Synthesis of porous ZSM-5 zeolite and gamma-Al2O3 composite material and preparation of hydrodesulfurization catalyst

A MZSM-5-A, composite material technology, applied in physical/chemical process catalysts, molecular sieve catalysts, refined hydrocarbon oil, etc., can solve the problems of low mechanical strength of porous zeolite, difficult to apply, difficult to shape, etc., to achieve repeatability High sex, improve interaction, avoid the effect of agglomeration

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

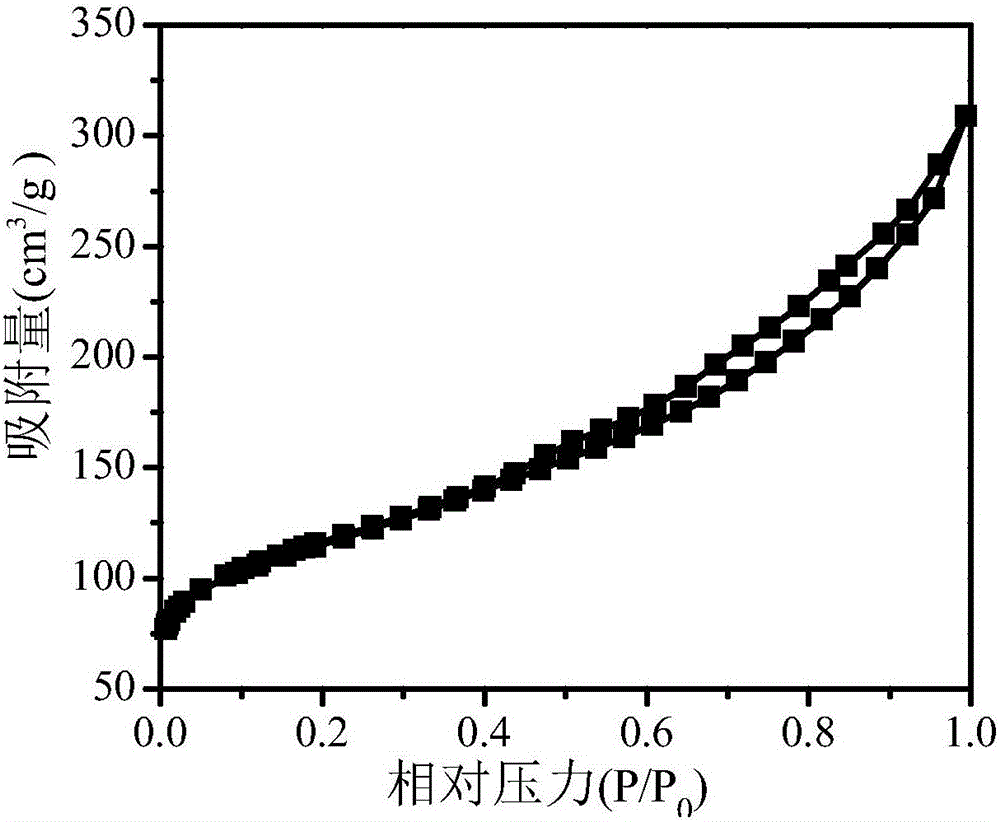

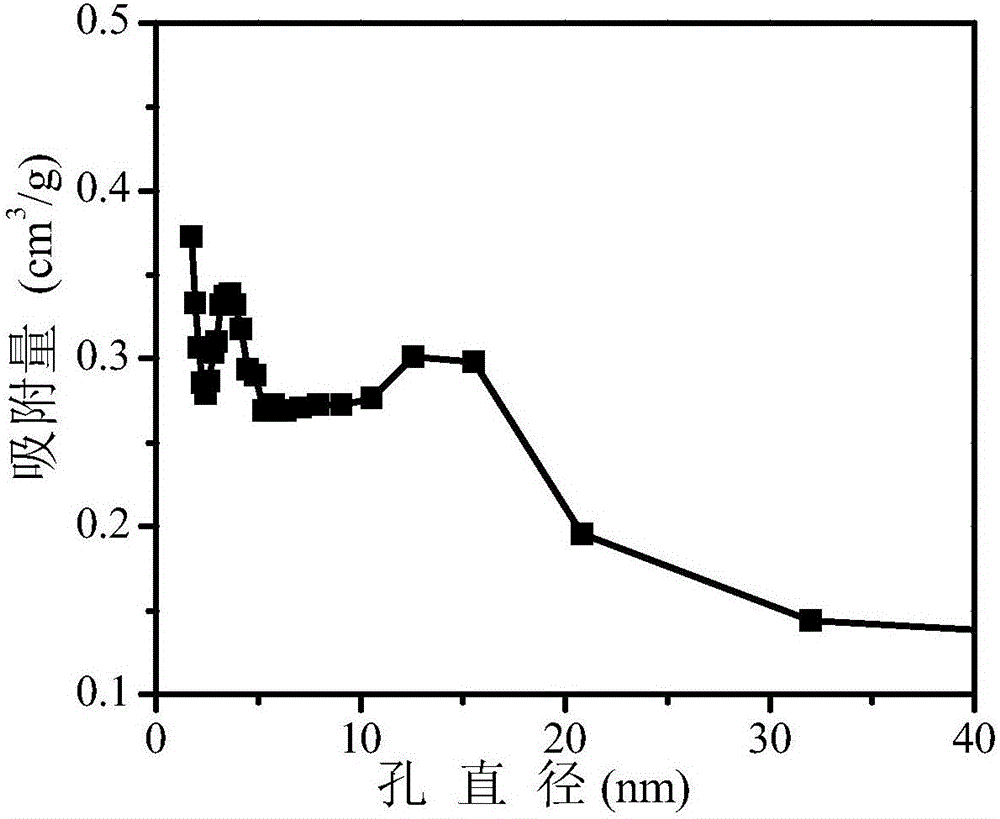

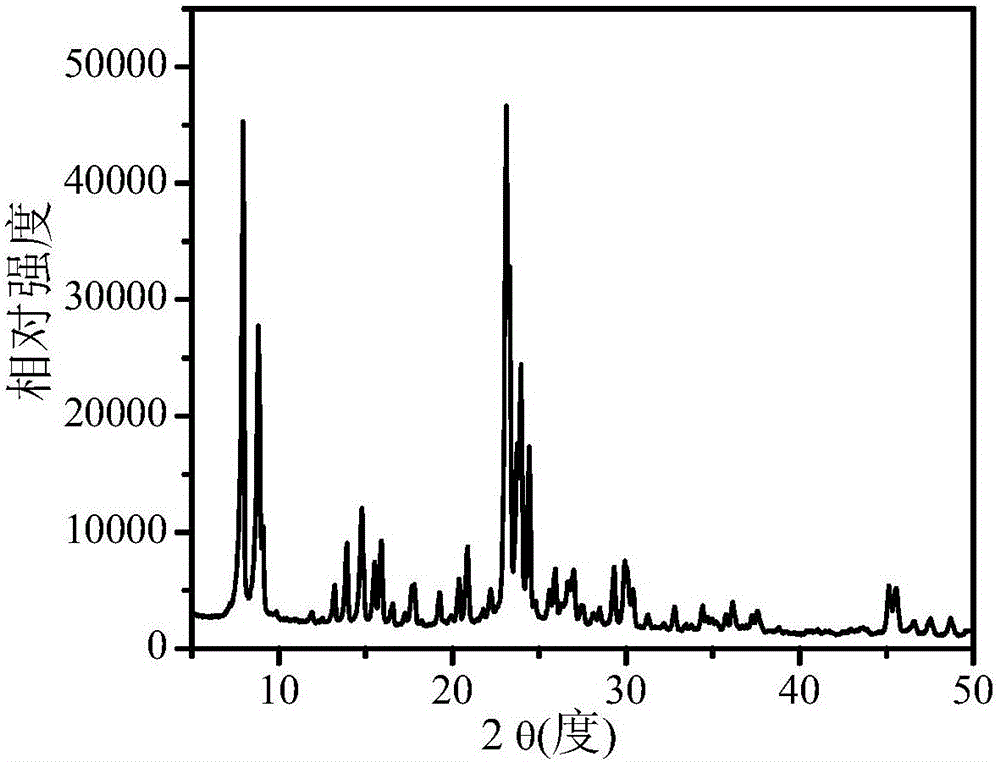

[0029] Preparation of ZSM-5: γ-Al 2 O 3 = 9:1 The composite material method is realized by the following steps:

