Breeding feeding machine with quantifying function

A feeding machine and functional technology, applied in the field of breeding feeders, can solve the problems of easy spoilage, general feeding effect, affecting the production of livestock products, etc., and achieve the effect of convenient adjustment and no manual intervention.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

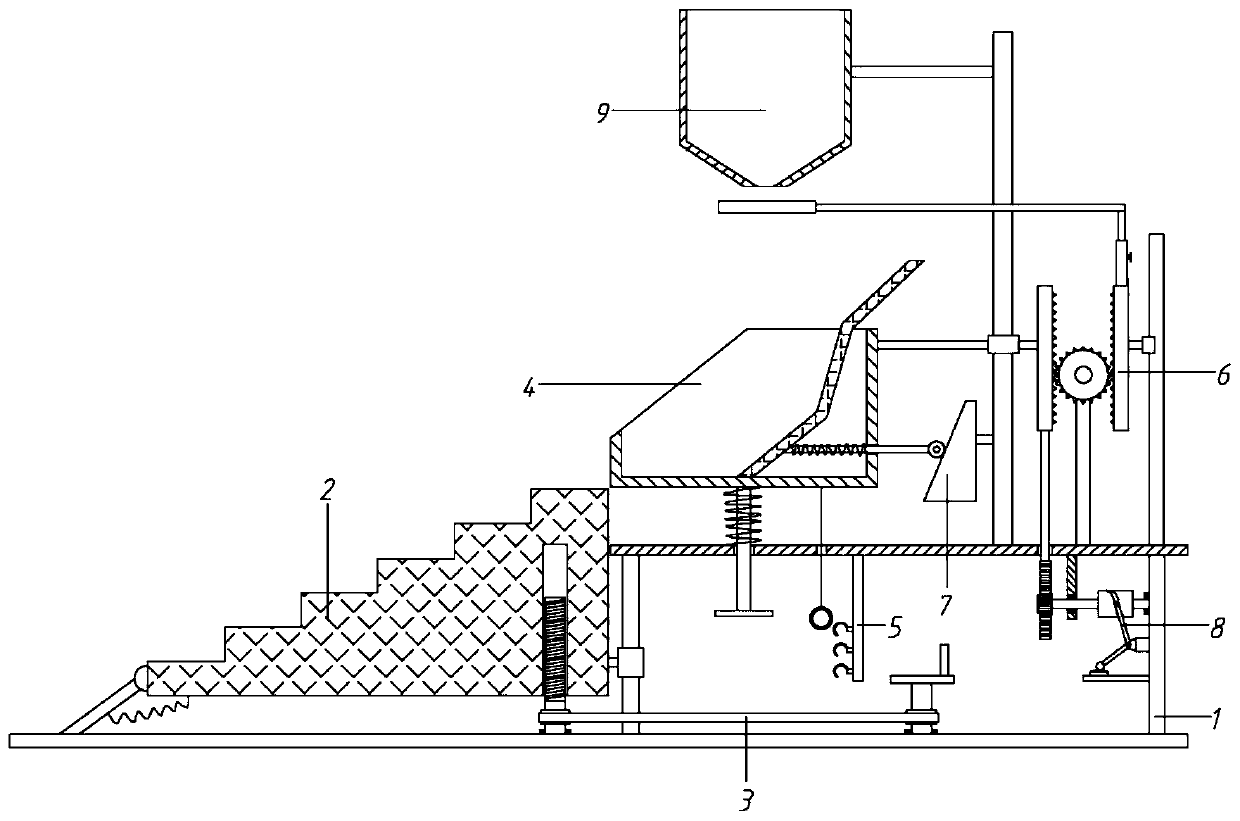

[0061] A breeding feeding machine with a quantitative function, comprising a frame 1, a lifting platform 2, an adjustment assembly 3, a material holding assembly 4, a locking assembly 5 and a blocking assembly 6;

[0062] The frame 1 includes a base 101, a left pole 102, a right pole 103, a support 104, a slide bar 105, a No. 1 connecting rod 106, and a storage hopper 107. The left pole 102 and the right pole 103 are arranged at intervals on the base 101; The top of the left pole 102 and the right pole 103 are connected by a support 104; the middle part of the support 104 is provided with a vertical slide bar 105, and the top of the slide bar 105 is connected with a storage hopper 107 to the left through the No. 1 connecting rod 106, and the storage hopper 107 The bottom is a shrinking structure; the left side of the support 104 is provided with a lifting platform 2, and the base 101 is provided with an adjustment assembly 3, which cooperates with the lifting platform 2; the le...

