Gas distributor and vinyl acetate synthesis reactor comprising the same

A synthesis reactor and gas distributor technology, applied in chemical instruments and methods, preparation of carboxylic acid esters, preparation of organic compounds, etc., can solve problems such as not being able to meet the high-precision control requirements of synthesis reactors, and achieve improved reaction control Accuracy, simplified structure, and improved reliability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

example 1

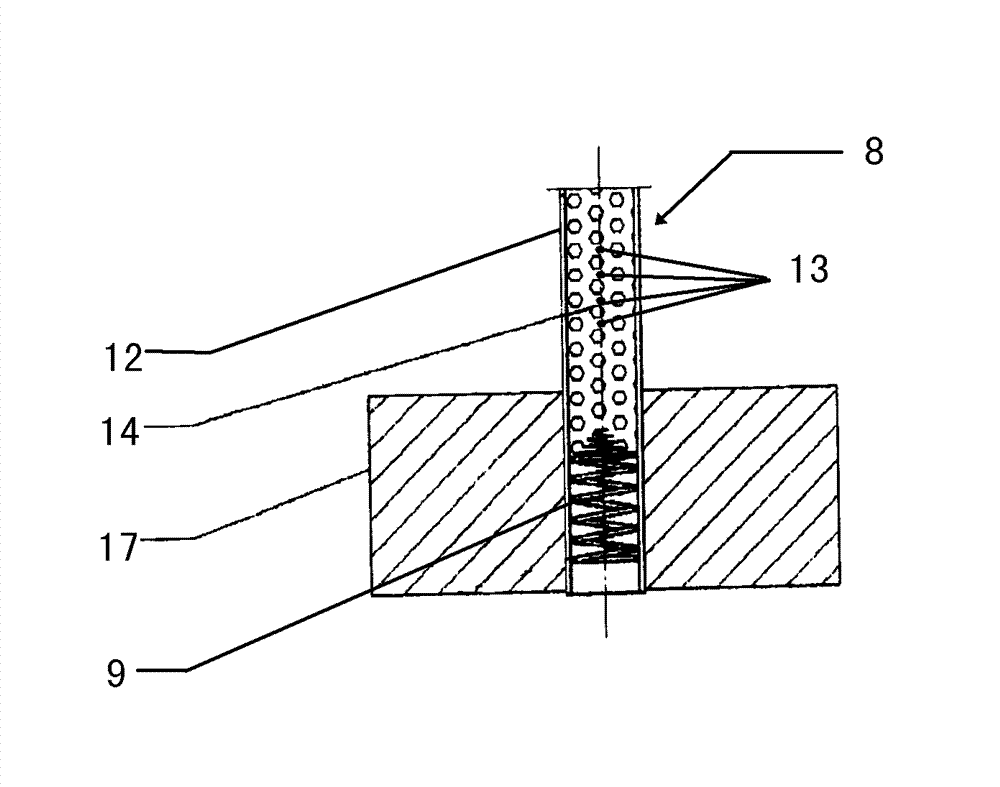

[0047] as per figure 1 The structure shown allows for the fabrication and installation of the in-reactor gas distributor according to the invention. The specific structural parameters are as follows, the diameter of the reactor is 5000 mm, the diameter of the gas inlet is 600 mm, the diameter of the cylindrical shell of the gas distributor is 900 mm, the diameter of the spherical head of the gas distributor is the same, and the diameter of the cylindrical shell The length is 300 mm. The lower end of the cylindrical shell and the spherical head are evenly distributed with small holes, the diameter of the holes is 22 mm, and the distance between the centers of the circular holes is 30 mm.

example 2

[0049] as per figure 1 The structure shown allows for the fabrication and installation of the in-reactor gas distributor according to the invention. The specific structural parameters are as follows, the diameter of the reactor is 4000 mm, the diameter of the gas inlet is 500 mm, the diameter of the cylindrical shell of the gas distributor is 800 mm, the diameter of the spherical head is the same, and the length of the cylindrical shell is 250 mm. The spherical head has evenly distributed small holes with a diameter of 18 mm and a center-to-center distance of 27 mm.

example 3

[0051] as per figure 1 The structure shown allows for the fabrication and installation of the in-reactor gas distributor according to the invention. The specific structural parameters are as follows. The diameter of the reactor is 5000 mm, the diameter of the gas inlet is 600 mm, the diameter of the cylindrical shell of the gas distributor is 900 mm, and the diameter of the spherical head is 1200 mm. The height of the transition section is 120 mm. The lower end of the cylindrical shell and the spherical head are evenly distributed with small holes, the diameter of the holes is 22 mm, and the distance between the centers of the circular holes is 30 mm.

