracking has a low yield and low selectivity. The method provided through the invention comprises methyl acetate carbonylation for ethylidene diacetate preparation and ethylidene diacetate cracking for vinyl acetate preparation. A carbonylation catalyst utilizes SiO2, Al2O3 or their mixture as a carrier and active ingredients comprise at least one of iron group metal elements, at least one of IIIB elements and at least one of IVA and alkali metals. The method well solves the technical problem and can be used for vinyl acetate industrial production.

Owner:CHINA PETROLEUM & CHEM CORP +1

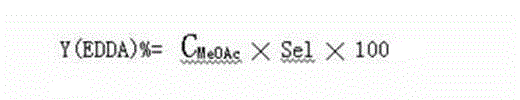

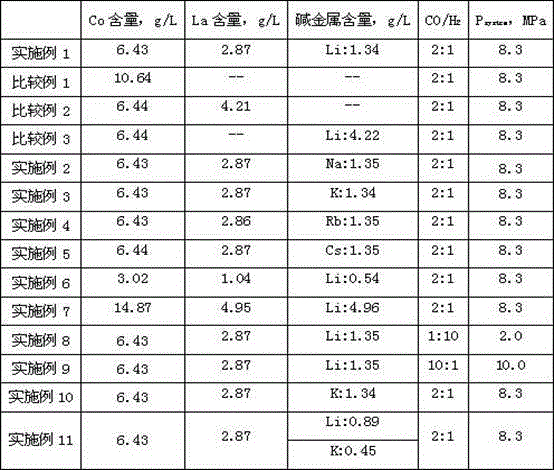

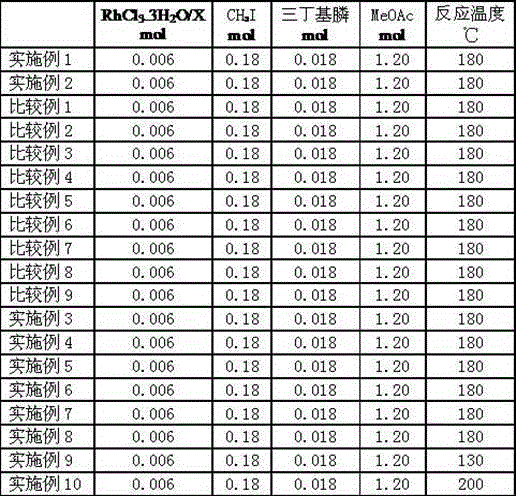

Supported ethylidene diacetate catalyst

ActiveCN104549309AHigh activityImprove stabilityPreparation by carbon monoxide or formate reactionMetal/metal-oxides/metal-hydroxide catalystsPtru catalystEthylic acid

The invention relates to a supported ethylidene diacetate catalyst and a preparation method thereof, and mainly aims to solve the problem of relatively low activity and selectivity of an ethylidene diacetate catalyst in the prior art. The problem can be well solved by adopting a technical scheme that the catalyst comprises a carrier and cobalt, lanthanum and alkali metal which are supported on the carrier, wherein the content of cobalt is 3.0-15.0g / L, the content of lanthanum is 1.0-5.0g / L, and the content of alkali metal is 0.5-5.0g / L; and the carrier is at least one of silicon oxide and aluminum oxide. The catalyst can be used in industrial production of vinyl acetate.

Owner:CHINA PETROLEUM & CHEM CORP +1

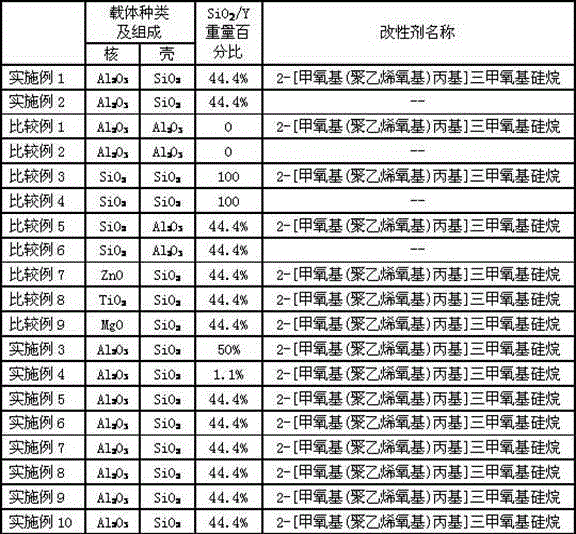

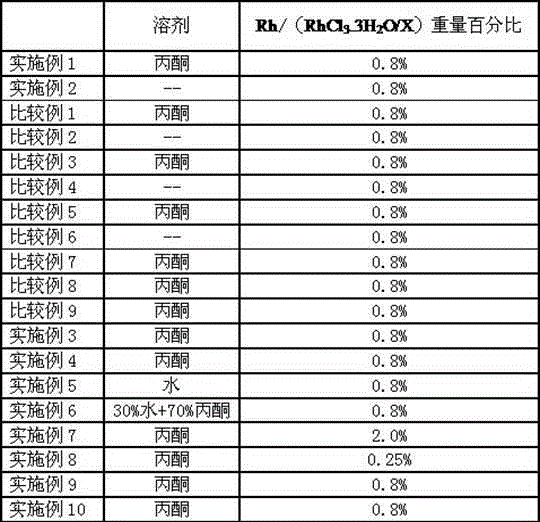

Preparation method for preparing ethylidene diacetate from methyl acetate

ActiveCN104447316AImprove conversion rateHigh selectivityOrganic-compounds/hydrides/coordination-complexes catalystsPreparation by carbon monoxide or formate reactionPtru catalystEthylic acid

