Rhodium metal complex-based mesoporous catalyst, as well as preparation method and application thereof

A technology of metal complexes and catalysts, which is applied in the field of heterogeneous mesoporous catalytic materials, can solve problems such as unfavorable industrialization promotion, difficulty in catalyst separation, and troubles for wide application, so as to reduce catalyst cost, high thermal stability, increase yield and selective effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

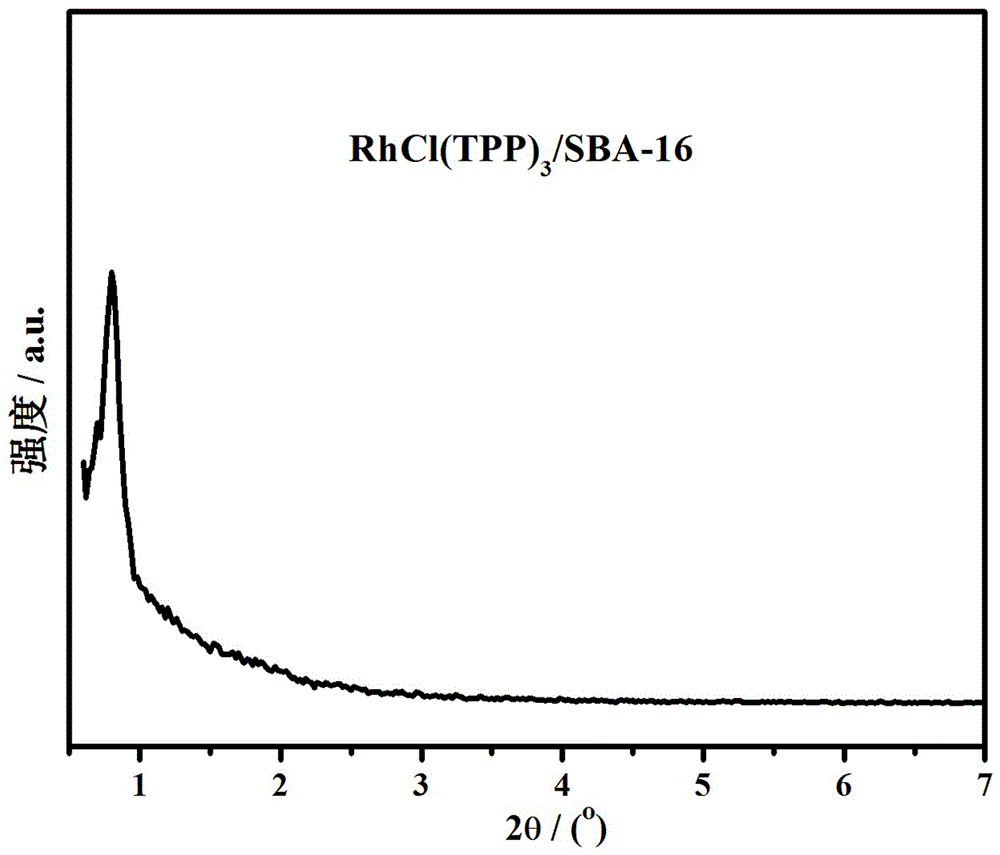

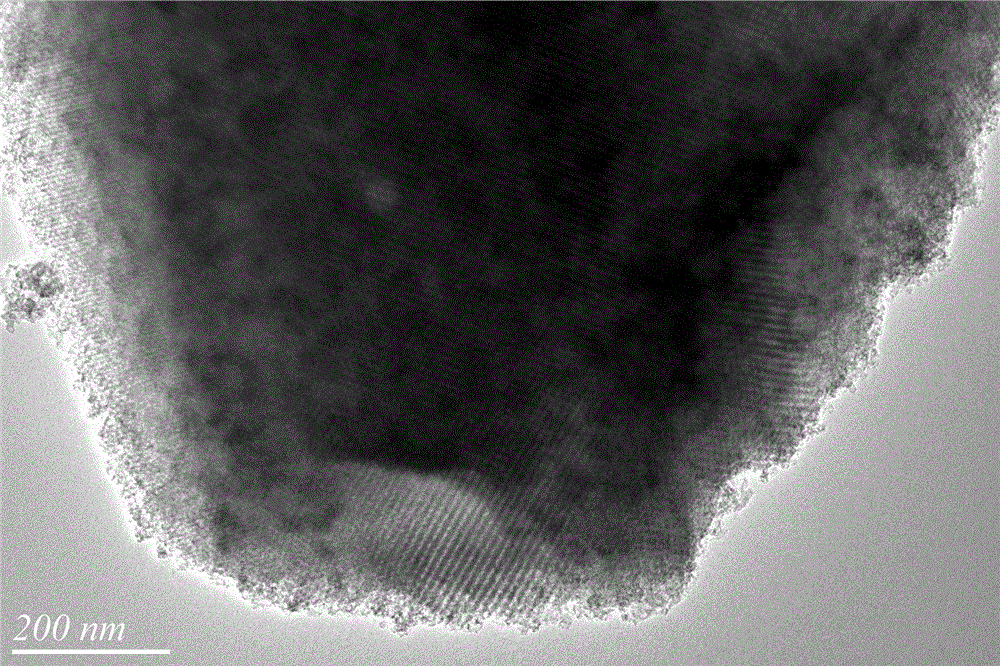

[0029] 1.0gF127 (EO 106 PO 70 EO 106 ) and 0.9g of potassium chloride were added to 40mL of 2.0mol / L hydrochloric acid solution, stirred at 40°C to dissolve the surfactant completely, then 4mL of tetraethyl orthosilicate was added dropwise to the system, stirred for 24h, and the milk The turbid liquid was put into a 100mL stainless steel reaction kettle with a Teflon liner, hydrothermally crystallized at 100°C for 48h, suction filtered, washed, dried, and roasted at 550°C for 6h to remove the organic template to obtain mesoporous SBA-16 Molecular sieve carrier.

[0030] Take 2.0g of SBA-16 molecular sieve and impregnate it in an equal volume of 9.76×10 -4 mol hydrated rhodium trichloride aqueous solution, ultrasonication for 2 hours, standing at room temperature for 24 hours, and drying to obtain a rhodium metal mesoporous catalyst (1g of SBA-16 carrier loaded with 0.48mmol of rhodium metal active components).

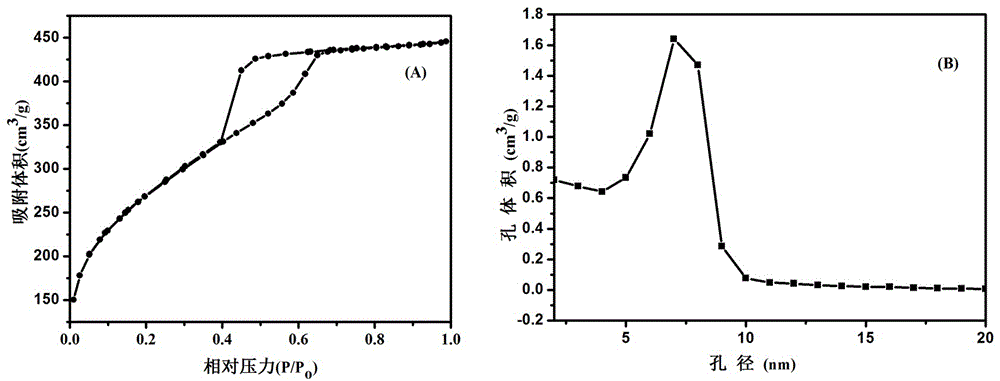

[0031] Take 2.2g of rhodium metal mesoporous catalyst, mix wi...