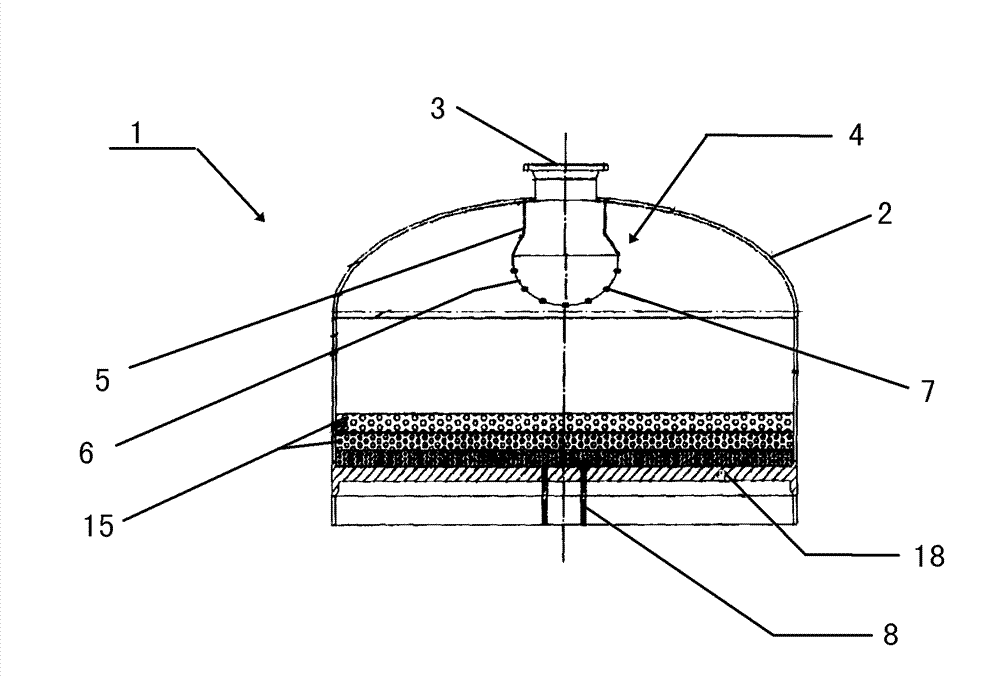

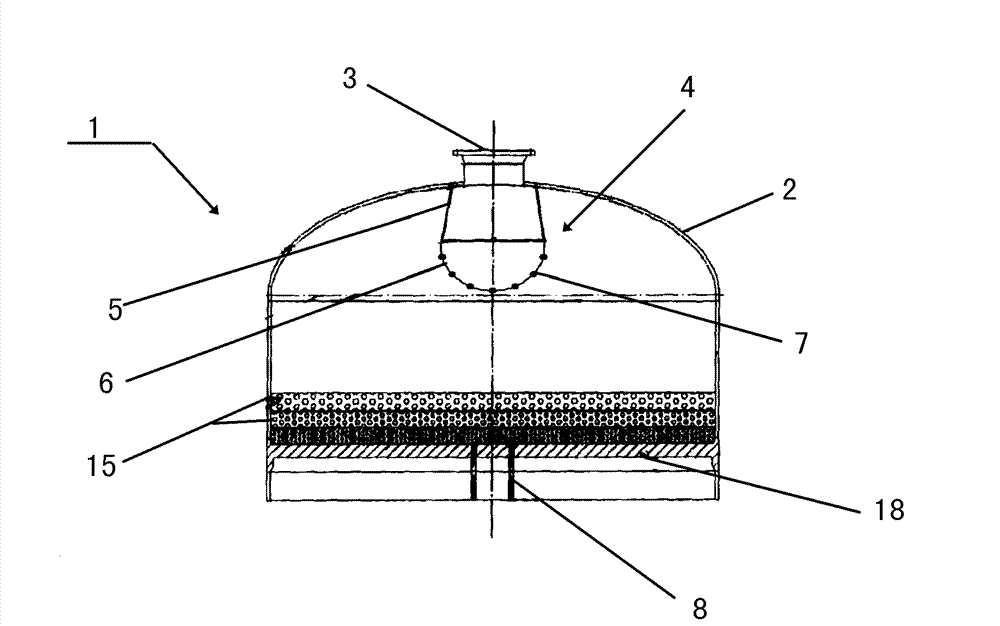

[0052] figure 2 for along Figure 5 The schematic longitudinal sectional view of the upper part of the vinyl acetate synthesis reactor according to the second embodiment of the present invention is taken by the section line B-B shown.

[0053] The upper part of the second embodiment of the vinyl acetate synthesis reactor o...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| pore size | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com