The invention relates to a preparation method for preparing ethylidene diacetate from methyl acetate, which mainly solves the problems that the methyl acetate conversion rate is low and the ethylidene diacetate selectivity is low in the prior art. The invention adopts the following technical scheme: the preparation method for preparing ethylidene diacetate from methyl acetate comprises the following step: reacting MeOAc, CO and H2 used as raw materials in the presence of a supported catalyst, a cocatalyst and a promoter, thus generating the ethylidene diacetate, wherein the supported catalyst comprises a core-shell type support and a VIII metal or VIII metal compound supported on the support; the cocatalyst is an iodine-containing compound; the promoter is a nitrogen-oxygen organic substance or phosphorus-containing compound; and the core-shell type support has an amorphous aluminum oxide core and an amorphous silicon oxide shell. Thus, the technical scheme well solves the problems. The invention can be used for production of vinyl acetate.

Owner:CHINA PETROLEUM & CHEM CORP +1

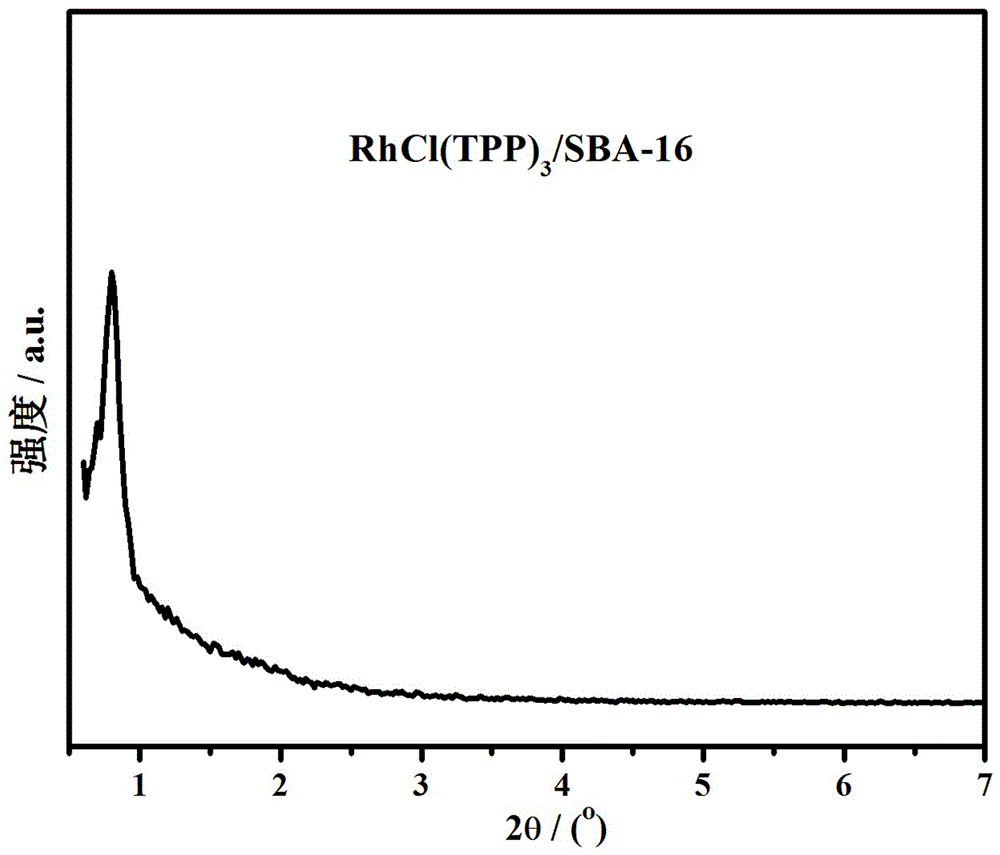

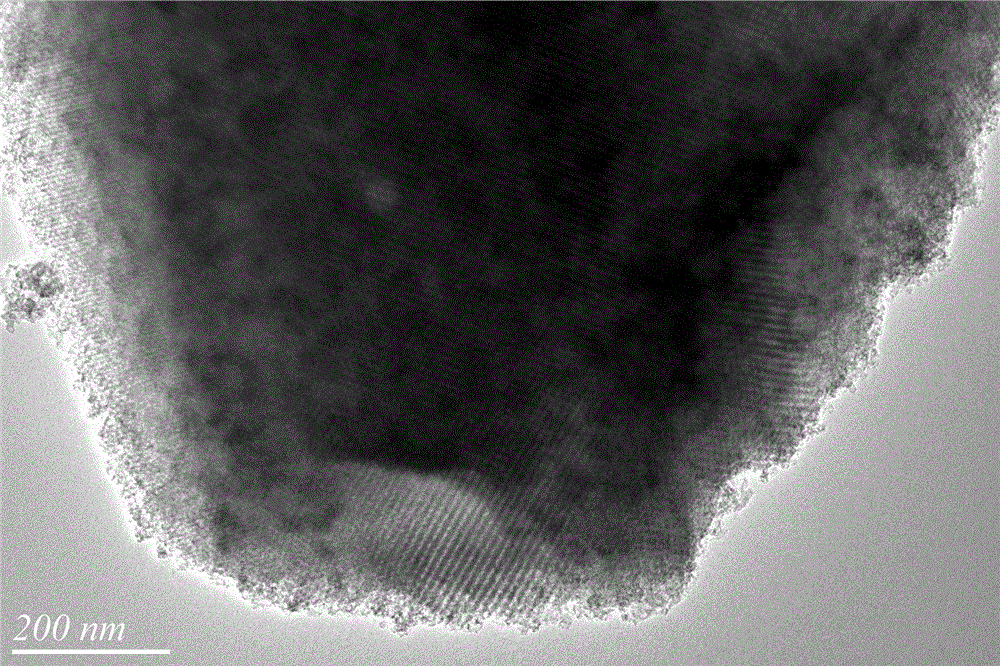

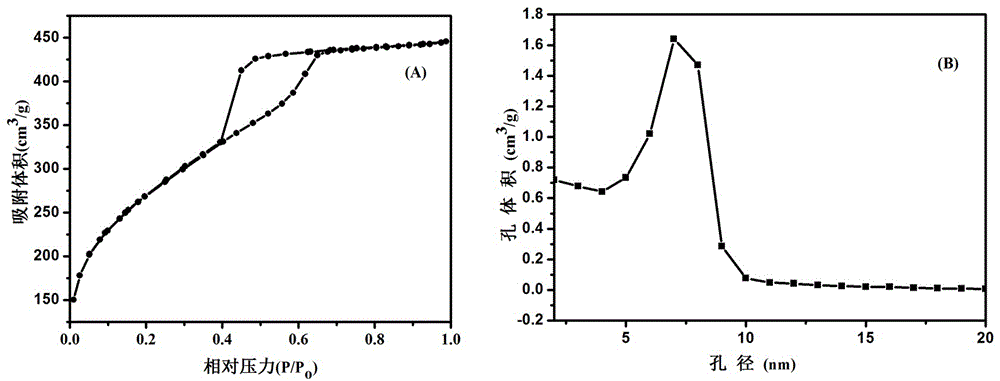

Rhodium metal complex-based mesoporous catalyst, as well as preparation method and application thereof

InactiveCN105772095AHighly ordered three-dimensional cubic mesoporous structureOrdered three-dimensional cubic mesoporous structureOrganic-compounds/hydrides/coordination-complexes catalystsPreparation by carbon monoxide or formate reactionEthyl esterMethyl acetate

