Concentrated feed making equipment

A concentrated feed and equipment technology, which is applied in the field of concentrated feed production equipment, can solve the problems of inconvenient adjustment of single feed capacity, lack of downward guide drop, and inconvenient scraping of feed downwards.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

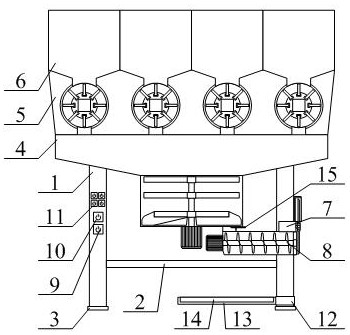

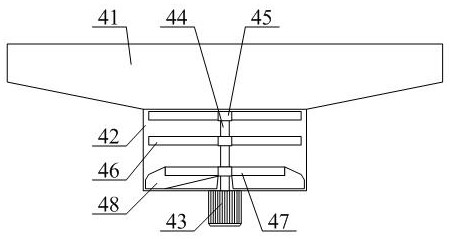

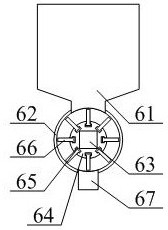

[0041] as attached figure 1 And attached image 3 shown

[0042]The invention provides concentrated feed production equipment, including a vertical mounting frame 1, a horizontal connecting frame 2, an anti-skid leg 3, a stirring and introducing frame structure 4, a connecting cover 5, a classification and quantitative introducing frame structure 6, a cutting frame structure 7, and a rotating extrusion frame structure 8. Stirring switch 9, extrusion switch 10, feed switch 11, ball bearing 12, transverse plate 13, anti-drop bucket 14 and transverse inserting plate 15, the bolts of the transverse connecting frame 2 are installed on the inner side of the longitudinal mounting frame 1 Bottom; the anti-skid legs 3 are glued to the lower part of the longitudinal mounting frame 1; the stirring and introducing frame structure 4 is installed on the upper part of the longitudinal mounting frame 1; the classification and quantitative introducing frame structure 6 is respectively install...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com