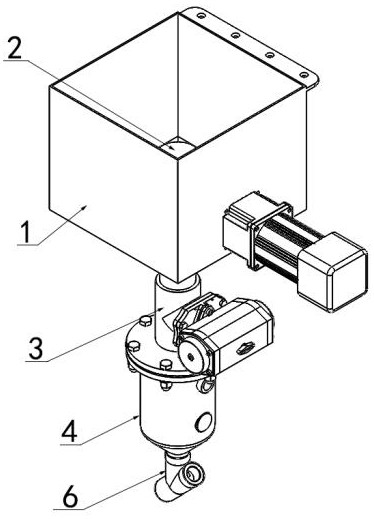

Vertical intermittent powder and particle material dilute phase jet conveying device

A conveying device, intermittent technology, applied in the direction of spraying device, liquid spraying device, conveyor, etc., can solve the problems that materials cannot fall continuously, cannot be adjusted, pipeline blockage, etc., so as to improve the efficiency of spray release and reduce manual work , the effect of preventing clogging

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment approach

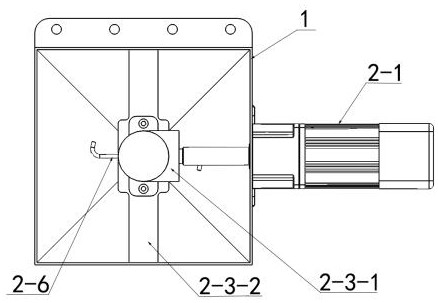

[0053] Based on the above embodiment, the fixing part 2-3 includes a protective shell 2-3-1 and a support plate 2-3-2, and the bevel teeth a2-4 and bevel teeth b2-5 are wrapped in the protective shell 2-3-1 , the protective shell 2-3-1 includes a bearing for socketing the output shaft of the motor 2-1 and a bearing for socketing the screw rod 2-2, and the support plate 2-3-2 is a horizontal bar The two ends of the support plate 2-3-2 are fixedly connected on the inner wall of the storage hopper 1, the middle part of the support plate 2-3-2 has a hole for passing through the screw rod 2-2, and the protective shell 2-3-1 is fixedly installed on the support Above the plate 2-3-2, the screw rod is vertically fixed inside the storage hopper, and the material is prevented from entering between the bevel teeth a and bevel teeth b.

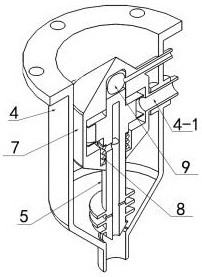

[0054] Based on the above embodiment, the lower end discharge port of the spray tank 4 is connected to the material input port 6-1 of the spray tee 6, an...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com