Synthetic method of ethylidene diacetate

A technique for the synthesis of diethylene acetate, applied in chemical instruments and methods, carbon monoxide or formate reaction preparation, organic compound/hydride/coordination complex catalyst, etc., can solve the problem of low conversion rate of methyl acetate , low selectivity, low yield of diethylene acetate, etc., to improve activity and stability, increase conversion rate, and reduce loss

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

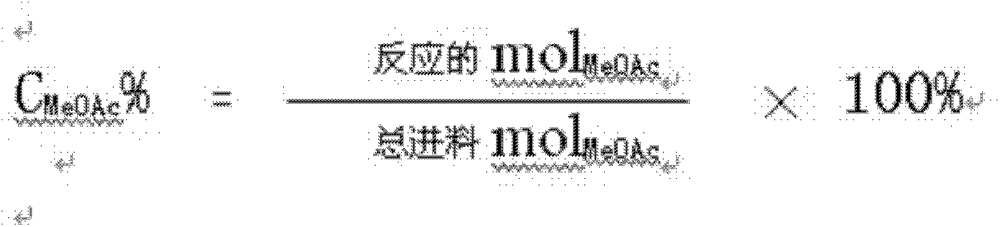

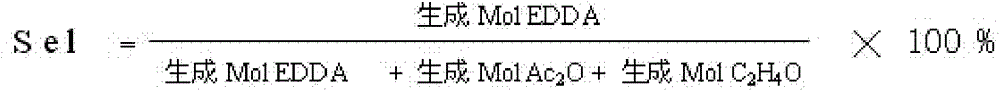

Method used

Image

Examples

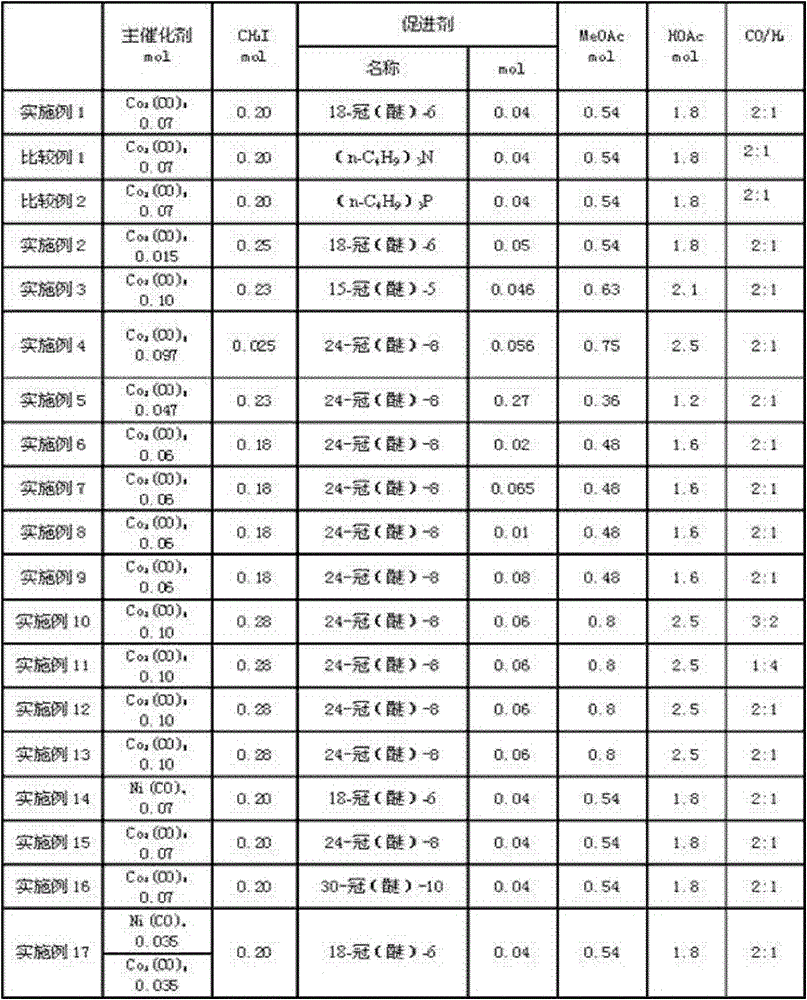

Embodiment 1

[0016] Synthesis of diethylene acetate: 1.8mol acetic acid, 0.07mol Co 2 (CO) 8 , 0.20molCH 3 1, 0.04mol18-crown (ether)-6 and 0.54mol methyl acetate are added in the titanium material reaction kettle, first discharge the air in the kettle with argon and pressurize to 2.0MPa, then feed carbon monoxide and hydrogen until the pressure is 8.7MPa, Increase the stirring speed to 1500rpm, while stirring and heating to the reaction temperature, control the reaction temperature to 183°C, the molar ratio of carbon monoxide and hydrogen to 2:1, continue the reaction for 8.5h, then stop the reaction.

[0017] Product analysis: the reaction mixture obtained by the above reaction is cooled, decompressed, separated, and the liquid phase is analyzed by gas chromatography-mass spectrometry (GC-MASS) to obtain 4.07% ethylene diacetate, 0.72% acetic anhydride, acetaldehyde 0.27%, 85.88% acetic acid.

[0018] The calculated yield of ethylene diacetate is 58.68%, and the selectivity is 85.88%....

Embodiment 2

[0028] 1.8mol acetic acid, 0.015mol Co 2 (CO) 8 , 0.25molCH 3 1, 0.05mol15-crown (ether)-5 and 0.54mol methyl acetate are added in the titanium material reaction kettle, first use argon gas to discharge the air in the kettle and pressurize to 2.0MPa, then feed carbon monoxide and hydrogen until the pressure is 8.7MPa, Increase the stirring speed to 1500rpm, while stirring and heating to the reaction temperature, control the reaction temperature to 183°C, the molar ratio of carbon monoxide and hydrogen to 2:1, continue the reaction for 8.5h, then stop the reaction.

[0029] Product is through analysis and calculation, and for convenience of illustration and comparison, the yield and the selectivity of reaction condition, each material feed amount, and diacetate are listed in table 1 and table 2 respectively.

Embodiment 3

[0031] 2.1mol acetic acid, 0.10mol Co 2 (CO) 8 , 0.23molCH 3 1, 0.046mol15-crown (ether)-5 and 0.63mol methyl acetate are added in the titanium material reaction kettle, first discharge the air in the kettle with argon and pressurize to 2.0MPa, then feed carbon monoxide and hydrogen until the pressure is 8.7MPa, Increase the stirring speed to 1500rpm, while stirring and heating to the reaction temperature, control the reaction temperature to 183°C, the molar ratio of carbon monoxide and hydrogen to 2:1, continue the reaction for 8.5h, then stop the reaction.

[0032] Product is through analysis and calculation, and for convenience of illustration and comparison, the yield and the selectivity of reaction condition, each material feed amount, and diacetate are listed in table 1 and table 2 respectively.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com