Quantitative feeding cement raw material roller press system

A cement raw material and roller press technology, which is applied in the field of roller press systems, can solve problems such as system tripping, increased vibration of roller presses, and excessive particle size of small crushed stones discharged from the crusher, achieving good results and improving work efficiency. Efficiency, the effect of realizing recycling

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

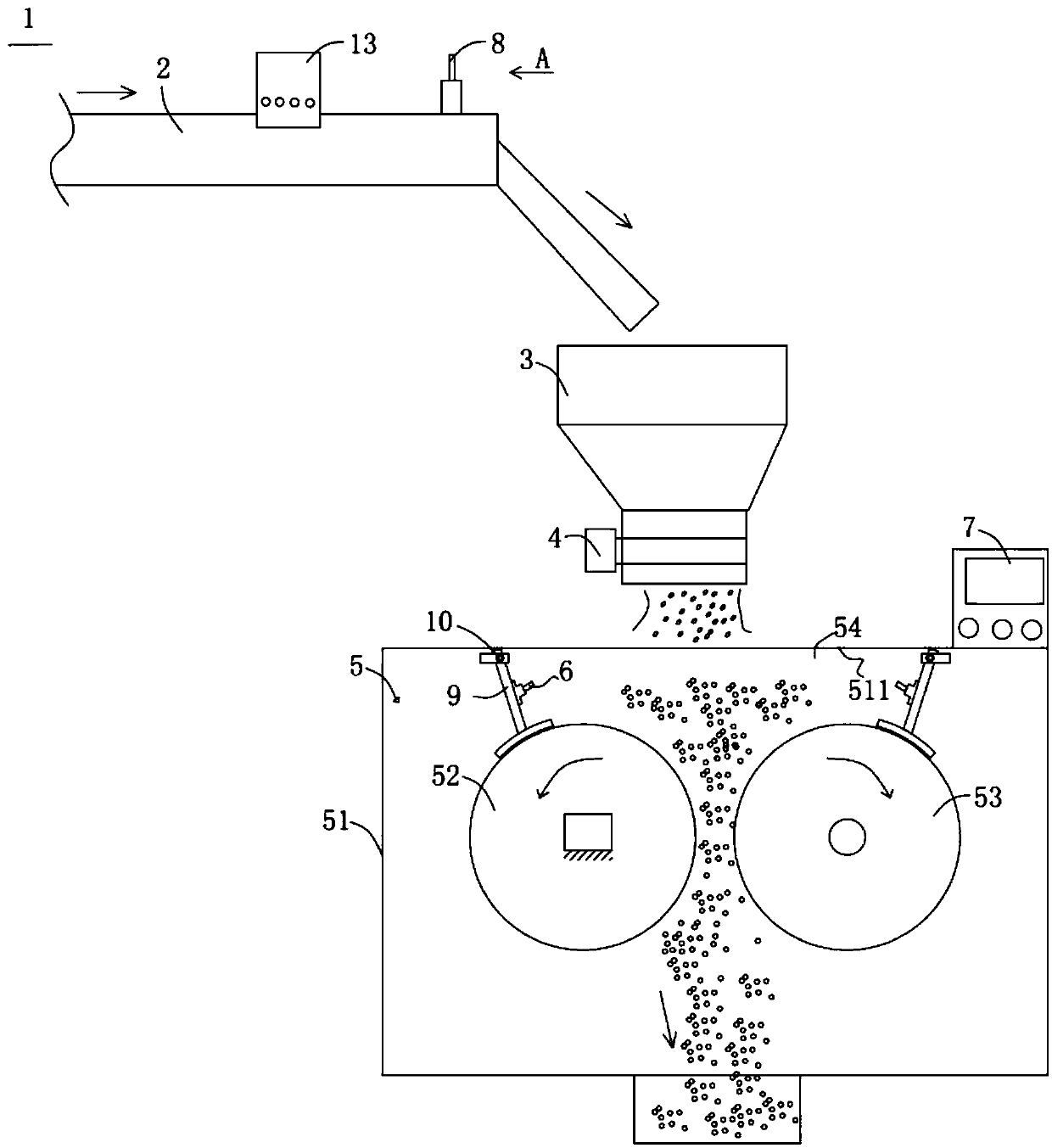

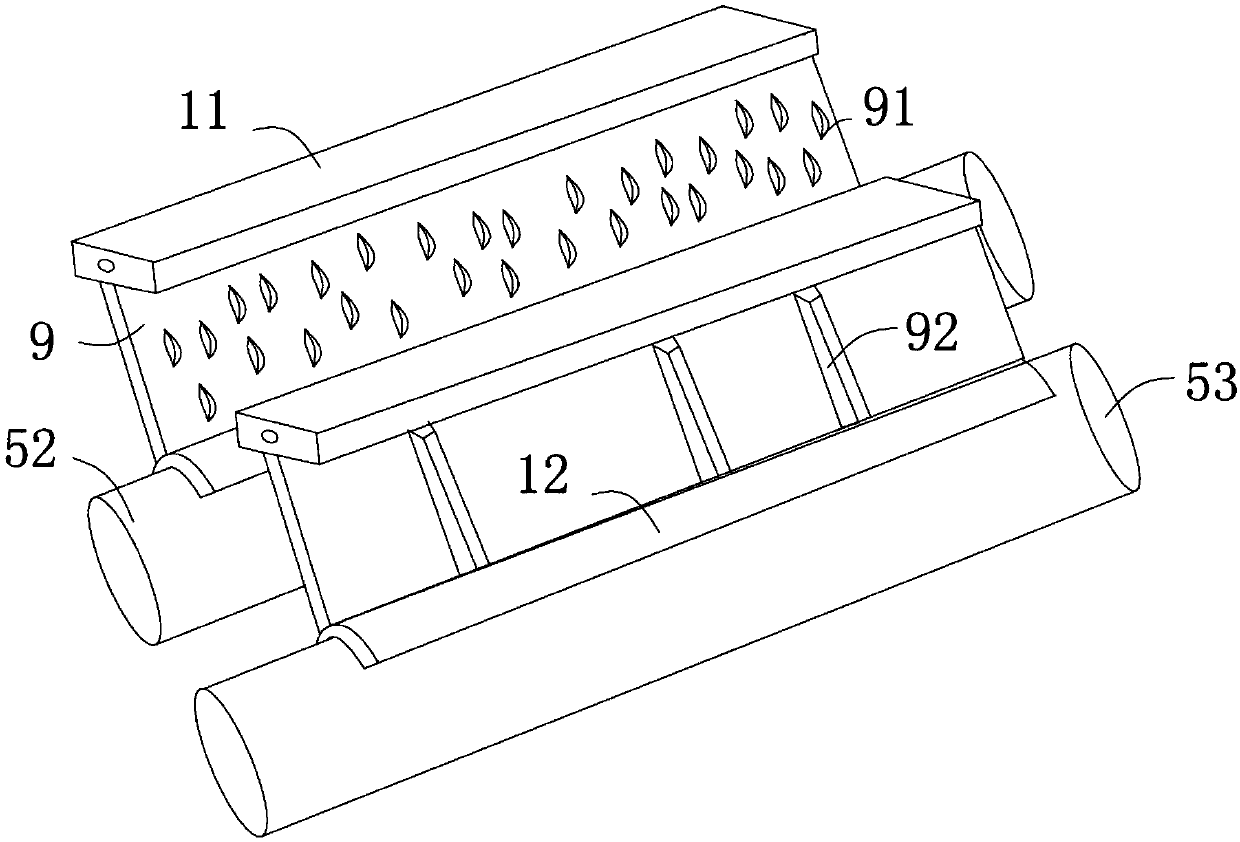

