Catalyst for acetylene method vinyl acetate synthesis

A technology of vinyl acetate and catalyst, which is applied in the field of acetylene gas-phase vinyl acetate catalyst, can solve the problems of low acetylene single-pass conversion rate and low catalyst activity, and achieve the effects of improving acetylene single-pass conversion rate, catalyst activity and activity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

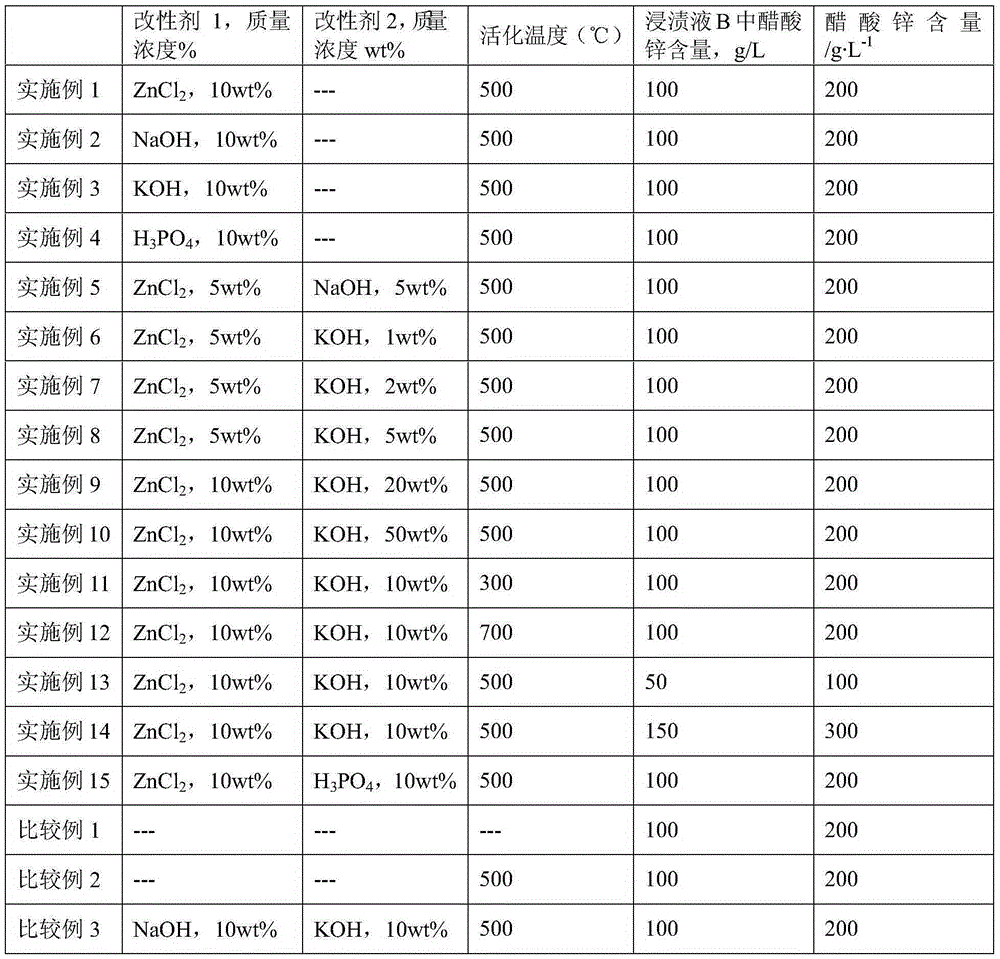

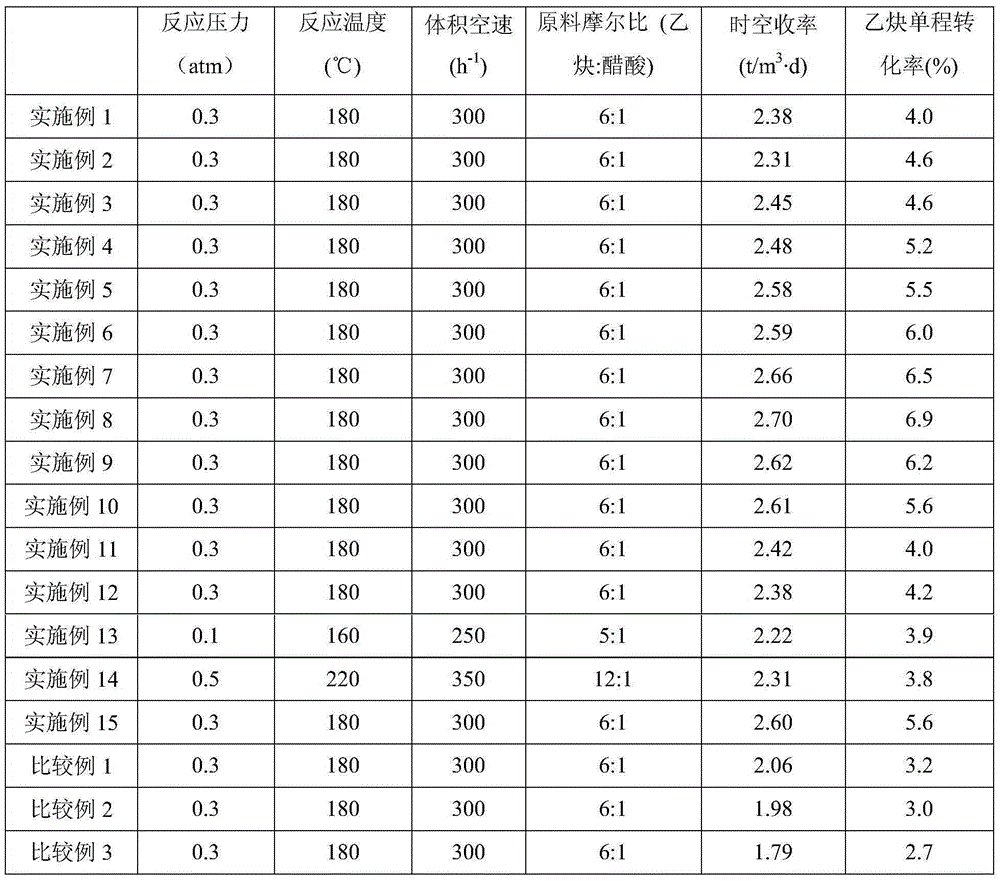

Examples

Embodiment 1

[0040] (1) carrier preparation

[0041] a) Impregnation: at normal temperature, 100ml of activated carbon A is placed in 120ml of ZnCl with a mass concentration of 10.0wt%. 2 In aqueous solution, after 24h, wash repeatedly with deionized water until the filtrate is neutral;

[0042] b) Drying: Drying at 60°C for 24 hours to obtain modified carbon B;

[0043] c) Activation: the modified carbon B is placed in the atmosphere furnace, under N 2 Under atmospheric conditions, program the temperature to 500°C, keep the temperature for 3 hours, and then cool to room temperature for later use; the programmed temperature rise rate is 10°C / min, N 2 The flow rate was 20 ml / min to obtain the carrier.

[0044] (2) Catalyst preparation

[0045] a) Preparation of impregnation solution: Weigh 20.0g of zinc acetate (molecular formula: Zn(CH 3 COO) 2 ) was dissolved in deionized water, and acetic acid was used to adjust its pH value to 4.85 to obtain 200ml impregnation solution C, wherein ...

Embodiment 2

[0059] (1) carrier preparation

[0060] a) Impregnation: under normal temperature conditions, place 100ml of activated carbon A in 120ml of NaOH aqueous solution with a mass concentration of 10.0wt%, and after 24h, wash repeatedly with deionized water until the filtrate is neutral;