The invention discloses a rhodium metal complex-containing mesoporous catalyst for synthesizing ethylidene diacetate by methyl acetate carbonylation reaction. The problems of difficulty in separation, low methyl acetate conversion rate, low ethylidene diacetate yield and low selectivity of an existing homogeneous catalyst are mainly solved. The catalyst consists of an inorganic mesoporous carrier material SBA-16 and a rhodium metal complex dispersed in pore walls of mesopores of the carrier material. The rhodium metal complex is highly uniformly dispersed, higher reactivity and target product selectivity are achieved, and the selectivity of the ethylidene diacetate reaches 70 percent or above.

Owner:TAIYUAN UNIV OF TECH

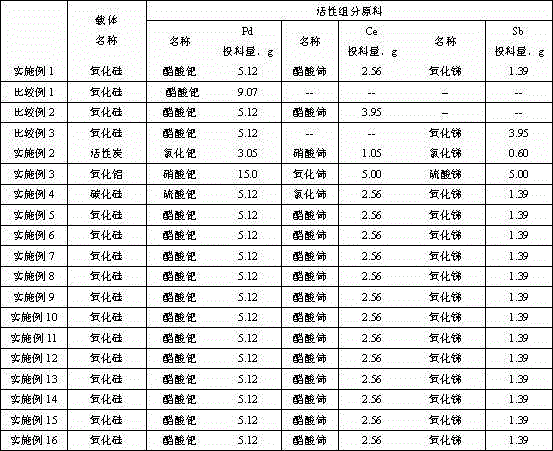

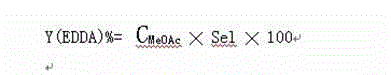

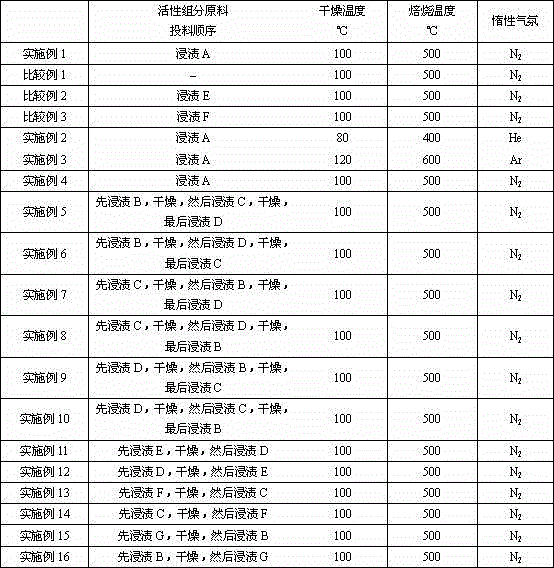

Ethylidene diacetate catalyst and preparation method thereof

ActiveCN104549258AHigh activityImprove stabilityPreparation by carbon monoxide or formate reactionMetal/metal-oxides/metal-hydroxide catalystsActivated carbonCarbide silicon

The invention relates to a catalyst for synthesizing ethylidene diacetate with methyl acetate and a preparation method of the catalyst, which are mainly used for solving the problems of low activity and poor selectivity of an ethylidene diacetate catalyst in the prior part. The technical problems are well solved through the adoption of the technical scheme that the ethylidene diacetate catalyst comprises a carrier, 3.0-15.0 g / L of palladium, 1.0-5.0 g / L of cerium and 0.5-5.0 g / L of stibium, wherein palladium, cerium and stibium are loaded on the carrier, and the carrier is at least one of activated carbon, silicon oxide, aluminum oxide and silicon carbide. The catalyst can be used in industrial production of vinyl acetate.

