Composition containing vinyl alcohol polymer

一种组合物、乙烯醇的技术,应用在含颜料涂层、印刷、纺织品和造纸等方向,能够解决无法溶解、未消除等问题,达到高耐水性或抗粘连性、耐水性或抗粘连性优异、操作性优异的效果

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

[0191] Hereinafter, the present invention will be described in more detail by way of examples, but the present invention is not limited to these examples. In addition, in the following examples and comparative examples, unless otherwise specified, parts and % represent parts by mass and % by mass, respectively.

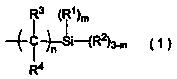

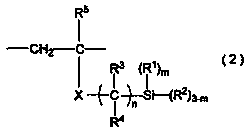

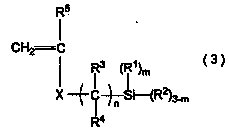

[0192] It should be noted that the monomer (monomer A) having a silyl group used in Examples and Comparative Examples is as follows:

[0193] MAmPTMS : 3-Methacrylamidopropyltrimethoxysilane

[0194] MAmOTMS : 8-Methacrylamidopropyltrimethoxysilane

[0195] MAmDDTMS: 12-Methacrylamidododecyltrimethoxysilane

[0196] MAmODTMS: 18-methacrylamidooctadecyltrimethoxysilane

[0197] 4-PTMS : 4-pentenyltrimethoxysilane

[0198] VMS : Vinyltrimethoxysilane

[0199] MAmMTMS : Methacrylamidomethyltrimethoxysilane

[0200] AMPTMS : 2-acrylamido-2-methylpropyltrimethoxysilane.

[0201] In addition, the compound (B) and polyamide polyamine epichlorohydrin resin (C) used in ...

Synthetic example 1

[0212] [Synthesis Example 1] Preparation of PVA1

[0213] In a 6L detachable flask equipped with a stirrer, a reflux cooling pipe, a nitrogen introduction pipe, a comonomer dropping port, and an initiator adding port, 1,500 g of vinyl acetate, 500 g of methanol, and 1.87 g of methanol having the above formula In the MAmPTMS of the monomer (monomer A) of the group represented by (1), nitrogen substitution was performed in the system for 30 minutes while nitrogen bubbling was performed. In addition, as a delay solution (delay solution), MAmPTMS was dissolved in methanol to prepare a comonomer solution with a concentration of 8%, and nitrogen replacement was performed by bubbling with nitrogen gas. The temperature rise of the reactor was started, and when the internal temperature reached 60°C, 0.8 g of 2,2'-azobisisobutyronitrile (AIBN) was added to start polymerization. The delayed solution was added dropwise, and the polymerization was carried out at 60° C. for 2.7 hours while...

Embodiment 1

[0231] (composition and film preparation)

[0232] A 4% aqueous solution of PVA1 prepared was added to a 10% aqueous solution of titanium lactate (Ti compound: TC-310 manufactured by Matsumoto Pharmaceutical Co., Ltd.), so that the titanium lactate solid content relative to 100 mass parts of PVA solid content was 10 mass parts, and obtained Composition of Example 1. This composition was cast at 20° C. to obtain a film with a thickness of 40 μm.

[0233] (Composition and Preparation of Thermosensitive Recording Material)

[0234] 90 g of aluminum hydroxide powder (manufactured by Showa Denko Co., Ltd., Higilite H42) was poured into 210 g of distilled water, and stirred by hand. Then, it was stirred at a rotation speed of 13,500 rpm for 5 minutes using a homomixer (manufactured by IKA-Labortechnik, T-25-SI type) to prepare a dispersion liquid of aluminum hydroxide (aluminum hydroxide concentration: 30%). In addition, the PVA1 obtained above was dissolved in water to prepare a...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| degree of polymerization | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com