[0061] b) Drying: Drying at 60°C for 24 hours to obtain modified carbon B;

[0062] c) Activation: the modified carbon B is placed in the atmosphere furnace, under N 2 Under atmospheric conditions, program the temperature to 500°C, keep the temperature for 3 hours, and then cool to room temperature for later use; the programmed temperature rise rate is 10°C / min, N 2 The flow rate was 20 ml / min to obtain the carrier.

[0063] (2) Catalyst preparation

[0064] a) Preparation of impregnation solution: Weigh 20.0g of zinc acetate (molecular formula: Zn(CH 3 COO) 2 ) was dissolved in deionized water, and acetic acid was used to adjust its pH value to 4.85 to obtain 200ml impregnation solution C, w...

Embodiment 3

[0078] (1) carrier preparation

[0079] a) Impregnation: under normal temperature conditions, place 100ml of activated carbon A in 120ml of KOH aqueous solution with a mass concentration of 10.0wt%, after 24h, wash repeatedly with deionized water until the filtrate is neutral;

[0080] b) Drying: Drying at 60°C for 24 hours to obtain modified carbon B;

[0081] c) Activation: the modified carbon B is placed in the atmosphere furnace, under N 2 Under atmospheric conditions, program the temperature to 500°C, keep the temperature for 3 hours, and then cool to room temperature for later use; the programmed temperature rise rate is 10°C / min, N 2 The flow rate was 20 ml / min to obtain the carrier.

[0082] (2) Catalyst preparation

[0083] a) Preparation of impregnation solution: Weigh 20.0g of zinc acetate (molecular formula: Zn(CH 3 COO) 2 ) was dissolved in deionized water, and acetic acid was used to adjust its pH value to 4.85 to obtain 200ml impregnation solution C, wherei...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com