Embodiment 2

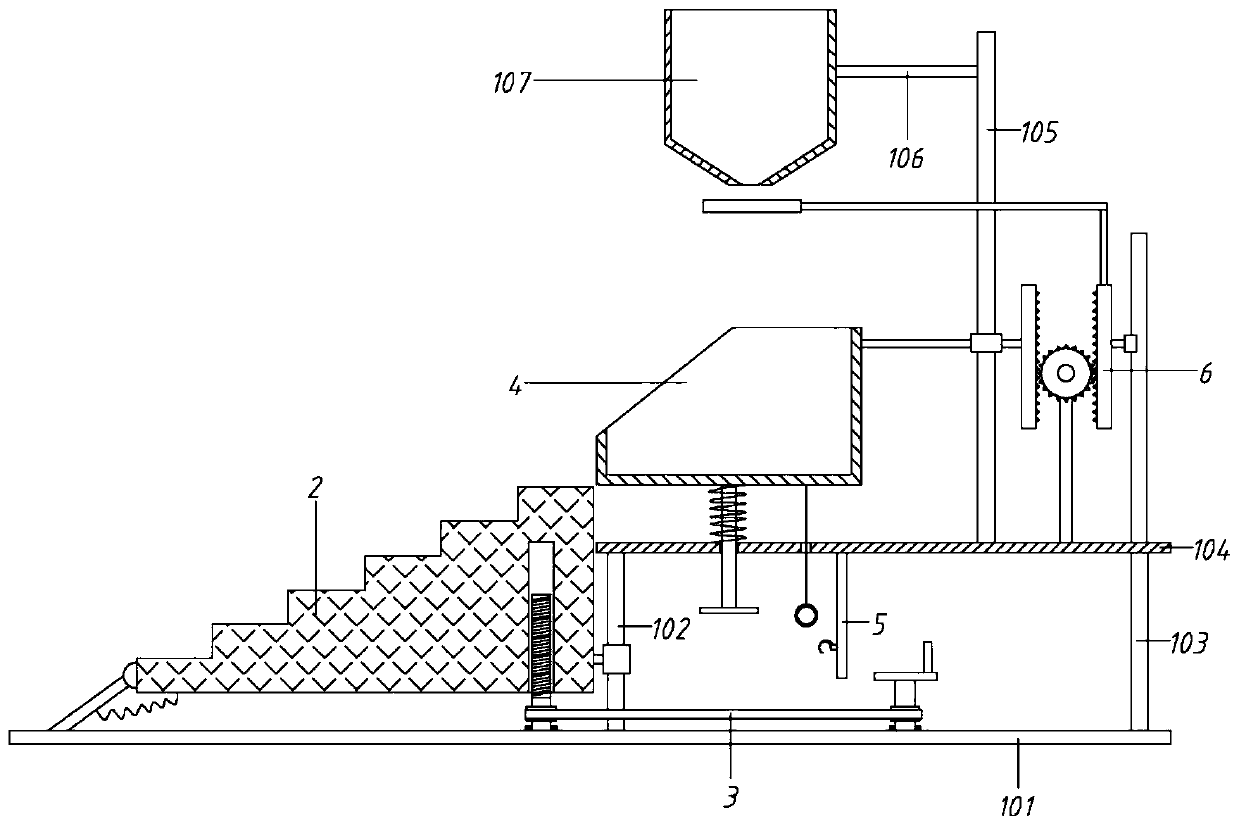

[0064] A breeding feeding machine with a quantitative function, comprising a frame 1, a lifting platform 2, an adjustment assembly 3, a material holding assembly 4, a locking assembly 5 and a blocking assembly 6;

[0065] The frame 1 includes a base 101, a left pole 102, a right pole 103, a support 104, a slide bar 105, a No. 1 connecting rod 106, and a storage hopper 107. The left pole 102 and the right pole 103 are arranged at intervals on the base 101; The top of the left pole 102 and the right pole 103 are connected by a support 104; the middle part of the support 104 is provided with a vertical slide bar 105, and the top of the slide bar 105 is connected with a storage hopper 107 to the left through the No. 1 connecting rod 106, and the storage hopper 107 The bottom is a shrinking structure; the left side of the support 104 is provided with a lifting platform 2, and the base 101 is provided with an adjustment assembly 3, which cooperates with the lifting platform 2; the le...

Embodiment 3

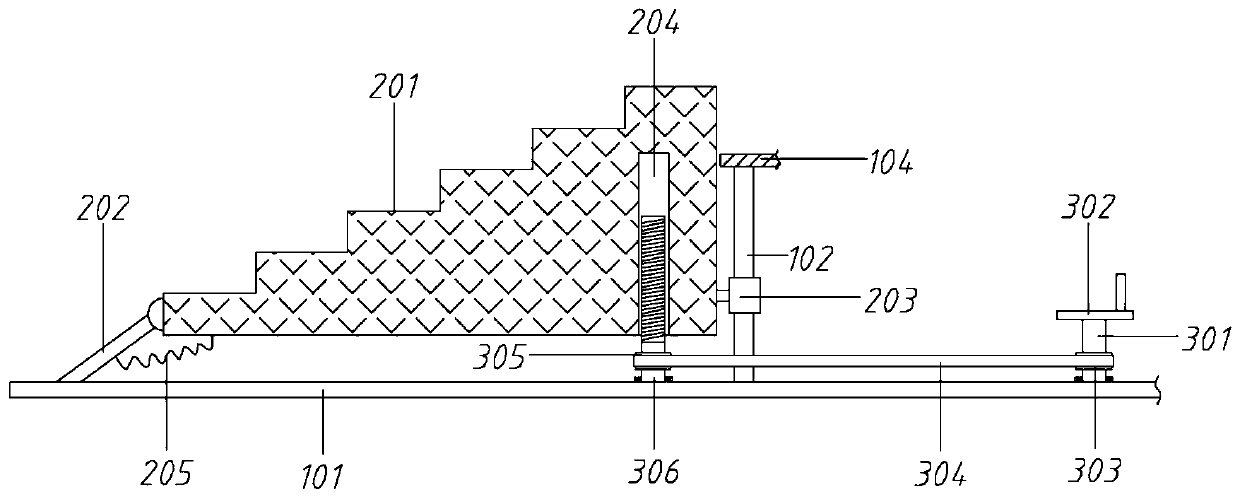

[0081] The difference from Example 2 is that

[0082] The No. 6 connecting rod 608 is a telescopic sleeve rod and is fixed by locking screws; the No. 1 mounting rod 503 is evenly spaced with several hooks 504 from top to bottom.

[0083] Specifically, adjust the telescopic length of the No. 6 connecting rod 608, change the initial height of the blocking plate 609, and then adjust the action range of the blocking assembly 6, and change the single feeding amount of the feeding trough 401. The hooks 504 at different positions are also adapted to the above adjustments, and still realize the functions in the second embodiment.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com