Blanking device for rare-earth electrolysis bath, and rare-earth electrolysis bath

An electrolytic cell and rare earth technology, applied in the direction of electrolytic components, electrolytic process, cells, etc., can solve the problems of reduced service life of the feeding device, poor fluidity of rare earth oxides, and wear of the feeding device, so as to facilitate maintenance and cleaning, save Headroom, easy-to-control effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

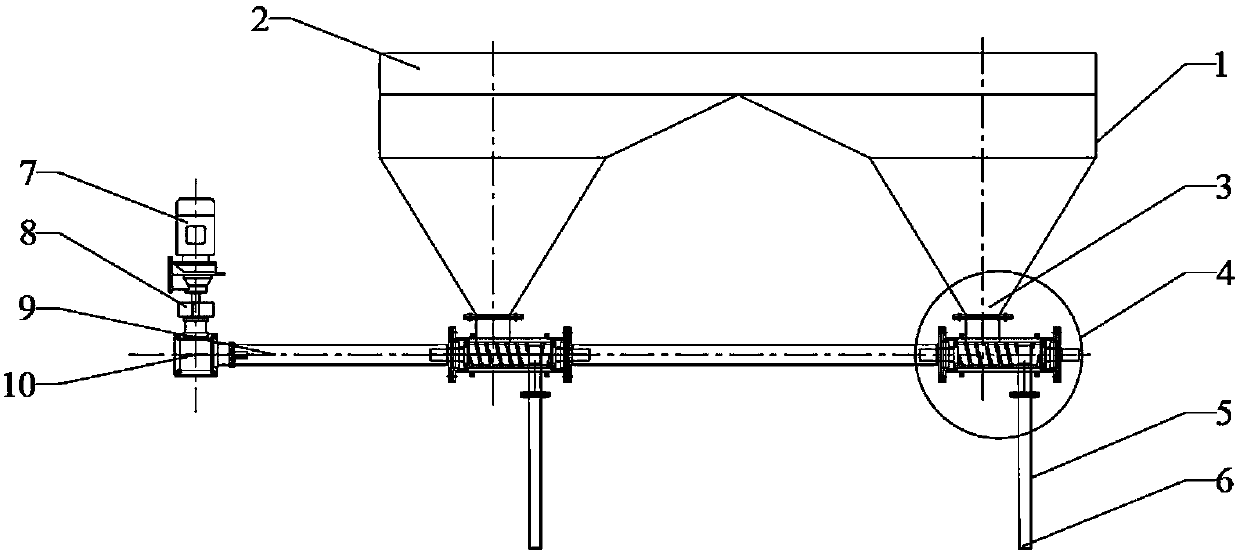

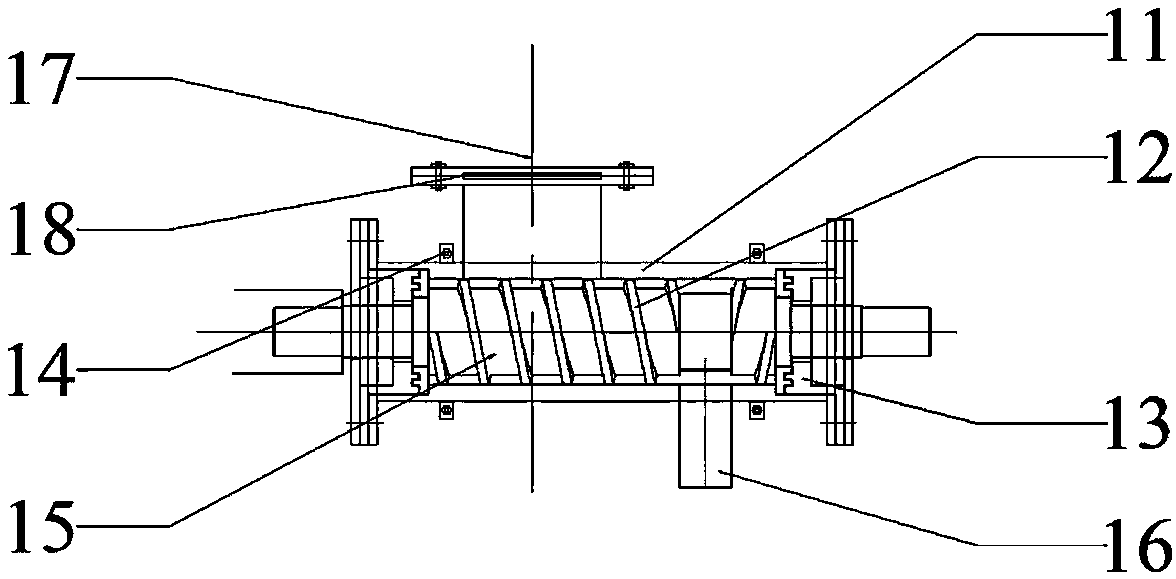

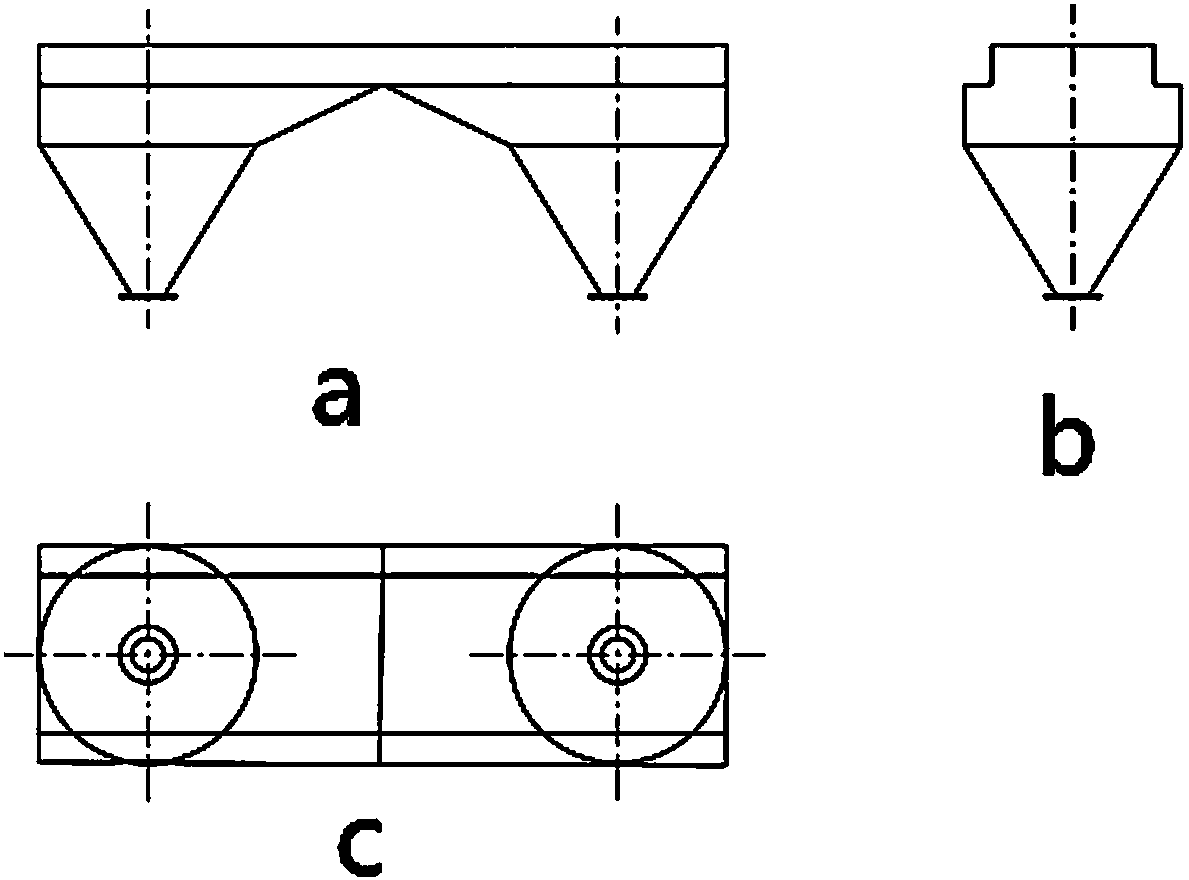

[0037] Such as figure 1 , figure 2 , image 3 As shown, a rare earth electrolyzer feeding device includes a screw feeder 4, a drive mechanism, a feeding pipe 5, and a feed bin 1; the top left end of the screw feeder 4 has a feed port 17, and the bottom right end is provided with There is a discharge port 16, and the inner cylindrical cavity is provided with a feeding thread column 15 and a coupling 13. The housing 11 outside the material screw column 15; the setting of the shaft coupling 13 can facilitate the transmission connection between the adjacent material delivery screw columns 15; , transmission shaft 9, the axis of the electrode 7 is at an angle of 90° to the axis of the transmission shaft 9; It is discharged into the electrolytic cell body; the upper part of the feed bin 1 is provided with a feeding port 2, the bottom of the feed bin is provided with a feeding port 3, the lower part of the feed bin 1 is connected with the screw feeder 4, and the feed bin 1 is con...

PUM

| Property | Measurement | Unit |

|---|---|---|

| distance | aaaaa | aaaaa |

| width | aaaaa | aaaaa |

| length | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com