Process improvement for producing epichlorohydrin by using glycerin method dichloropropanol as raw material

A technology of epichlorohydrin and dichloropropanol, applied in the direction of organic chemistry, etc., can solve the problems of increasing the cost of wastewater treatment, increasing the TOC of brine, and decreasing the yield of ECH, and achieves short reaction residence time, increased reaction speed, and reduced The effect of TOC

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

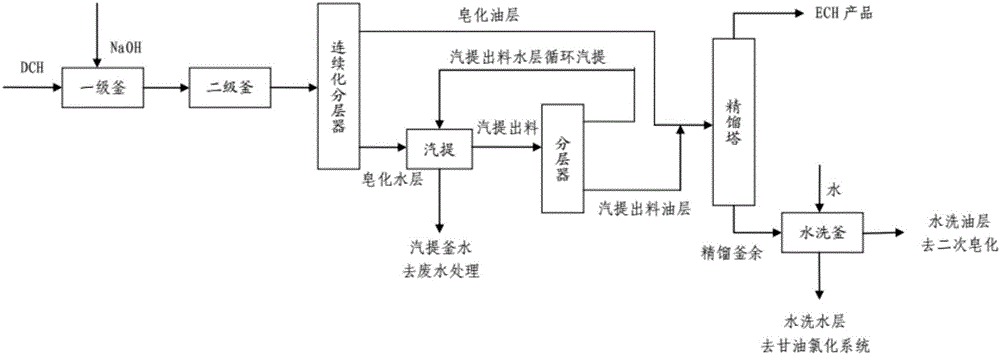

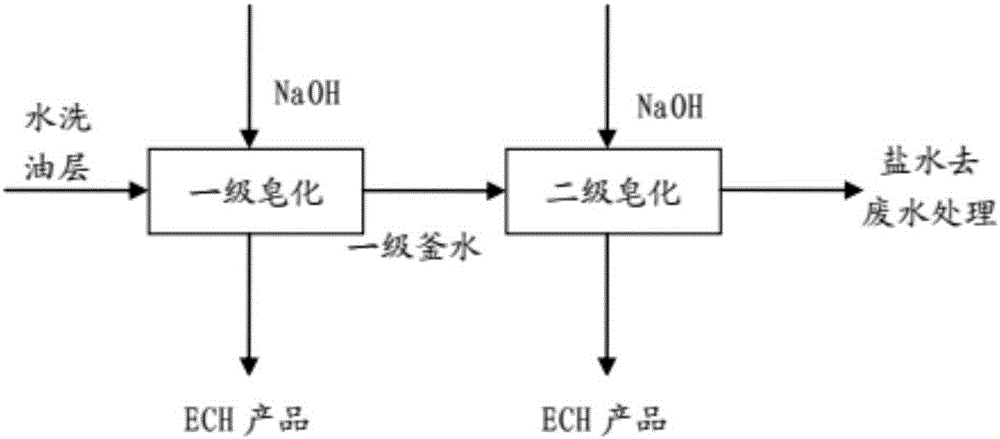

[0028] 1. One-time atmospheric pressure layered saponification

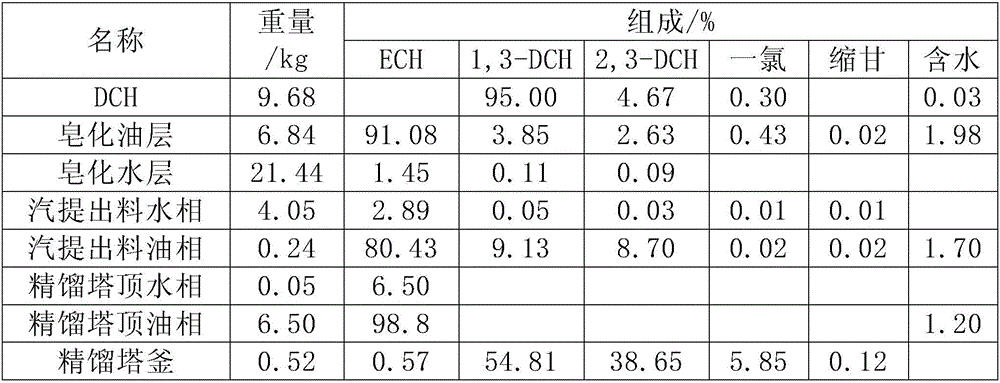

[0029] Adopt two-stage continuous tank saponification under normal pressure, DCH (content 99.67%) and NaOH (15.11%) are continuously fed into the first-level tank, the flow rates are 0.645kg / h and 1.24kg / h respectively, and overflow to the second-level Still, the reaction residence time is 10 minutes, the temperature is 40 ° C, and it runs for 15 hours in total. It enters the stratifier and continuously separates 6.84 kg of oil phase and 21.44 kg of water phase. The saponified water layer was stripped under the conditions of 40-50°C and -0.1MPa, a total of 4.29kg was evaporated, and 4.05kg of the water phase and 0.24kg of the oil phase were separated; Distillation, reflux ratio R=1, collect 6.55kg of distillate at 116-118°C, separate out 0.05kg of water phase and 6.5kg of oil phase, and 0.52kg of residue in the kettle; from one saponification to the end of rectification, the conversion rate of DCH is 94.9%, and t...

Embodiment 2

[0038] 1. One-time atmospheric pressure layered saponification

[0039] Adopt two-stage continuous tank saponification under normal pressure, DCH (content 99.67%) and NaOH (18.5%) are continuously fed into the first-level tank, the flow rates are 0.645kg / h and 0.97kg / h respectively, and overflow to the second-level Still, the reaction residence time is 5 minutes, the temperature is 40 ° C, and it runs for 15 hours in total. It enters the stratifier to separate 6.95 kg of oil phase and 17.28 kg of water phase. The saponified water layer was stripped under the conditions of 40-50°C and -0.1MPa, a total of 3.19kg was distilled out, and 3.0kg of water phase and 0.19kg of oil phase were separated; the saponified oil layer and the stripped oil layer were combined, and a 1m glass packed column was used to fine-tune Distillation, reflux ratio R=1, collect 6.50kg of distillate at 116-118°C, separate out 0.03kg of water phase and 6.46kg of oil phase, and 0.67kg of residue in the kettle;...

Embodiment 3

[0048] 1. One-time atmospheric pressure layered saponification

[0049] 7.5kgDCH (content 99.67%) was dropped into a 20L kettle, stirred and heated to 40°C, and 15% NaOH aqueous solution was started to be added dropwise, the reaction temperature was maintained at 40°C, and the dropwise addition time was 5 minutes. Add 14.68kg of liquid caustic soda dropwise; after the reaction, pour it into a separatory funnel, let it stand for stratification, separate the upper layer into 5.24kg of oil phase, and the lower layer into 16.94kg of water phase; strip the water phase under negative pressure of -0.095MPa, 3.35kg is produced, oil and water are separated in the production liquid, and 3.15kg of the water phase is applied to the next batch of steam stripping. The 0.2kg of the oil phase is combined with the saponified oil layer and rectified under normal pressure. layer, the unreacted DCH collected in the tower kettle is 0.36kg. From the primary saponification to the end of rectificati...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com