[0030] (1) Weigh 0.357g NaAlO 2 And 0.522g NaOH dissolved in 19.6mL water, add a mixed solution of ethyl orthosilicate and TAPOH (10mL TEOS and 26mL 25wt.% TPAOH), when it is completely dissolved, the NaAlO 2 Take Al 2 O 3 Calculated, TEOS is SiO 2 Calculate, then add 2.5mL DEAB, the molar ratio of each material is Al 2 O 3 :Na 2 O:TPAOH:SiO 2 :DEAB:H 2 O=1:4:20:20:2:500. After the reaction is complete, 0.72 g of pseudo-boehmite is added and stirred until it is completely dissolved. The reacted mixture was added to a 50mL hydrothermal kettle, and then crystallized at 180°C for 3 days. After natural cooling, wash with water at room temperature, suction filtration, 100℃ oven, 550℃ calcination for 5h. The texture properties of the resulting carrier are shown in Table 1.

[0031] (2) Add 0.0699g (NH 4 ) 6 Mo 7 O 24 ·4H 2 O, 0.0576g Co(NO 3 ) 2 ·6H 2 O and 0.0579g EDTA dis...

Embodiment 2

[0033] Preparation of ZSM-5: γ-Al 2 O 3 = 9:1 The composite material method is realized by the following steps:

[0034] (1) Weigh 0.357g NaAlO 2 And 0.522g NaOH dissolved in 19.6mL water, add a mixed solution of TEOS and TAPOH (10mL TEOS and 26mL 25wt.% TPAOH), when it is completely dissolved, the NaAlO 2 Take Al 2 O 3 Calculated, TEOS is SiO 2 Calculate, then add 2.5mL DEAB, the molar ratio of each material is Al 2 O 3 :Na 2 O:TPAOH:SiO 2 :DEAB:H 2 O=1:4:20:20:2:500. After the reaction is complete, 0.72 g of pseudo-boehmite is added and stirred until it is completely dissolved. The reacted mixture was added to a 50mL hydrothermal kettle, and then crystallized at 180°C for 3 days. Filter, wash, dry, and calcine at 550°C for 5 hours. The texture properties of the resulting carrier are shown in Table 1.

[0035] (2) 0.2116g (NH 4 ) 6 Mo 7 O 24 ·4H 2 O, 0.1744g Co(NO 3 ) 2 ·6H 2 O and 0.1751g EDTA are dissolved in a certain amount of water, and after all are dissolved, they are dro...

Embodiment 3

[0037] Preparation of ZSM-5: γ-Al 2 O 3 = 9:1 The composite material method is realized by the following steps:

[0038] (1) Weigh 0.357g NaAlO 2 And 0.522g NaOH dissolved in 19.6mL water, add a mixed solution of TEOS and TAPOH (10mL TEOS and 26mL 25wt.% TPAOH), when it is completely dissolved, the NaAlO 2 Take Al 2 O 3 Calculated, TEOS is SiO 2 Calculate, then add 2.5mL DEAB, the molar ratio of each material is Al 2 O 3 :Na 2 O:TPAOH:SiO 2 :DEAB:H 2 O=1:4:40:20:2:500. After the reaction is complete, 0.72 g of pseudo-boehmite is added and stirred until it is completely dissolved. The reacted mixture was added to a 50mL hydrothermal kettle, and then crystallized at 180°C for 3 days. Filter, wash, dry, and calcine at 550°C for 5 hours. The texture properties of the resulting carrier are shown in Table 1.

[0039] (2) 0.1964g (NH 4 ) 6 Mo 7 O 24 ·4H 2 O, 0.1618g Co(NO 3 ) 2 ·6H 2 O and 0.1628g EDTA are dissolved in a certain amount of water, and after all are dissolved, drip into 1g...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com