Owner:CHINA PETROLEUM & CHEM CORP +1

Ethylidene diacetate catalyst and production method thereof

ActiveCN105413684AHigh activityImprove stabilityPreparation by carbon monoxide or formate reactionMetal/metal-oxides/metal-hydroxide catalystsActive ingredientAlkali metal

The invention relates to an ethylidene diacetate catalyst and a production method thereof and mainly solves the problem that in the prior art, the ethylidene diacetate catalyst is relatively low in activity and selectivity. By adopting a technical scheme that the ethylidene diacetate catalyst uses SiO2, Al2O3 or a mixture thereof as a carrier and an active ingredient comprises rhodium, alkali metals and at least one metal element selected from IVA and VA, the technical problem is better solved, and the catalyst can be used for industrial production of vinyl acetate.

Owner:CHINA PETROLEUM & CHEM CORP +1

Catalyst used in ethylidene diacetate preparation

ActiveCN105478115AHigh activityImprove stabilityPreparation by carbon monoxide or formate reactionMetal/metal-oxides/metal-hydroxide catalystsAlkaline earth metalLanthanide

The invention relates to a catalyst used in ethylidene diacetate preparation. The invention mainly aims at solving the problems of relatively low activity and selectivity of the ethylidene diacetate catalysts in prior arts. According to the adopted ethylidene diacetate catalyst, the catalyst adopts a carrier of SiO2 or Al2O3 or a mixture of the two; and active components comprise at least one selected from platinum-family metals, at least one selected from alkaline earth metals and at least on metal element selected from IVA and lanthanide-series metal elements. With the above technical scheme, the technical problem is well solved. The catalyst can be used in vinyl acetate industrial productions.

Owner:CHINA PETROLEUM & CHEM CORP +1

High-strength flame-retardant alkali battery PP sealing ring and preparation method therefor

InactiveCN107706324AExcellent low temperature toughening effectImprove low temperature embrittlement performanceFinal product manufactureCell sealing materialsPolypropyleneArc resistance

The invention discloses a high-strength flame-retardant alkali battery PP sealing ring. The sealing ring comprises the following raw materials in parts by weight: 100 parts of polypropylene, 5-15 parts of maleic anhydride grafted ethylene propylene diene monomer, 3-8 parts of ethylene-vinyl acetate copolymer with 5-25% of vinyl acetate, 3-8 parts of SEBS thermoplastic elastomer, 2-6 parts of flameretardant additive, 4-10 parts of irregular glass fibers, and 0.5-2 parts of 1, 1-ethylidene diacetate. The alkali battery sealing ring provided by the invention has excellent electrical insulativityand corrosion resistance, high arc resistance, excellent high-and-low temperature resistance, relatively high mechanical strength, relatively high flame retardancy and water absorption and low gas transmittance, and the electrical performance is less affected by humidity, stable temperature and frequency; and in addition, the raw material combination is high in fluidity in the sealing ring forming and processing, so that generation of unqualified products caused by the phenomena of insufficient injection, insufficient filling and the like in the production process of the sealing ring can beavoided effectively, so that the sealing ring is a polypropylene sealing ring with excellent comprehensive performance and used for the alkali battery.

Owner:无锡九宇宝新能源科技有限公司

Preparation of acetic acid

ActiveUS8519181B2Organic compound preparationCarboxylic acid esters preparationAcetic acidAcetic anhydride

