Unpowered natural powder discharging device

An unloading device and power technology, which is applied in the field of unpowered unloading devices, can solve the problems of restricting the stable realization of process requirements, affecting the improvement of process quality and efficiency, labor and time and materials, and solving self-arch blocking. , Fast installation and maintenance, and the effect of reducing the probability of arching

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

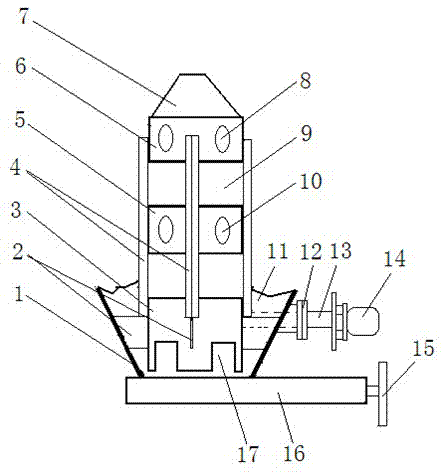

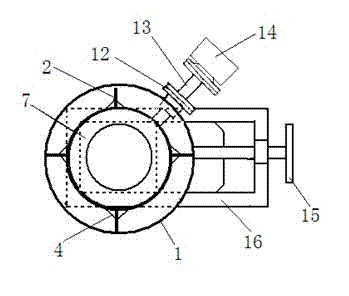

[0018] The present invention will be further described below in conjunction with the accompanying drawings.

[0019] like figure 1 , figure 2 , the powder unpowered integral flow natural unloading device provided by the present invention includes a discharge cone 1 with a gate 16 located at the bottom of the silo 11, and the gate 16 is a commercially available manual gate with a handwheel 15, wherein, In the middle of the unloading cone 1, the bottom ring 3 is connected to the four horizontal support flanges 2 arranged at intervals, and then the four vertical struts 4 arranged at intervals on the outer wall of the bottom ring 3 are connected at intervals from bottom to top. There are a middle ring 5 and a top ring 6, and a top cover 7 is connected to the top ring 6, and a feeding opening 9 is formed between the bottom ring 3 and the middle ring 5, and between the middle ring 5 and the top ring 6 , so that the middle part of the discharge cone 1 at the bottom of the sil...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com