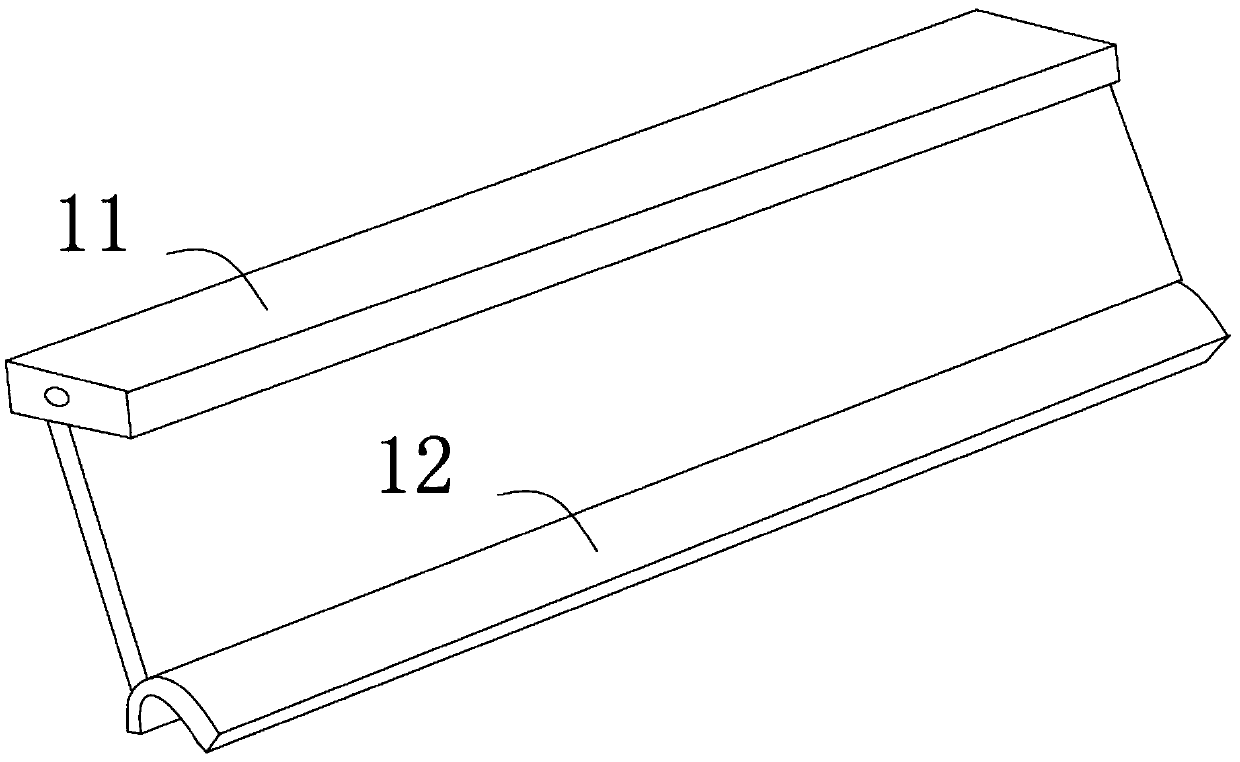

[0034] The present invention discloses a cement raw meal roller press system 1 for quantitative blanking according to an embodiment, please refer to Figure 1-8 As shown, the cement raw meal roller press 5 system 1 used for rolling cement raw meal and quantitative blanking includes a feed conveying device 2, a feeding device 3, a material locking solenoid valve 4, a roller press 5, a sensor 6 and Control device 7, wherein:

[0035] Please refer to figure 1 As shown, the feed conveying device 2 is used for conveying cement raw materials, and the feed conveying device 2 can be a conveyor belt or a conveying dragon, but it is not limited thereto, and those skilled in the art can choose other suitable ones according to actual production requirements. Conveyor 3.

[0036] In a preferred embodiment, please refer to figure 1 As shown, the cement raw meal roller press system 1 for quantitative blanking also includes an automatic material partition 8, which is arranged at the discha...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com