High-fineness ball milling equipment for quartz ceramic processing

A quartz ceramic, high-fineness technology, used in grain processing and other directions, can solve the problems of inconvenient feeding, hinder coarse material grinding, etc., and achieve the effects of preventing accumulation, efficient grinding, and high work efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0026] The subject matter described herein will now be discussed with reference to example implementations. It should be understood that these embodiments are discussed only to enable those skilled in the art to better understand and implement the subject matter described herein, and not to limit the scope of protection, applicability, or examples set forth in the claims. Changes may be made in the function and arrangement of elements discussed without departing from the scope of the description. Various examples may omit, substitute, or add various procedures or components as desired. Additionally, features described with respect to some examples may also be combined in other examples.

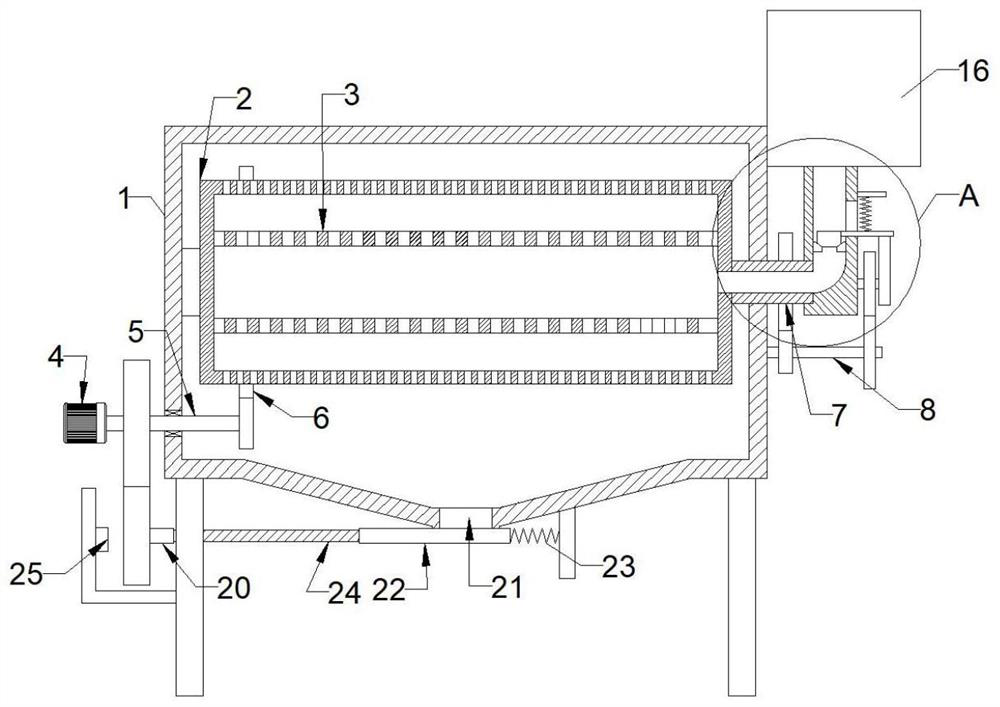

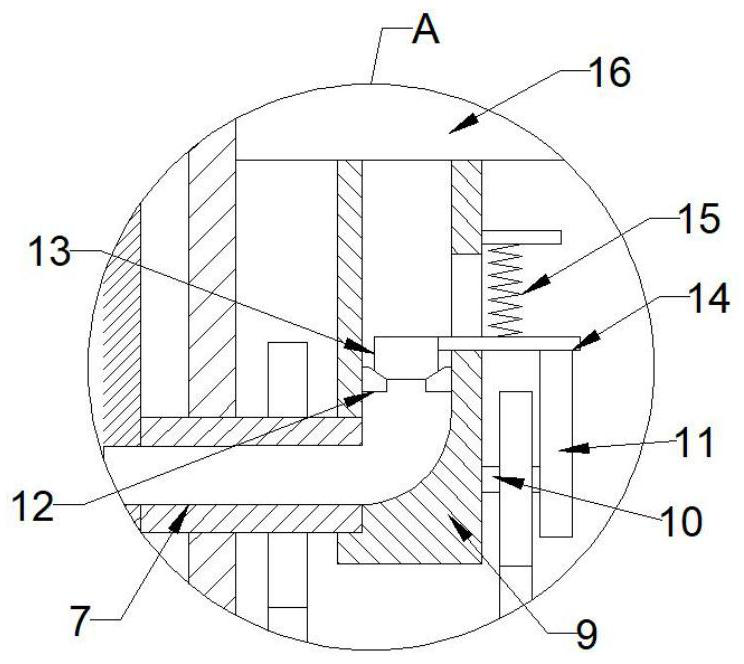

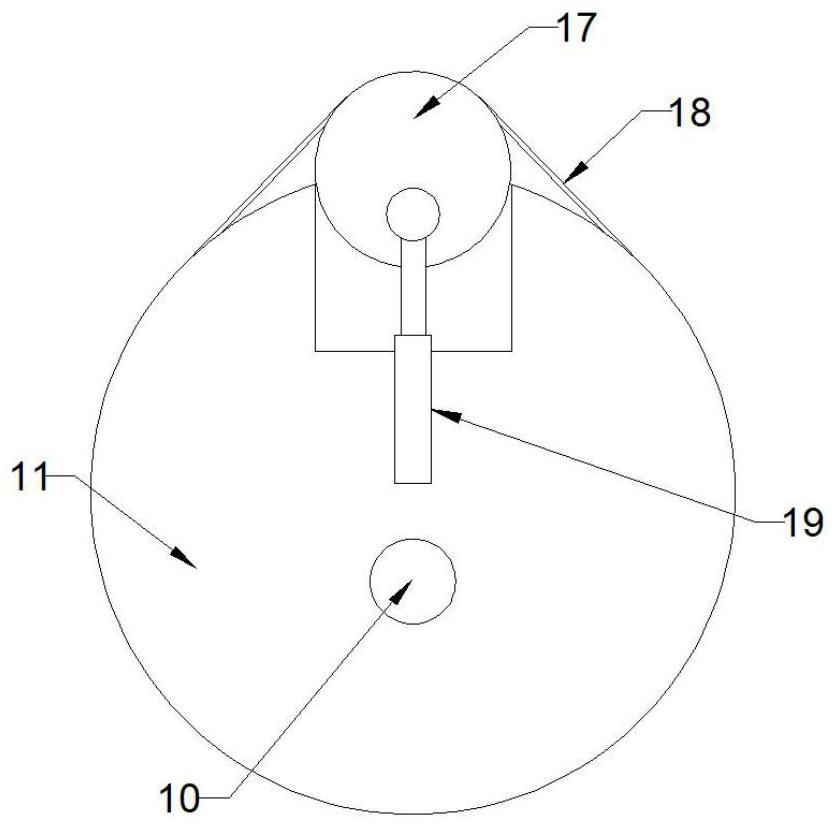

[0027] like Figure 1-2 As shown, a high-fineness ball milling equipment for quartz ceramic processing provided for an embodiment of the present invention includes a work box 1, and a discharge port 21 is opened at the bottom of the work box 1, and also includes:

[0028] The working part ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com