Powder quantitative bagging device

A quantitative bagging and powder technology, applied in packaging, solid materials, transportation and packaging, etc., can solve the problems of difficult control of bagging weight, loss of enterprises, and reduction of bagging efficiency of operators, so as to save weight Program, the effect of improving bagging efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0011] Referring to the accompanying drawings, by describing the embodiments, the specific implementation of the present invention, such as the shape and structure of each component involved, the mutual position and connection relationship between each part, the role and working principle of each part, etc. Further details.

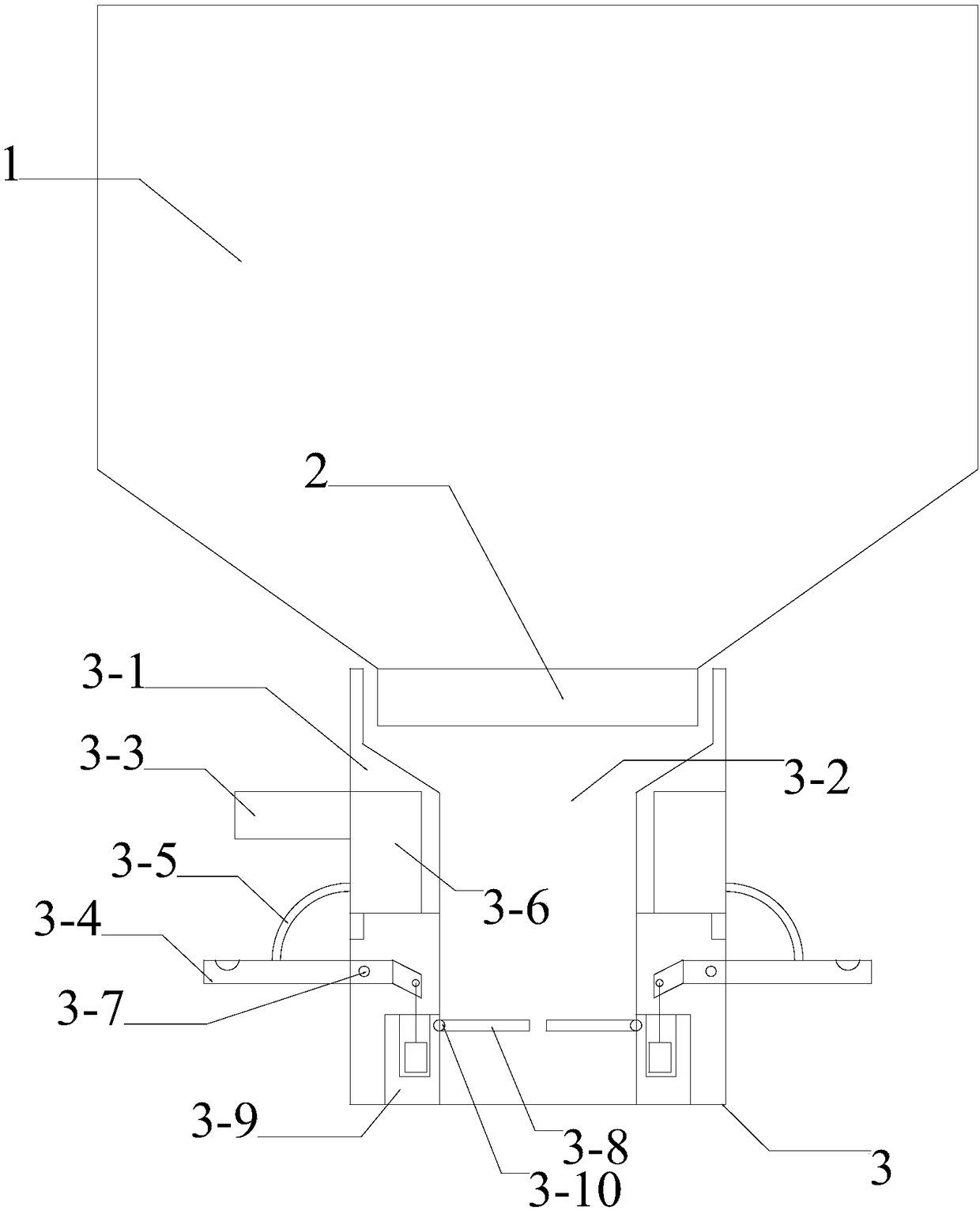

[0012] Such as figure 1 As shown, the present invention provides a powder quantitative bagging device, comprising a powder storage bin 1, a discharge port 2 and a quantitative bagging device 3, the discharge port 2 is arranged at the lower end of the powder storage bin 1, and the powder The body storage bin 1 is connected with the quantitative bagging device 3 through the discharge port 2, and the quantitative bagging device 3 includes a fixed shell 3-1, a discharge channel 3-2, a controller 3-3, and a bag support rod 3-4 , material bag driving connecting rod 3-5, material bag hydraulic controller 3-6, support rod rotating shaft 3-7, sealing material pla...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com