Method and device for preparing vinyl acetate through reactive distillation

A vinyl acetate and reactive distillation technology, which is applied in the preparation of carboxylic acid esters, chemical instruments and methods, and the preparation of organic compounds, can solve the problems of not improving the EDA conversion rate and energy consumption of equipment, and shorten the reaction residence time. Time, improve yield and purity, reduce the effect of polymerization side reaction chance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

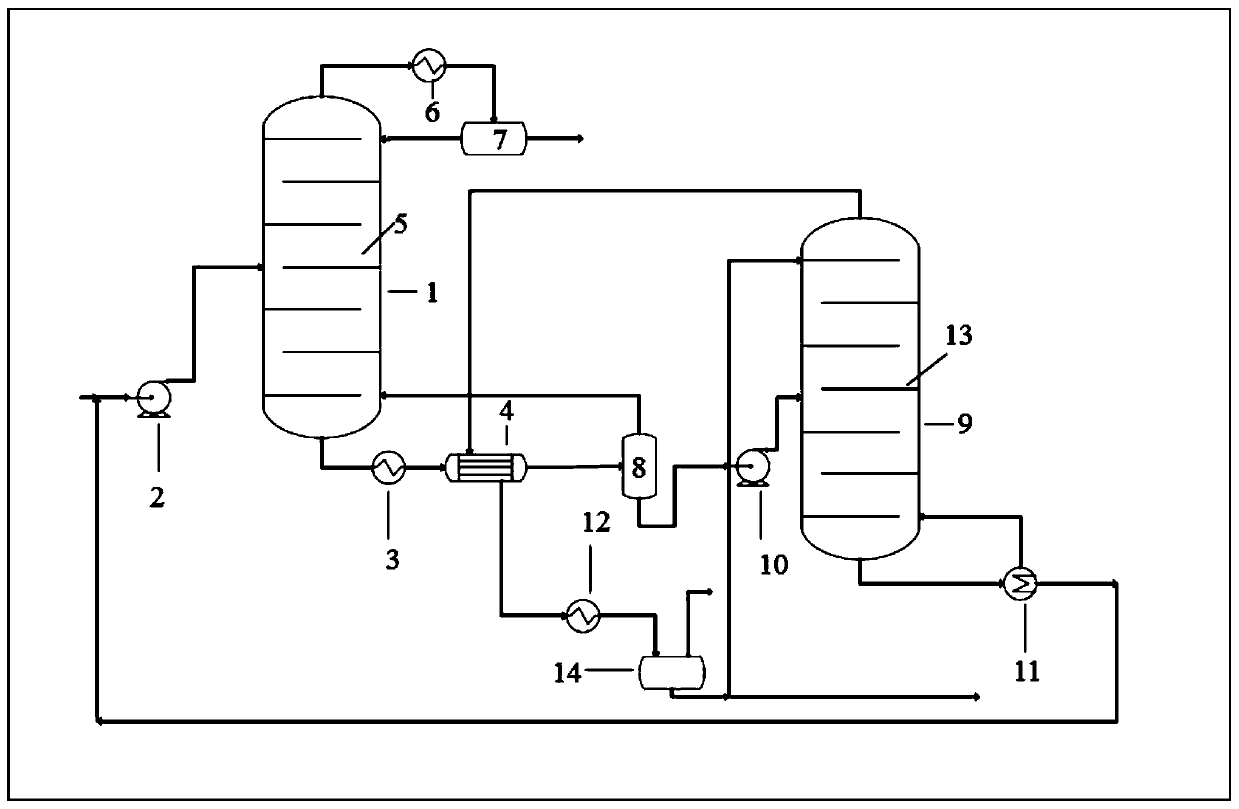

Method used

Image

Examples

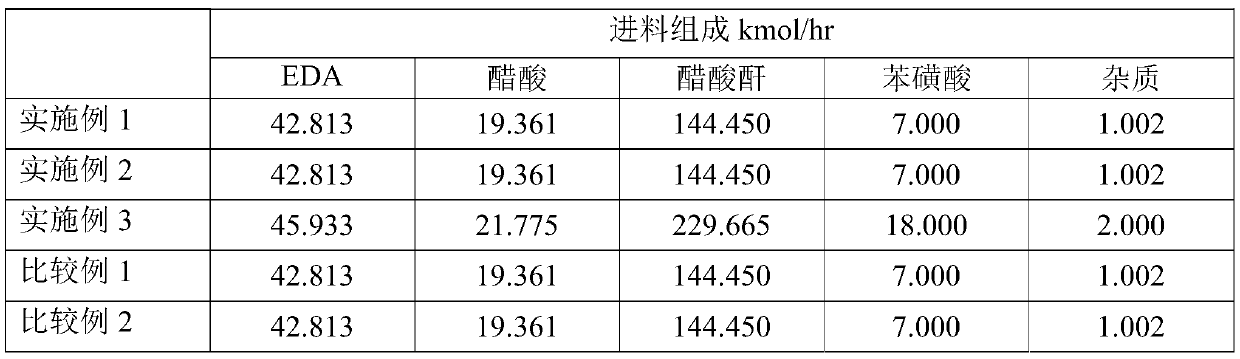

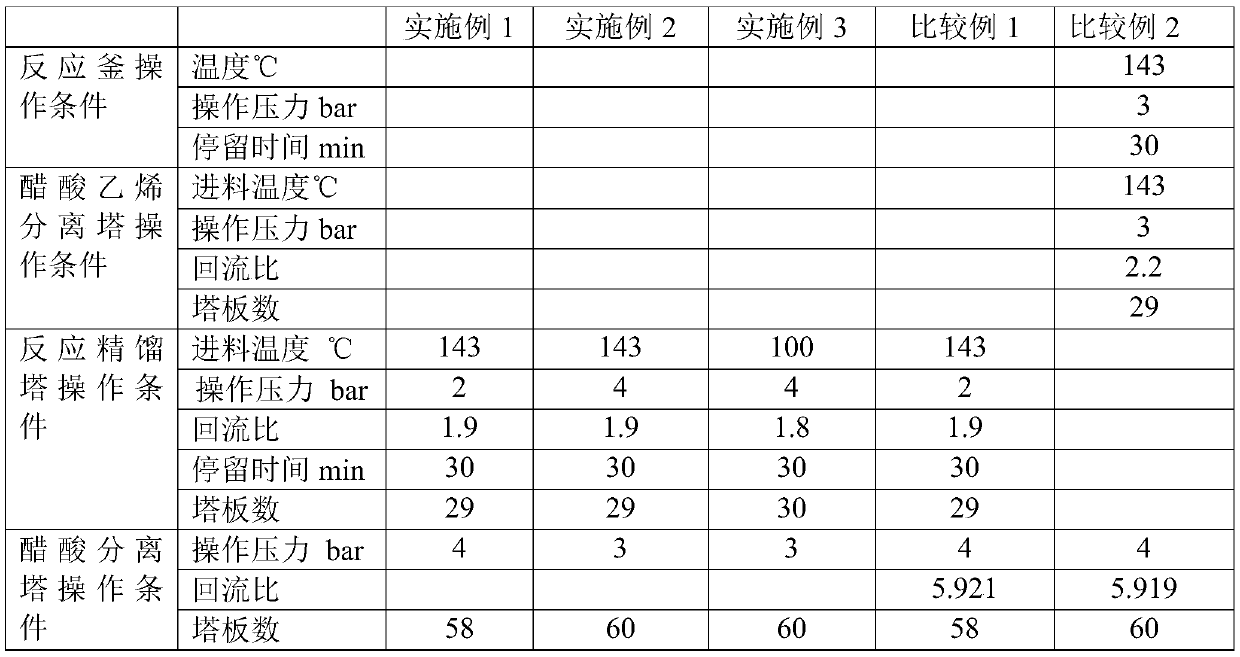

Embodiment 1

[0048] Mix the preliminarily purified EDA raw material liquid with benzenesulfonic acid and acetic anhydride in proportion and then feed it into the reactive distillation column. 144.450kmol / hr, benzenesulfonic acid 7.000kmol / hr. The feed temperature of the reactive distillation tower is 143°C, the tower operating pressure is 2bar, the tower top temperature is 94.556°C, the tower bottom temperature is 162.93°C, the reflux ratio is 1.9, the number of trays is 29, and the feed plate is the 10th Feed above the block tray, and the reaction residence time is 30min. After reactive distillation, the tower top obtains a VAC product with a purity of 99.97% (in terms of mass fraction). After heat exchange, the gas-phase material at the top of the separation tower enters the adiabatic flash tank to separate the gas-liquid two-phase, and the liquid-phase product enters the acetic acid separation tower. The feed temperature of the acetic acid separation tower is 162.96 ℃, and the tower op...

Embodiment 2

