Preparation method of ethylidene diacetate

A technology of ethylene diacetate and acetic acid is applied in the field of preparation of synthesizing ethylene diacetate from methyl acetate, and can solve the problem of low yield of ethylene diacetate, low selectivity, low conversion rate of methyl acetate, etc. problem, to achieve the effect of improving conversion rate and improving activity and stability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

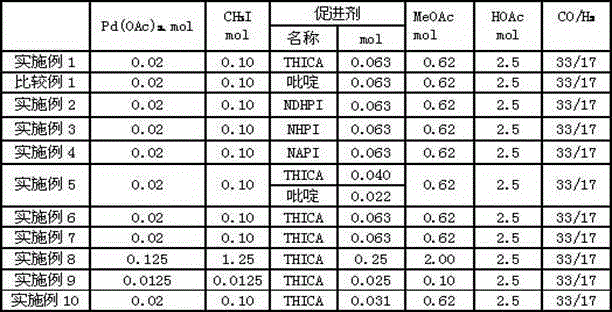

Embodiment 1

[0019] Synthesis of diethylene acetate: 2.5mol acetic acid, 0.02molPd(OAc) 2 , 0.1molCH 3 I. Add 0.063mol N, N', N"-trihydroxyisocyanuric acid (formula II, THICA) and 0.62mol methyl acetate into the titanium reactor, first use argon to discharge the air in the reactor and then pressurize to 2.0MPa, Then feed carbon monoxide and hydrogen until the pressure is 7.5 MPa, increase the stirring speed to 1200rpm, while stirring and heating to the reaction temperature, control the reaction temperature to 178°C, the molar ratio of carbon monoxide to hydrogen is 33:17, continue the reaction for 7 hours, stop the reaction .

[0020] Product analysis: The reaction mixture obtained from the above reaction was cooled, decompressed, and separated, and the liquid phase was analyzed by gas chromatography-mass spectrometry (GC-MASS).

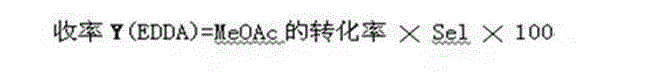

[0021] And calculate the yield and the selectivity of synthesizing ethylene diacetate by following formula:

[0022]

[0023]

[0024] The conversion ra...

Embodiment 2

[0031] Synthesis of diethylene acetate: 2.5mol acetic acid, 0.02molPd(OAc) 2 , 0.1molCH 3 I. Add 0.063mol N, N'-dihydroxypyromellitic acid imide (formula V, NDHPI) and 0.62mol methyl acetate into the titanium reactor, first use argon to discharge the air in the reactor and then pressurize to 2.0MPa , then feed carbon monoxide and hydrogen until the pressure is 7.5 MPa, increase the stirring speed to 1200rpm, at the same time stir and heat up to the reaction temperature, control the reaction temperature to 178°C, the molar ratio of carbon monoxide and hydrogen is 33:17, continue the reaction for 7h, stop reaction.

[0032] Product analysis: The reaction mixture obtained from the above reaction was cooled, decompressed, and separated, and the liquid phase was analyzed by gas chromatography-mass spectrometry (GC-MASS).

[0033] The conversion rate of methyl acetate was calculated to be 70.82%, the yield of ethylene diacetate was 60.09%, and the selectivity was 84.85%. For ease...

Embodiment 3

[0035] Synthesis of diethylene acetate: 2.5mol acetic acid, 0.02molPd(OAc) 2 , 0.1molCH 3 I. Add 0.063mol N-hydroxyphthalimide (Formula III, NHPI) and 0.62mol methyl acetate into the titanium reactor, first use argon to discharge the air in the kettle, then pressurize to 2.0MPa, and then pass Add carbon monoxide and hydrogen until the pressure is 7.5 MPa, increase the stirring speed to 1200rpm, stir and heat to the reaction temperature at the same time, control the reaction temperature to 178°C, the molar ratio of carbon monoxide to hydrogen is 33:17, continue the reaction for 7 hours, then stop the reaction.

[0036] Product analysis: The reaction mixture obtained from the above reaction was cooled, decompressed, and separated, and the liquid phase was analyzed by gas chromatography-mass spectrometry (GC-MASS).

[0037] The conversion rate of methyl acetate was calculated to be 70.54%, the yield of ethylene diacetate was 60.07%, and the selectivity was 85.16%. For ease of d...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com