Preparation method for preparing ethylidene diacetate from methyl acetate

A technology of diethylene acetate and methyl acetate, applied in the direction of carbon monoxide or formate reaction preparation, chemical instruments and methods, organic compound/hydride/coordination complex catalyst, etc., can solve the problem of diacetate Solve the problems of low selectivity and low conversion rate of methyl acetate to achieve the effect of improving selectivity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

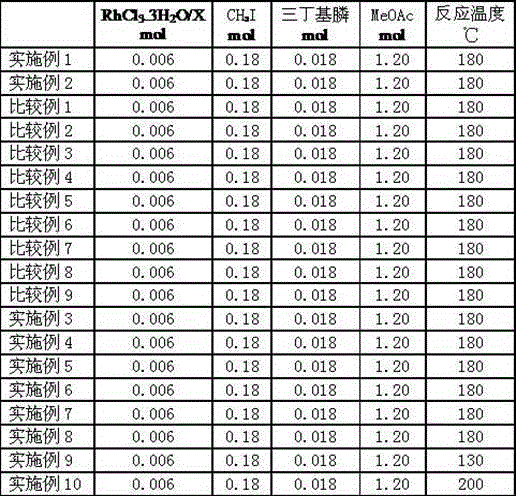

Examples

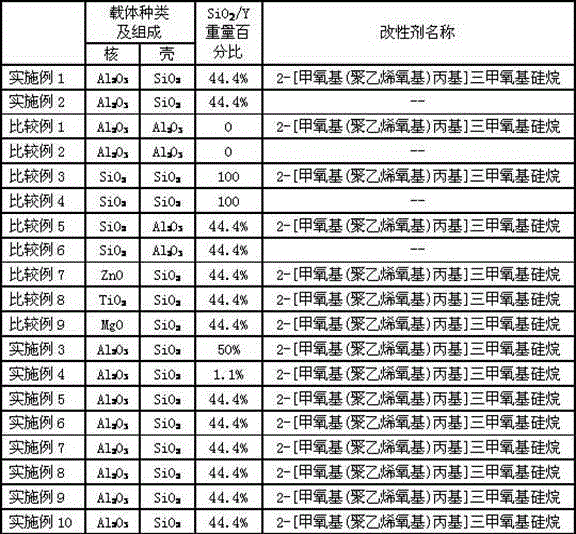

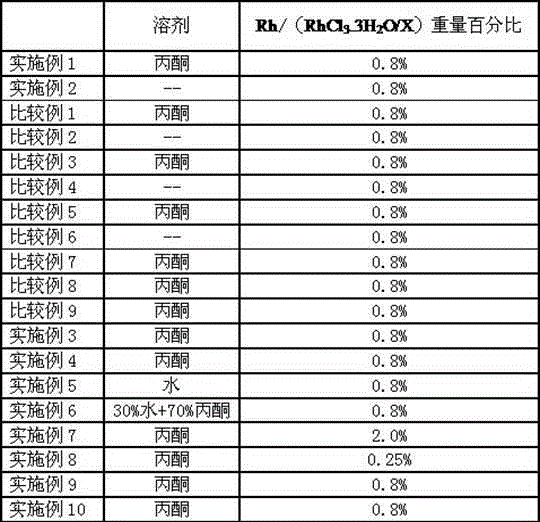

Embodiment 1

[0016] Preparation of core-shell carrier: will contain 4g SiO 2 200ml of acidified sodium silicate solution was evenly added dropwise in 5gAl 2 o 3 After 20 minutes, it was filtered, placed under ventilated conditions for 1 hour, dried at 110°C for 2 hours, and then calcined at 450°C for 4 hours to obtain a core-shell carrier (Y), in which the amorphous silica shell accounted for the weight of the carrier (Y) 44.4% of the total.

[0017] Modification of the carrier: 30g of 2-[methoxy(polyethyleneoxy)propyl]trimethoxysilane (CAS No.65994-07-2, English name 2-[Methoxy(polyethyleneoxy)propyl]- trimethoxy silane) in acetone solution, sprayed on the core-shell carrier (Y), stirred, filtered, washed and dried to obtain the modified core-shell carrier (X).

[0018] Preparation of supported catalyst: weigh 33g carrier X, 0.75gRhCl 3 .3H 2 O, 200mlH 2 O was mixed thoroughly, and then dried at 100 °C to obtain a supported catalyst RhCl containing 0.8% (weight percent) Rh 3 .3H ...

Embodiment 2

[0023] for 【Example 1】 comparative example.

[0024] Preparation of core-shell carrier: will contain 4g SiO 2 200ml of acidified sodium silicate solution was evenly added dropwise in 5gAl 2 o 3 After 20 minutes, it was filtered, placed under ventilated conditions for 1 hour, dried at 110°C for 2 hours, and then calcined at 450°C for 4 hours to obtain a core-shell carrier (X), in which the amorphous silica shell accounted for the weight of the carrier (X) 44.4% of the total.

[0025] Preparation of supported catalyst: weigh 33g X carrier, 0.75gRhCl 3 .3H 2 O, 200mlH 2 O was mixed thoroughly, and then dried at 100 °C to obtain a supported catalyst RhCl containing 0.8% (weight percent) Rh 3 .3H 2 O / X.

[0026] Synthesis of diethylene acetate: 0.006molRhCl 3 .3H 2 O / X, 0.18molCH 3 I. Add 0.018mol tributylphosphine and 1.20mol MeOAc into a 2-liter titanium reactor that has replaced the air with argon in advance, and then feed carbon monoxide and hydrogen so that the mo...

Embodiment 3

[0096] Preparation of core-shell carrier: will contain 5g SiO 2 200ml of acidified sodium silicate solution was evenly added dropwise in 5gAl 2 o 3 After 20 minutes, it was filtered, placed under ventilated conditions for 1 hour, dried at 110°C for 2 hours, and then calcined at 450°C for 4 hours to obtain a core-shell carrier (Y), in which the amorphous silica shell accounted for the weight of the carrier (Y) 50.0% of.

[0097] Modification of the carrier: 30g of 2-[methoxy(polyethyleneoxy)propyl]trimethoxysilane (CAS No.65994-07-2, English name 2-[Methoxy(polyethyleneoxy)propyl]- trimethoxy silane) in acetone solution, sprayed on the core-shell carrier (Y), stirred, filtered, washed and dried to obtain the modified core-shell carrier (X).

[0098] Preparation of supported catalyst: weigh 33g carrier X, 0.75gRhCl 3 .3H 2 O, 200mlH 2 O was mixed thoroughly, and then dried at 100 °C to obtain a supported catalyst RhCl containing 0.8% (weight percent) Rh 3 .3H 2 O / X.

...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com