Preparation method of waterborne micro porous waterproof and moisture permeable film

A waterproof and moisture-permeable film, microporous technology, applied in the textile field, can solve the problems of upper respiratory tract irritation and even injury, and does not meet the requirements of the consumer market, to achieve improved slipperiness and anti-adhesion, excellent elasticity and heat-sealing adhesion The effect of fit and uniform porosity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

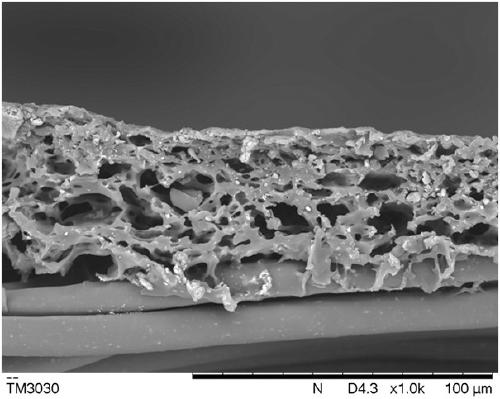

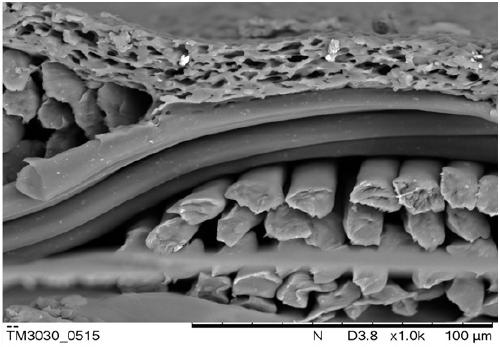

[0043] The water-based microporous waterproof and moisture-permeable membrane prepared in this embodiment has a large pore size, high moisture permeability, and low water pressure resistance, and is suitable for clothing fabrics such as shoes and windbreakers.

[0044] The specific preparation process is described in detail as follows.

[0045] S1. Raw material preparation, batching according to the raw material composition and ratio of Example 1 in Table 1.

[0046]S2. Mixing, mixing the raw materials, stirring at a rotating speed of 1000 RPM, fully mixing and emulsifying, stirring, and performing vacuum defoaming treatment to obtain a defoamed colloidal mixture.

[0047] S3. Coating, evenly coat the mixture on the release paper, and control the coating amount to 150g / m 2 ~180g / m 2 , The coating speed is 18m / min to 20m / min. The non-solidified state of the mixed material after coating enters step S4.

[0048] S4. Drying, send the release paper coated with the mixture into ...

Embodiment 2

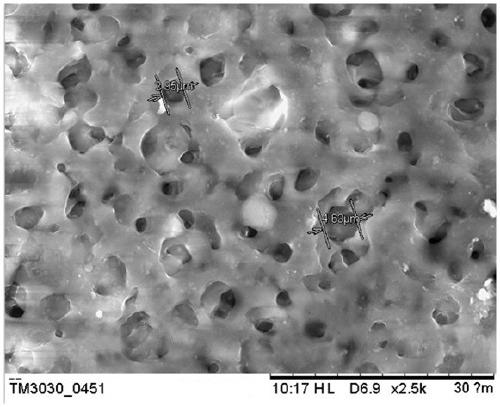

[0052] The water-based microporous waterproof and moisture-permeable membrane prepared in this embodiment has small pore diameter, low moisture permeability and high water pressure resistance, and is suitable for clothing fabrics such as jackets and ski suits.

[0053] The specific preparation process is described in detail as follows.

[0054] S1. Prepare materials, carry out batching according to the raw material composition and ratio of Example 2 in Table 1.

[0055] S2. Mixing, mixing the raw materials, stirring at a rotating speed of 1000 RPM, fully mixing and emulsifying, stirring, and performing vacuum defoaming treatment to obtain a defoamed colloidal mixture.

[0056] S3. Coating, evenly coat the mixture on the release paper, and control the coating amount to 300g / m 2 ~320g / m 2 , the coating speed is 10m / min to 12m / min. The non-solidified state of the mixed material after coating enters step S4.

[0057] S4. Drying. Send the release paper coated with the mixture i...

PUM

| Property | Measurement | Unit |

|---|---|---|

| pore size | aaaaa | aaaaa |

| elongation | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com