Owner:LYONDELLBASELL ACETYLS

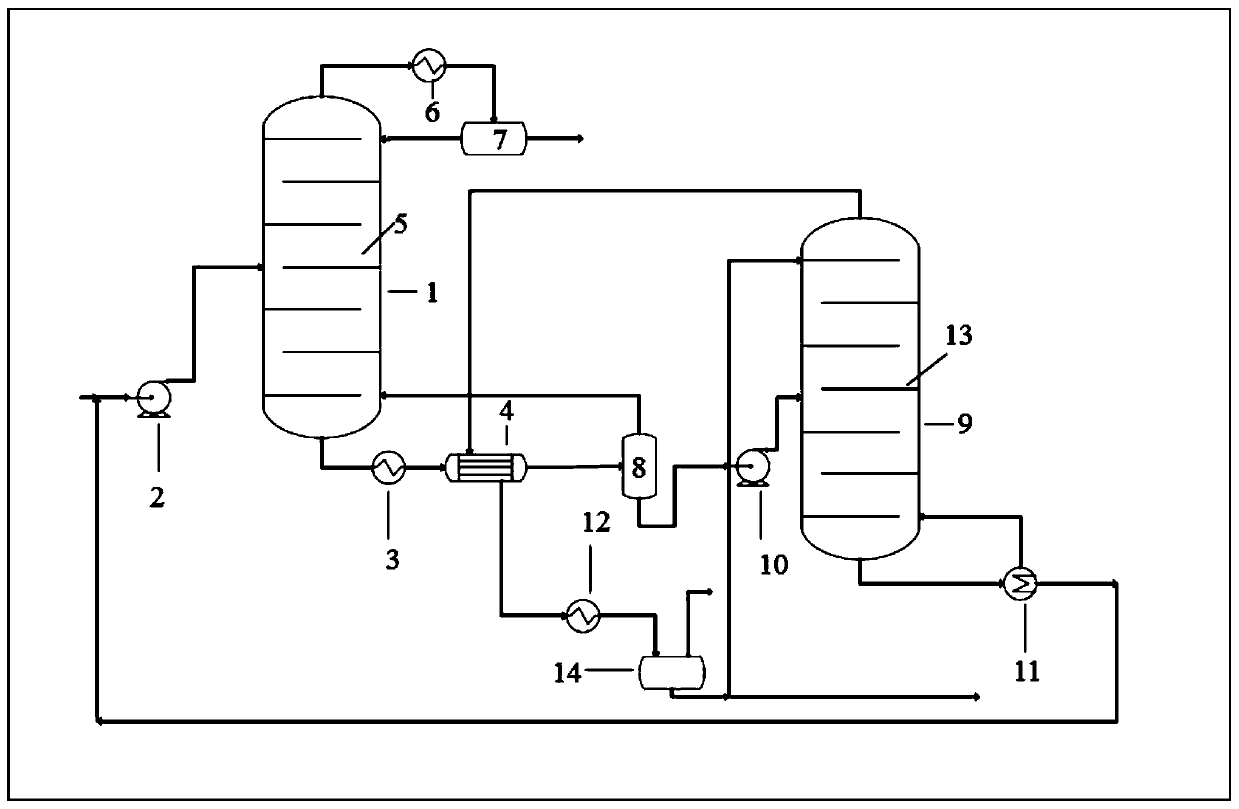

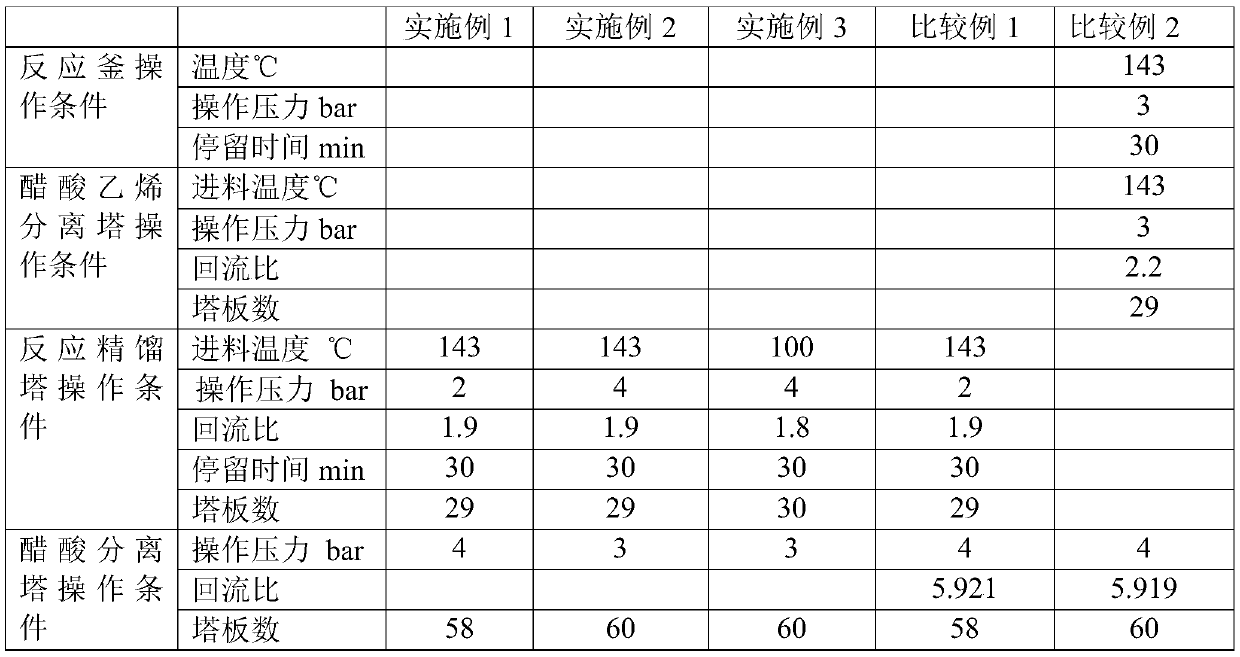

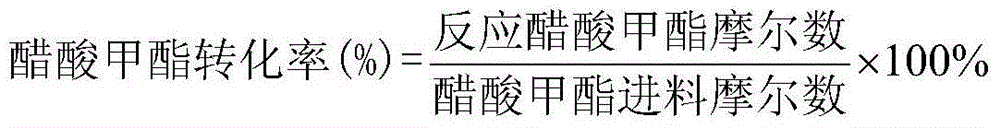

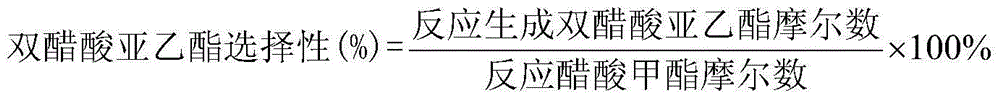

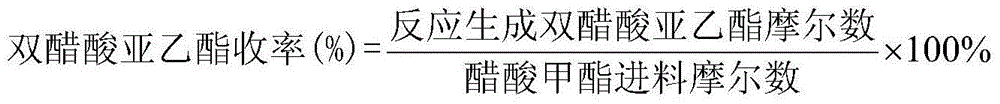

Method and device for preparing vinyl acetate through reactive distillation

ActiveCN110818563AShort reaction residence timeReduce the chance of polymerization side reactionsOrganic compound preparationCarboxylic acid esters preparationAcetic anhydrideEthylic acid