Embodiment 2

[0037] The preparation of the mesoporous catalyst is the same as in Example 1, except that the loading amount of the rhodium metal active component is 0.36 mmol / g, and the ligand material is changed to tributylphosphine.

[0038] The mesoporous catalyst prepared in this example has a highly ordered three-dimensional cubic mesoporous structure, and the mesopore diameter, specific surface area and pore volume are 5.7nm and 698m 2 / g and 0.43cm 3 / g, rhodium metal complex loading 1.8%.

[0039] Carry out methyl acetate carbonylation reaction synthetic ethylene diacetate test according to embodiment 1, the result shows methyl acetate conversion rate 70.1%, ethylene diacetate selectivity 66.3%.

Embodiment 3

[0041] The preparation of the mesoporous catalyst was the same as in Example 1, except that the loading amount of the rhodium metal active component was 0.4 mmol / g, and the solvent of the ligand material was changed to ethanol.

[0042] The mesoporous catalyst prepared in this example has a highly ordered three-dimensional cubic mesoporous structure, and the mesopore diameter, specific surface area and pore volume are 5.8nm and 665m 2 / g and 0.42cm 3 / g, rhodium metal complex loading 2.04%.

[0043] Carry out methyl acetate carbonylation reaction synthetic ethylene diacetate test according to embodiment 1, the result shows methyl acetate conversion rate 73.4%, ethylene diacetate selectivity 66.7%.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Aperture | aaaaa | aaaaa |

| Pore volume | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com