Diethylene acetate method vinyl acetate catalyst and vinyl acetate synthesis method

A technology of diethylene acetate and method vinyl acetate, which is applied in the field of diethylene acetate method vinyl acetate catalyst and vinyl acetate synthesis, can solve the problems of low conversion rate of diethylene acetate and low selectivity of vinyl acetate, etc. achieve the effect of increasing the conversion rate

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

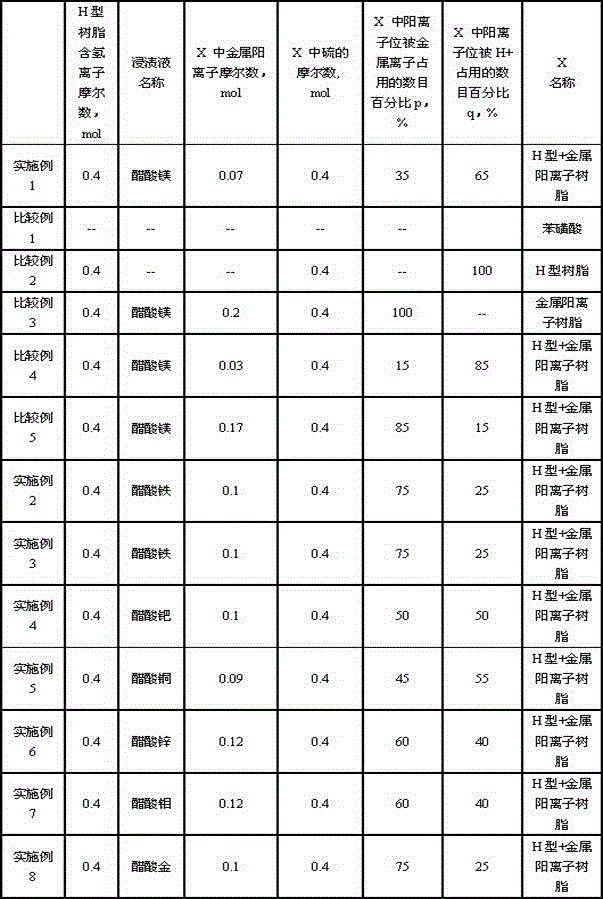

Embodiment 1

[0017] Preparation of catalysts containing hydrogen ions and metal cation exchange resins: Weigh 180 g of H-type macroporous cation exchange resins containing 0.4 mol of hydrogen ions after drying at 60° C. and put them into a beaker. 2+ The resin in the beaker was impregnated with 220ml of magnesium acetate solution, stirred for 3 hours, and then dried at 60°C for 24 hours to obtain an exchange resin containing Mg. Then use H-type cation exchange resin and Mg-containing exchange resin to mix to obtain the catalyst (X) containing hydrogen and Mg-containing cation exchange resin. The obtained resin is calculated by X-fluorescence analysis. The number of moles of sulfur is 0.4mol, and the number of moles of Mg It is 0.07mol, calculated p=35%, q=65%.

[0018] The synthesis of vinyl acetate: 9.5g (X), 0.8mol acetic anhydride, 0.2mol diethylene acetate (that is, the molar ratio of solvent to diacetate is 4, the catalyst accounts for the total weight percentage of diacetate and solv...

Embodiment 2

[0054] Preparation of catalysts containing hydrogen ions and metal cation exchange resins: Weigh 180 g of H-type macroporous cation exchange resins containing 0.4 mol of hydrogen ions after drying at 60° C. 3+ The resin in the beaker was impregnated with 220ml of ferric acetate solution, stirred for 3 hours, and then dried at 60°C for 24 hours to obtain an exchange resin containing Fe. Then mix the H-type cation exchange resin with the Fe-containing exchange resin to obtain the catalyst (X) containing hydrogen and Fe-containing cation exchange resin, and the obtained resin is calculated by X-fluorescence analysis. The mole number of sulfur is 0.4mol, and the mole number of Fe is It is 0.1mol, calculated p=75%, q=25%.

[0055] The synthesis of vinyl acetate: 9.5g (X), 0.8mol acetic anhydride, 0.2mol diethylene acetate (that is, the molar ratio of solvent to diacetate is 4, the catalyst accounts for the total weight percentage of diacetate and solvent 8.6%) into a 1-liter react...

Embodiment 3

[0059] Preparation of catalysts containing hydrogen ions and metal cation exchange resins: Weigh 180 g of H-type macroporous cation exchange resins containing 0.4 mol of hydrogen ions after drying at 60° C. 3+ The resin in the beaker was impregnated with 220ml of ferric acetate solution, stirred for 3 hours, and then dried at 60°C for 24 hours to obtain an exchange resin containing Fe. Then mix the H-type cation exchange resin with the Fe-containing exchange resin to obtain the catalyst (X) containing hydrogen and Fe-containing cation exchange resin, and the obtained resin is calculated by X-fluorescence analysis. The mole number of sulfur is 0.4mol, and the mole number of Fe is It is 0.1mol, calculated p=75%, q=25%.

[0060] The synthesis of vinyl acetate: 2.6g (X), 0.2mol acetic anhydride, 0.2mol diethylene acetate (that is, the molar ratio of solvent to diacetate is 1, the catalyst accounts for the total weight percentage of diacetate and solvent 5.2%) into a 1-liter react...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com