[0050] Mix the preliminarily purified EDA raw material liquid with benzenesulfonic acid and acetic anhydride in proportion and then feed it into the reactive distillation column. 144.450kmol / hr, benzenesulfonic acid 7.000kmol / hr. The feed temperature of the reactive distillation tower is 143°C, the operating pressure of the tower is 4bar, the temperature of the top of the tower is 120.51°C, the temperature of the bottom of the tower is 186.15°C, the reflux ratio is 1.9, the number of trays is 29, and the feed plate is the 10th Feed above the block tray, and the reaction residence time is 30min. After reactive distillation, the tower top obtains a VAC product with a purity of 99.97% (in terms of mass fraction). After heat exchange, the gas-phase material at the top of the separation tower enters the adiabatic flash tank to separate the gas-liquid two-phase, and the liquid-phase product enters the acetic acid separation tower. The feed temperature of acetic acid separation towe...

Embodiment 3

[0052] Mix the preliminarily purified EDA raw material liquid with benzenesulfonic acid and acetic anhydride in proportion and then add it to the reactive distillation column. 229.665kmol / hr, benzenesulfonic acid 18.000kmol / hr. The feed temperature of the reactive distillation column is 100°C, the tower operating pressure is 4bar, the tower top temperature is 120.498°C, the tower bottom temperature is 188.9°C, the reflux ratio is 1.8, the number of trays is 30, and the feed plate is the 10th Feed above the block tray, and the reaction residence time is 30min. After reactive distillation, the tower top obtains a VAC product with a purity of 99.98% (in terms of mass fraction). After heat exchange, the gas-phase material at the top of the separation tower enters the adiabatic flash tank to separate the gas-liquid two-phase, and the liquid-phase product enters the acetic acid separation tower. The feed temperature of acetic acid separation tower is 188.9 ℃, and tower operation pr...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com