The invention belongs to the field of vinyl acetate production. The invention particularly relates to a method and a device for preparing vinyl acetate through reactive distillation. The method comprises the following steps: introducing ethylidene diacetate, an acidic cracking agent and acetic anhydride into a reactive rectifying tower consisting of a rectifying section and a stripping section toprepare and separate high-purity vinyl acetate, extracting the VAC (vinyl acetate) from the top of the rectifying tower, extracting acetic acid, acid anhydride, the cracking agent, byproducts, EDA andimpurities from the tower bottom, and introducing into an acetic acid separation tower. The acetic acid is extracted from the top of the acetic acid separation tower and sent to an esterification reaction section for producing methyl acetate, the acetic anhydride and the cracking agent are extracted from the tower bottom, and the EDA returns to the rectifying tower. The purity of the obtained VACis 99.9 wt% or above, compared with a traditional reaction kettle-rectifying tower process, back mixing of materials is reduced, the conversion rate of the EDA, the yield of the VAC and the product purity are improved, a reboiler of the reaction rectifying tower is coupled with a tower top condenser of the acetic acid separation tower, and energy consumption is remarkably reduced.

Owner:CHANGZHOU UNIV

Catalyst for synthesizing ethylidene diacetate

ActiveCN105413686AHigh activityImprove stabilityPreparation by carbon monoxide or formate reactionMetal/metal-oxides/metal-hydroxide catalystsLanthanideEthyl ester

The invention relates to a catalyst for synthesizing ethylidene diacetate and mainly solves the problem that in the prior art, the ethylidene diacetate catalyst is relatively low in activity and selectivity. By adopting a technical scheme that the ethylidene diacetate catalyst uses SiO2, Al2O3 or a mixture thereof as a carrier and an active ingredient comprises at least one selected from platinum group metals, at least one selected from VIB, and at least one metal element selected from IB and lanthanide metal elements, the technical problem is better solved, and the catalyst can be used for industrial production of vinyl acetate.

Owner:CHINA PETROLEUM & CHEM CORP +1

Method for preparing carboxyl anhydride

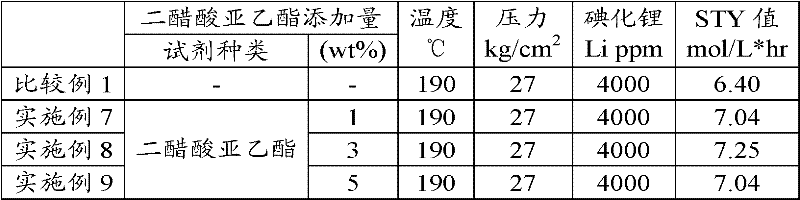

InactiveCN102476988AReduce formationImproved space-time yieldCarboxylic acid anhydrides preparationAlkali metalCarboxylate

The present invention relates to a method for preparing carboxyl anhydride. The method comprises adopting carboxylate derived from alcohol and carboxylic acid and carbon monoxide containing a small amount of hydrogen gas as raw material, and allowing oxonation in a liquid reaction medium in the presence of group VIIIB catalyst to produce carboxyl anhydride. The liquid reaction medium includes the group VIIIB catalyst, organic halide, carboxylate, alkali metal salt, carboxyl anhydride, carboxylic acid, a protectant N-acetylimidazole, and an organic additive ethylidene diacetate (EDA). The method avoids reaction of metal ions and EDA and decreases insoluble tar generated during reaction by using the protectant N-acetylimidazole, and improves whole oxonation rate by maintaining the content of the organic additive EDA at a constant level.

Owner:CHINA PETROCHEM DEVMENT

High-thermal-stability alkaline battery PA sealing ring and preparation method thereof

InactiveCN107501929AImprove insulation performanceImprove corrosion resistanceCell sealing materialsElectrical batteryPolyethylene terephtalate

The invention discloses a high-thermal-stability alkaline battery PA sealing ring and a preparation method thereof. The high-thermal-stability alkaline battery PA sealing ring is prepared from the following raw materials in parts by weight: 100 parts of nylon 66, 8 to 16 parts of poly(trimethylene terephthalate), 5 to 10 parts of polypropylene, 10 to 20 parts of compatilizer, 3 to 8 parts of SEBS thermoplastic elastomer, 2 to 6 parts of flame retardant additive and 0.5 to 2 parts of 1,1-ethylidene diacetate. The alkaline battery sealing ring disclosed by the invention has the advantages of electrical insulating property, corrosion resistance, oil resistance, arc resistance, good mechanical property, good gas barrier property and good fatigue durability. By means of blending modification among raw materials, water absorption, thermal stability and processability of the nylon sealing ring are effectively improved; furthermore, the raw material combination has good fluidity in sealing ring forming processing, so that rejected products caused by the phenomena of insufficient injection, insufficient fill and the like in a sealing ring production process are prevented from being generated; the alkaline battery nylon sealing ring has excellent comprehensive performance.

Owner:无锡九宇宝新能源科技有限公司

Synthetic method for vinyl acetate

ActiveCN105585487AHigh activityImprove stabilityOrganic compound preparationCarboxylic acid esters preparationPlatinumActive component

The invention relates to a synthetic method for vinyl acetate and is mainly to solve the problems of low yield and selectivity of vinyl acetate in preparation for vinyl acetate from methyl acetate successively through carbonylation and cracking routes. According to a technical scheme of the invention, the synthetic method for vinyl acetate comprises the following steps: subjecting methyl acetate to carbonylation so as to obtain ethylidene diacetate, and subjecting ethylidene diacetate to cracking so as to obtain vinyl acetate, wherein a carbonylation catalyst uses SiO2, Al2O3 or a mixture of SiO2 and Al2O3 as a carrier; an active component is at least one selected from the group consisting of platinum-cluster metals, at least one selected from the group consisting of group-VIB metals, and at least one selected from the group consisting of group-IB metals and lanthanide series metals; thus, the above-mentioned technical problems are well solved, and the synthetic method can be applied in industrial production of vinyl acetate.

