Composite type TBM synchronous grouting material and grouting method

A technology of synchronous grouting and grouting materials, which is applied in the direction of chemical instruments and methods, earthwork drilling, drilling compositions, etc., can solve the problems of segment out-of-roundness, which is not conducive to the stability of the three-dimensional position of the segment, and reduce the Fluidity, avoiding the expansion of surrounding rock cracks, and ensuring the effect of engineering quality

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0031] A composite TBM synchronous grouting method,

[0032] 1) Clean the pipeline of the grouting system;

[0033] 2), evenly add the grouting materials except the quick-setting agent, and continuously stir and mix the grouting materials to obtain the primary slurry;

[0034] 3) During the excavation process, when there is an annular gap between the segment and the formation, and between the segment and the shield tail shell, a liquid accelerator delivery pump is installed near the grouting system to mix the accelerator with the primary The slurry is injected into the annular gap;

[0035] 4) During the grouting process, the grout is injected into the annular gap in 4-6 strands;

[0036] 5) When dark grout is found at the TBM cutterhead, stop grouting.

[0037] In conjunction with the specific implementation scheme, this technical solution is further described:

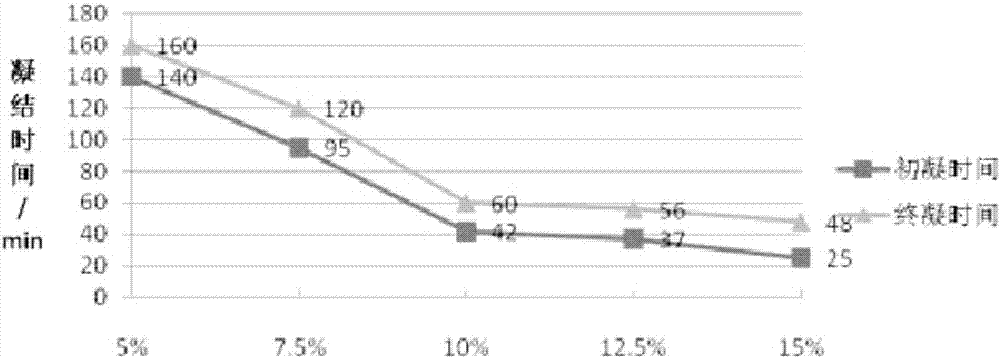

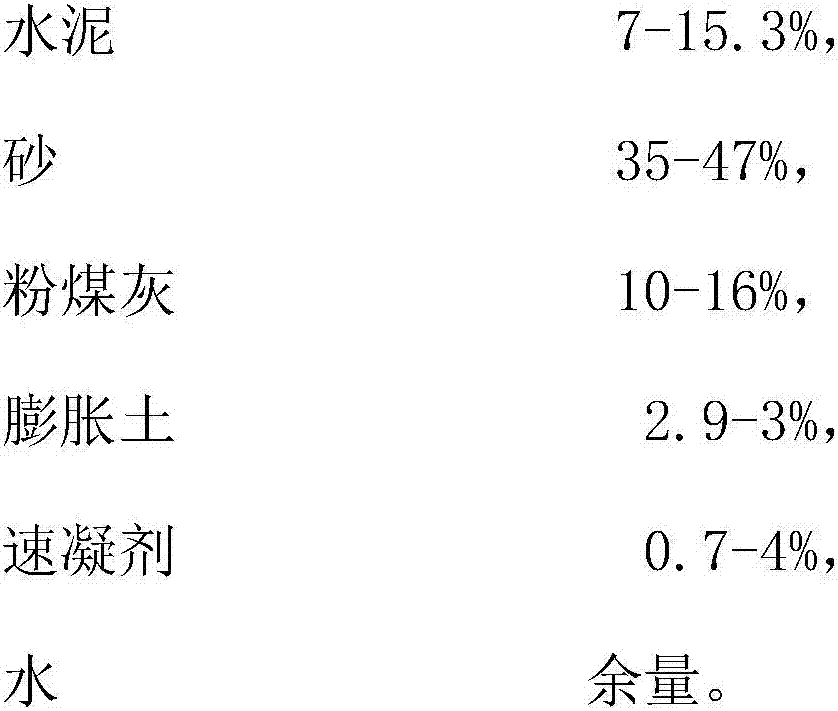

[0038] A composite TBM synchronous grouting material, the grouting material is composed of the following weigh...

PUM

| Property | Measurement | Unit |

|---|---|---|

| length | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com