Optical polyester film and optical laminated polyester film

An optical polyester film, polyurethane resin technology, applied in polyester coatings, polyurea/polyurethane coatings, applications, etc., can solve problems such as poor adhesion, and achieve reprocessing, high transparency, and excellent anti-blocking properties. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

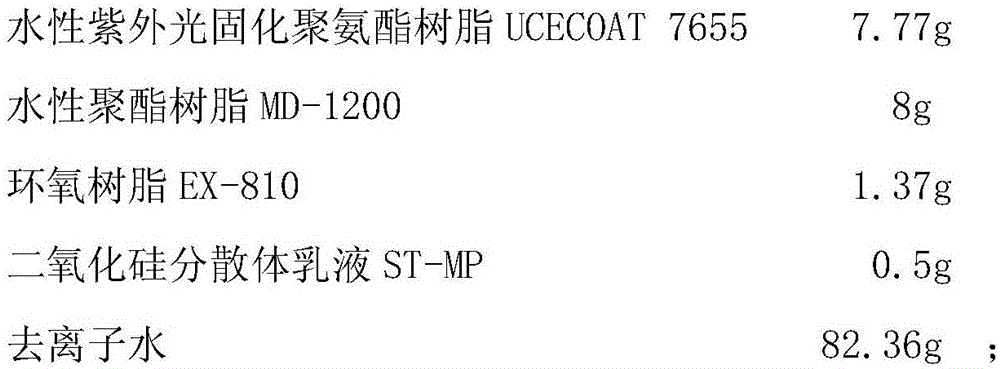

[0048] Preparation of primer coating solution (Ⅰ)

[0049]

[0050] Get 7.77g water-based UV-curable polyurethane resin UCECOAT7655 (solid content is 35%, allnex resin Co., Ltd.), 8g water-based polyester resin MD-1200 (solid content is 34%, Toyobo Co., Ltd.), 1.37g water-based epoxy Resin EX-810 (solid content is 99%, Nagase Sangyo Co., Ltd.), dispersion emulsion ST-MP of 0.5 g of silicon dioxide (solid content is 40%, Nissan Chemical Co., Ltd.), 10 g of isopropyl alcohol, 82.36 g Deionized water was uniformly dispersed by a high-shear emulsifier to obtain a primer coating solution with a solid content of 7%.

[0051] The preparation of optical polyester film is the polyethylene terephthalate polyester chip (middle layer b layer) that intrinsic viscosity is 0.65dL / g respectively; Alcohol ester polyester chips and masterbatch chips (outer layer a) containing 400 ppm of silica particles with an average particle size of 2.5 μm are melted at 280 ° C, stacked in the three-laye...

Embodiment 2

[0055] In Example 1, the undercoat coating liquid (I) was changed to other than the undercoat coating liquid (II), and an optical polyester film and a laminated polyester film for optics were obtained in the same manner as in Example 1, Measure its performance (see Table 1).

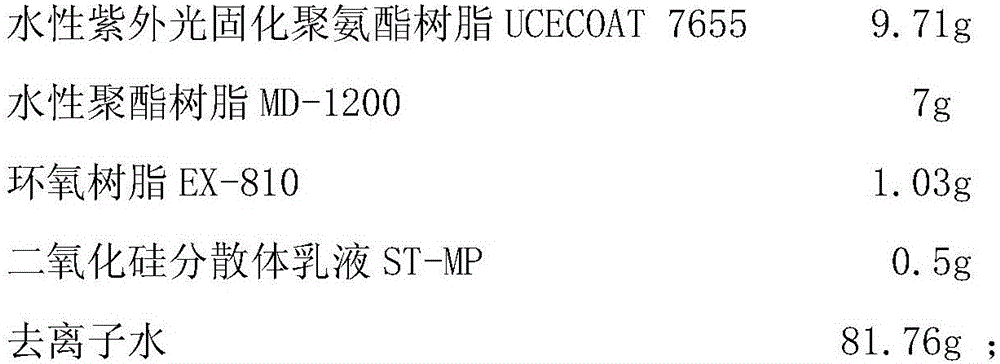

[0056] Preparation of primer coating solution (Ⅱ)

[0057]

Embodiment 3

[0059] The undercoat coating solution (I) in embodiment 1 is changed to undercoat coating solution (Ⅲ), and the single-sided coating undercoat is changed to the double-sided coating bottom layer, to be the same as in embodiment 1 The method obtains optical polyester film and optical laminated polyester film, and measures its performance (see Table 1).

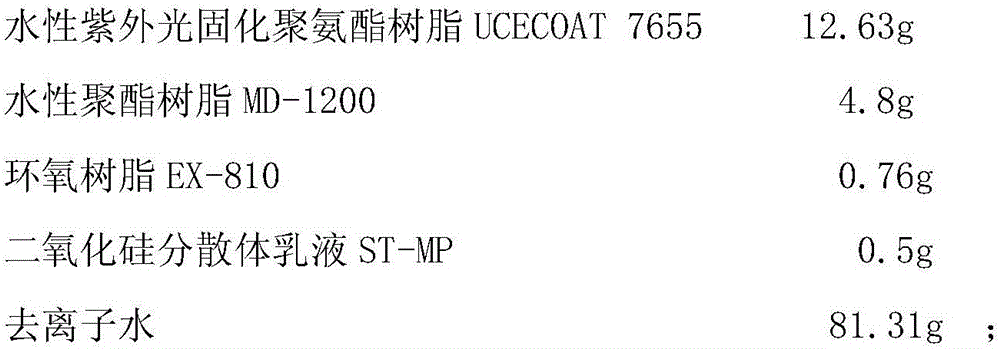

[0060] Preparation of primer coating solution (Ⅲ)

[0061]

PUM

| Property | Measurement | Unit |

|---|---|---|

| glass transition temperature | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com