Catalyst used in ethylidene diacetate preparation

A technology of ethylene diacetate and catalyst, applied in physical/chemical process catalyst, carbon monoxide or formate reaction preparation, metal/metal oxide/metal hydroxide catalyst, etc., can solve the problem of ethylene diacetate yield. problems such as low yield and low selectivity, to achieve the effect of improving yield and selectivity, improving activity and stability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

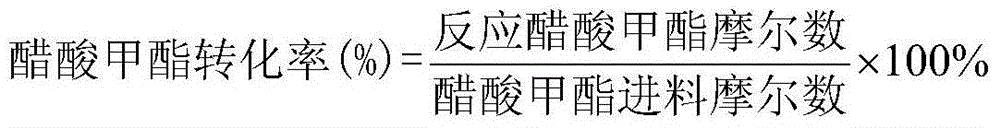

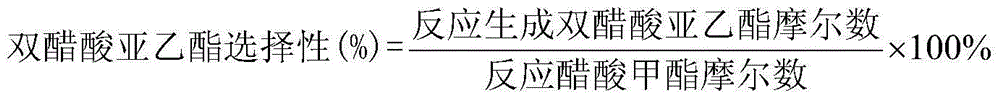

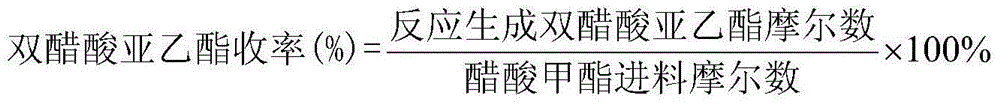

Examples

Embodiment 1

[0029] Preparation of catalyst: CoCl containing 8.30gCo, 3.20gCe and 3.50gBi 2 ·6H 2 O, CeCl 3 ·6H 2 O and ammonium bismuth citrate (Bi(NH 3 ) 2 C 6 h 7 o 7 ·H 2 O) fully mixed and dissolved in pure water to obtain 400ml of impregnation solution, and the specific surface of 1.0L was 165m 2 / g, spherical SiO with a pore volume of 0.95 and a diameter of 5.6mm 2 The carrier was immersed in the above impregnating solution, left to stand for 2 hours and dried at 100° C. to obtain the catalyst. The Co content of the catalyst analyzed by ICP is 8.30g / L, the Ce content is 3.20g / L, and the Bi content is 3.50g / L.

[0030] Synthesis of diethylene acetate: Add 1.0mol acetic acid, 0.05mol catalyst, 0.10mol methyl iodide and 0.45mol methyl acetate into a 500ml titanium reactor, first use argon to discharge the air in the kettle and then pressurize to 2.0MPa, Then feed carbon monoxide and hydrogen until the pressure is 7.5MPa, increase the stirring speed to 1200rpm, while stirring...

Embodiment 2

[0034] Preparation of catalyst: CoCl containing 8.30gCo, 3.20gCe and 3.50gBe 2 ·6H 2 O, CeCl 3 ·6H 2 O and BeCl2 Fully mix and dissolve in pure water to obtain 400ml of impregnation solution, and the specific surface of 1.0L is 165m 2 / g, spherical SiO with a pore volume of 0.95 and a diameter of 5.6mm 2 The carrier was immersed in the above impregnating solution, left to stand for 2 hours and dried at 100° C. to obtain the catalyst. The Co content of the catalyst analyzed by ICP was 8.30g / L, the Ce content was 3.20g / L, and the Be content was 3.50g / L.

[0035] Synthesis of diethylene acetate: Add 1.0mol acetic acid, 0.05mol catalyst, 0.10mol methyl iodide and 0.45mol methyl acetate into a 500ml titanium reactor, first use argon to discharge the air in the kettle and then pressurize to 2.0MPa, Then feed carbon monoxide and hydrogen until the pressure is 7.5MPa, increase the stirring speed to 1200rpm, while stirring and heating to the reaction temperature, control the react...

Embodiment 3

[0046] Preparation of catalyst: NiCl containing 7.00gNi, 1.00gSc and 1.00gBi 2 ·6H 2 O, Sc(OAc) 3 ·6H 2 O and Bi 2 (SO 4 ) 3 Fully mixed and dissolved in hydrochloric acid with a concentration of 8wt%, to obtain 400ml of impregnation solution, and the specific surface of 1.0L was 150m 2 / g, spherical Al with a pore volume of 0.90 and a diameter of 5.6mm 2 o 3 The carrier was immersed in the above impregnating solution, left to stand for 2 hours and dried at 80° C. to obtain the catalyst. The Ni content of the catalyst analyzed by ICP was 7.00g / L, the Sc content was 1.00g / L, and the Bi content was 1.00g / L.

[0047] Synthesis of diethylene acetate: Add 1.0mol acetic acid, 0.05mol catalyst, 0.10mol methyl iodide and 0.45mol methyl acetate into a 500ml titanium reactor, first use argon to discharge the air in the kettle and then pressurize to 2.0MPa, Then feed carbon monoxide and hydrogen until the pressure is 7.5MPa, increase the stirring speed to 1200rpm, while stirring...

PUM

| Property | Measurement | Unit |

|---|---|---|

| specific surface area | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

| specific surface area | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com