Owner:CHINA PETROLEUM & CHEM CORP +1

The preparation method of diethylene acetate

ActiveCN104447318BHigh activityImprove stabilityPreparation by carbon monoxide or formate reactionHydrogenIodide

The invention relates to a preparation method of ethylidene diacetate, which is mainly used for solving the problems that in the prior art, conversion rate of methyl acetate using pyridine as a promoter is low, yield of ethylidene diacetate is low and selectivity is low. The method is used for synthesizing the ethylidene diacetate with methyl acetate, carbon monoxide and hydrogen as raw materials and acetic acid as a solvent at a reaction temperature of 130-200 DEG C, a reaction pressure of 2-10 MPa and a reaction time of 3-10 hours, the main catalyst is selected from platinum group metals or compounds thereof, the auxiliary catalyst is an iodide, an oxynitride selected from the general formula (I) is used as the promoter, the technical scheme is used for well solving the problem, and the preparation method can be used in the production of vinyl acetate. The formula is described in the specification.

Owner:CHINA PETROLEUM & CHEM CORP +1

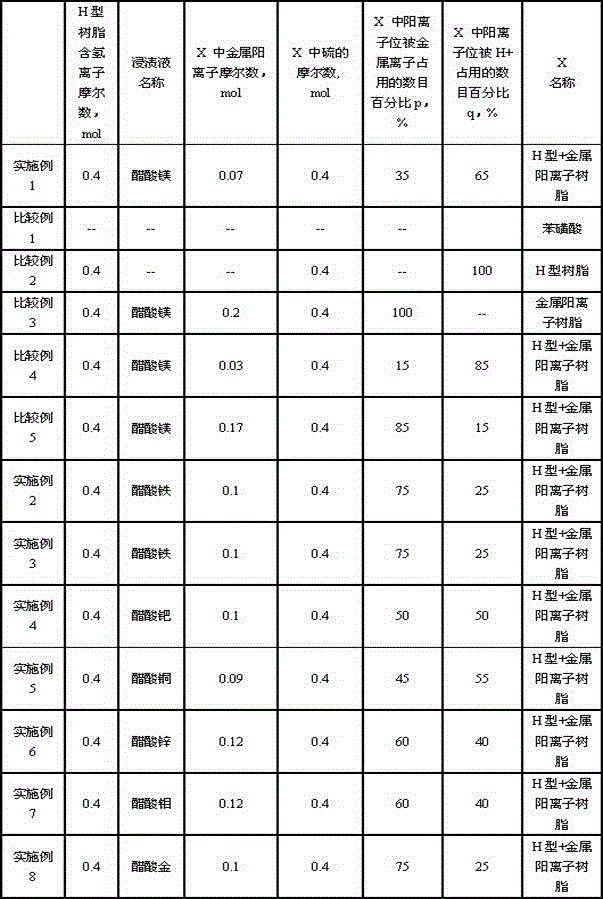

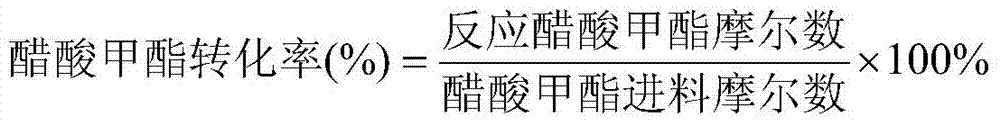

Diethylene acetate method vinyl acetate catalyst and vinyl acetate synthesis method

ActiveCN104549501BOrganic compound preparationOrganic-compounds/hydrides/coordination-complexes catalystsAlkaline earth metalSynthesis methods

The invention relates to an ethylidene diacetate method vinyl acetate catalyst and a vinyl acetate synthesis method, which are mainly used for solving the problems of low ethylidene diacetate conversion rate and poor vinyl acetate selectivity in the prior part. The problems are well solved through the adoption of the technical scheme that the catalyst is cation exchange resin which contains H+ and metal ions, wherein the metal ions are selected from at least one of alkaline-earth metal ions and transition metal ions, the metal ions accounts for a percentage p (20%-80%) of cation sites in the cation exchange resin, and H+ accounts for a percentage q (1 minus p) of the cation sites. The catalyst can be used in production of vinyl acetate.

Owner:CHINA PETROLEUM & CHEM CORP +1

Process for the production of vinyl acetate

The invention relates to a method for production of vinyl acetate, and is mainly to solve the problem of low yield and selectivity of vinyl acetate in preparation for vinyl acetate from methyl acetate successively through carbonylation and cracking routes. According to a technical scheme of the invention, the method for production of vinyl acetate comprises the following steps: subjecting methyl acetate to carbonylation so as to obtain ethylidene diacetate, and subjecting ethylidene diacetate to cracking so as to obtain vinyl acetate, wherein a carbonylation catalyst uses SiO2, Al2O3 or a mixture of SiO2 and Al2O3 as a carrier; an active component comprises at least one selected from the group consisting of iron series elements, lanthanum series elements, and at least one metal element selected from the group consisting of group-IB and alkali metals; thus, the above-mentioned technical problem is well solved, and the method can be applied in industrial production of vinyl acetate.

