Automatic feeding device of knurling machine

An automatic feeding and engraving machine technology, applied in the direction of conveyor objects, transportation and packaging, etc., can solve the problems of low work efficiency and occupation of man-hours, and achieve the effects of saving man-hours, improving work efficiency and increasing the degree of automation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

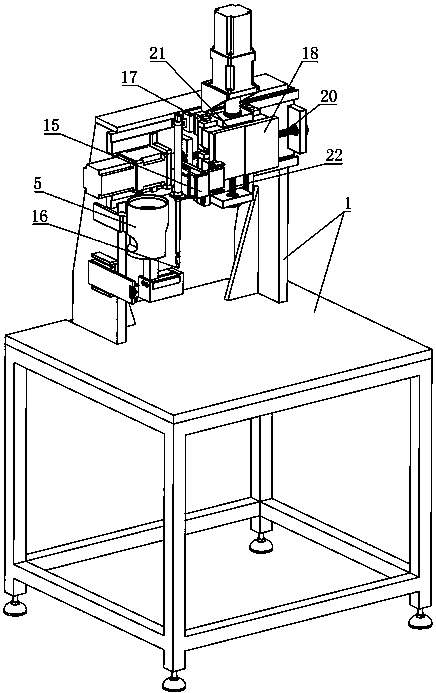

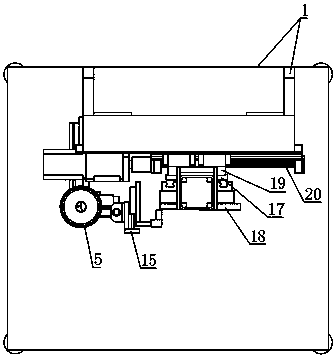

[0020] With reference to accompanying drawing, this engraving machine automatic feeding device comprises frame 1, is provided with quantitative unloading device, material conveying device on frame 1, the material output end of quantitative unloading device leads to the feeding end of material conveying device, The frame is provided with a workpiece pick-and-place device for transferring the workpiece from the discharge end of the material conveying device to the working position.

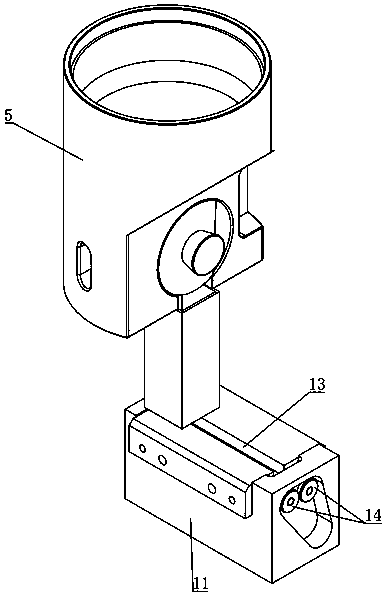

[0021] The quantitative unloading device includes a blanking body 5, which is provided with a trough 6, a blanking roller installation cavity 7 from top to bottom, and the trough 6 is connected to the blanking roller installation cavity 7. There is a blanking hole 8, and the blanking machine body 5 is provided with a discharge port 9 connected to the blanking roller installation cavity 7, and a blanking roller that can rotate under the drive of the power device is installed in the blanking roller ins...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com