Owner:CHINA PETROLEUM & CHEM CORP +1

Catalyst for producing ethylidene diacetate

ActiveCN105413701APreparation by carbon monoxide or formate reactionMetal/metal-oxides/metal-hydroxide catalystsState of artActive component

The invention relates to a catalyst for producing ethylidene diacetate, and mainly solves the problem that a catalyst for ethylidene diacetate in the prior art is relatively low in activity and selectivity. According to the technical scheme, through adoption of the catalyst for the ethylidene diacetate, SiO2, Al2O3 or a mixture of SiO2 and Al2O3 serves as a carrier of the catalyst, and active components comprise at least one kind of metal elements selected from iron series elements, alkali metal elements and at least one kind of metal elements selected from VB and VA groups, the technical problem is solved well; and the catalyst can be used for industrial production of vinyl acetate.

Owner:CHINA PETROLEUM & CHEM CORP +1

Synthetic method of ethylidene diacetate

ActiveCN103553913BOrganic-compounds/hydrides/coordination-complexes catalystsPreparation by carbon monoxide or formate reactionHydrogenIodide

The invention relates to a synthesis method for the carbonylation of methyl acetate to synthesize ethylene diacetate. It mainly solves the problem of using organic nitrogen or organic phosphorus as a promoter in the prior art to react methyl acetate through the carbonylation of methyl acetate to synthesize ethylene diacetate. The problems include low ester conversion rate, low yield of ethylene diacetate and low selectivity. This method uses methyl acetate, carbon monoxide and hydrogen as raw materials, and the solvent is acetic acid. The reaction temperature is 130~200°C, the reaction pressure is 2~10MPa, and the reaction time is 3~10h. The main method is to synthesize ethylene diacetate. The technical solution of using iron-based metals or their compounds as the catalyst, iodide as the cocatalyst and crown ether as the accelerator solves this problem well and can be used in the production of vinyl acetate.

Owner:CHINA PETROLEUM & CHEM CORP +1

Preparation method of diethylene acetate by methyl acetate

ActiveCN104447316BOrganic-compounds/hydrides/coordination-complexes catalystsPreparation by carbon monoxide or formate reactionOxygenEthyl acetate

The invention relates to a preparation method for preparing ethylidene diacetate from methyl acetate, which mainly solves the problems that the methyl acetate conversion rate is low and the ethylidene diacetate selectivity is low in the prior art. The invention adopts the following technical scheme: the preparation method for preparing ethylidene diacetate from methyl acetate comprises the following step: reacting MeOAc, CO and H2 used as raw materials in the presence of a supported catalyst, a cocatalyst and a promoter, thus generating the ethylidene diacetate, wherein the supported catalyst comprises a core-shell type support and a VIII metal or VIII metal compound supported on the support; the cocatalyst is an iodine-containing compound; the promoter is a nitrogen-oxygen organic substance or phosphorus-containing compound; and the core-shell type support has an amorphous aluminum oxide core and an amorphous silicon oxide shell. Thus, the technical scheme well solves the problems. The invention can be used for production of vinyl acetate.

Owner:CHINA PETROLEUM & CHEM CORP +1

Ethylidene diacetate catalyst and ethylidene diacetate synthesis method

ActiveCN105312057AHigh activityImprove stabilityPreparation by carbon monoxide or formate reactionMetal/metal-oxides/metal-hydroxide catalystsLow activityIndium

The invention relates to an ethylidene diacetate catalyst and an ethylidene diacetate synthesis method, and aims to solve the problems of low activity and selectivity of conventional ethylidene diacetate catalysts. The carrier of the provided catalyst includes SiO2, Al2O3, or a mixture of SiO2 and Al2O3, and the active component is composed of Cobalt and at least one selected from indium, vanadium, and praseodymium. The catalyst solves the problems mentioned above and can be applied to the industrial production of vinyl acetate.

Owner:CHINA PETROLEUM & CHEM CORP +1

Catalyst for preparing ethylidene diacetate

ActiveCN105478137AHigh activityImprove stabilityPreparation by carbon monoxide or formate reactionMetal/metal-oxides/metal-hydroxide catalystsAlkaline earth metalEthyl ester

The invention relates to a catalyst for preparing ethylidene diacetate. The catalyst is mainly used for solving the problem in the prior art that catalysts for ethylidene diacetate are relatively low in activity and selectivity. Through adopting the technical scheme that the catalyst for ethylidene diacetate adopts SiO2, Al2O3 or a mixture of SiO2 and Al2O3 as a carrier, and active ingredients comprise at least one element selected from ferrous elements, at least one element selected from metalloid elements and at least one metal element selected from IB and alkaline-earth metals, the technical problem is better solved, and the catalyst can be applied to the industrial production of vinyl acetate.

Owner:CHINA PETROLEUM & CHEM CORP +1

Catalyst used for production of ethylidene diacetate

ActiveCN105582937AHigh activityImprove stabilityPreparation by carbon monoxide or formate reactionMetal/metal-oxides/metal-hydroxide catalystsLow activityAlkaline earth metal

The invention relates to a catalyst used for production of ethylidene diacetate, and is mainly to solve the problem of low activity and selectivity of an ethylidene diacetate catalyst in the prior art. According to a technical scheme of the invention, the ethylidene diacetate catalyst uses SiO2, Al2O3 or a mixture of SiO2 and Al2O3 as a carrier, and an active component comprises at least one selected from the group consisting of iron series elements, lanthanum series elements, and at least one selected from the group consisting of group-IIB and alkaline-earth metals; thus, the above-mentioned technical problem is well solved, and the catalyst can be applied in industrial production of vinyl acetate.

Owner:CHINA PETROLEUM & CHEM CORP +1

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com