Feeding device for dryer

A drying device and dryer technology, which is applied in drying solid materials, drying cargo handling, application, etc., can solve the problems of resource waste, corruption, deformation of bottom fruits, etc., and achieves a high degree of automation, reduced labor intensity, and less manual participation. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0033] The following will clearly and completely describe the technical solutions in the embodiments of the present invention with reference to the drawings in the embodiments of the present invention.

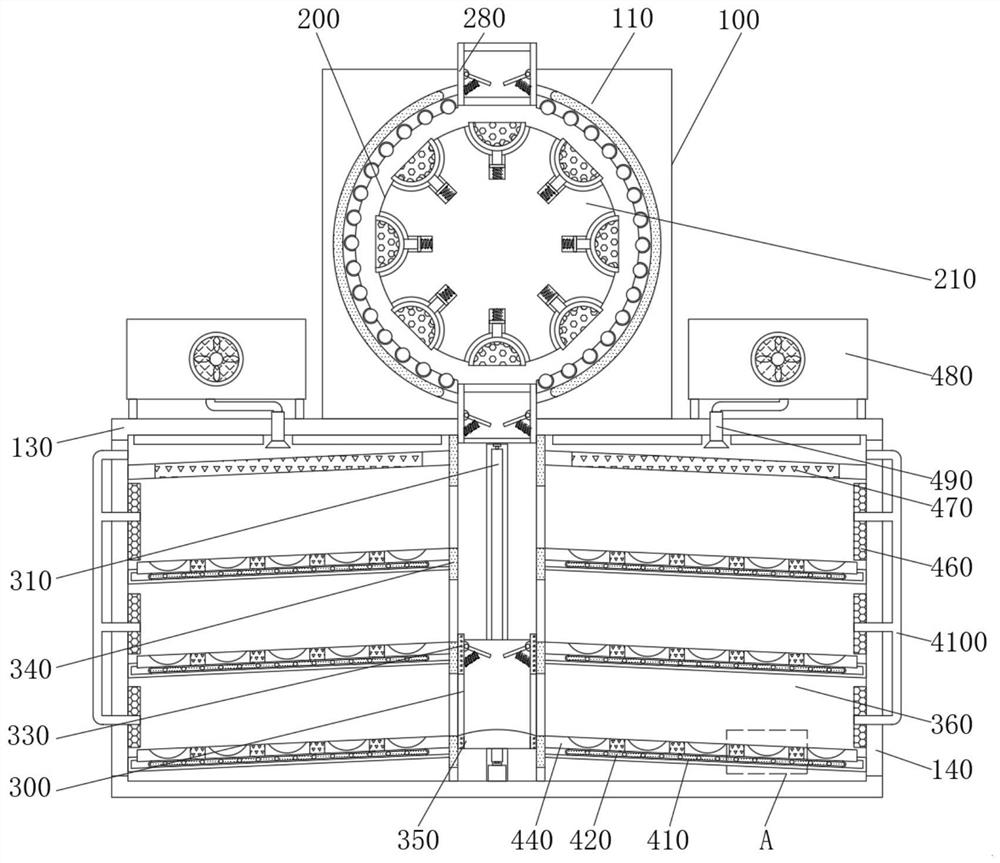

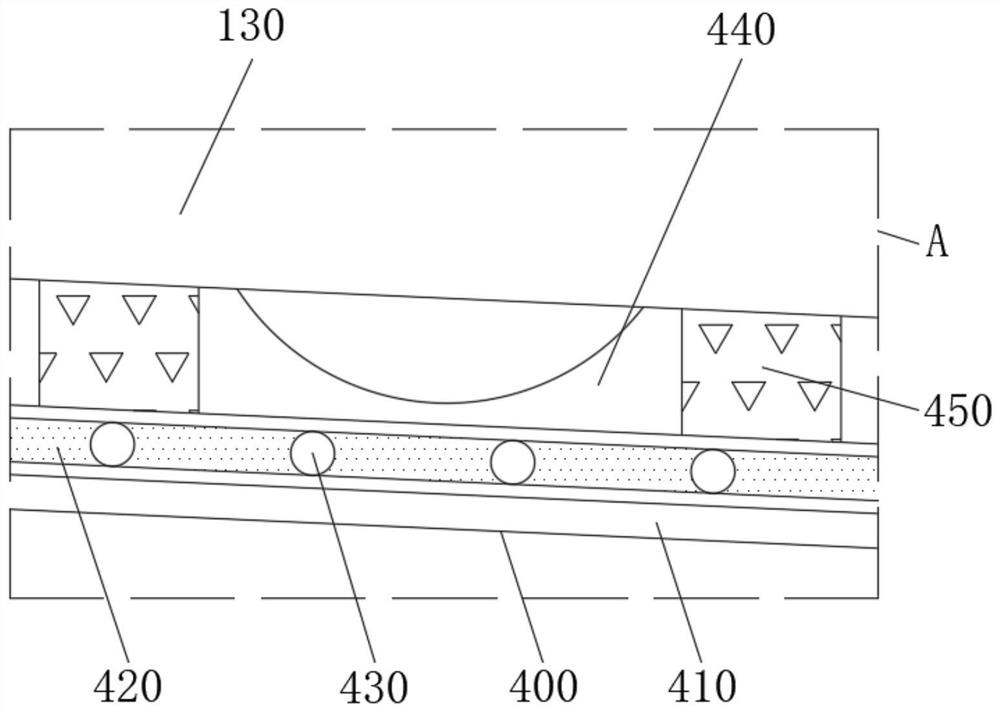

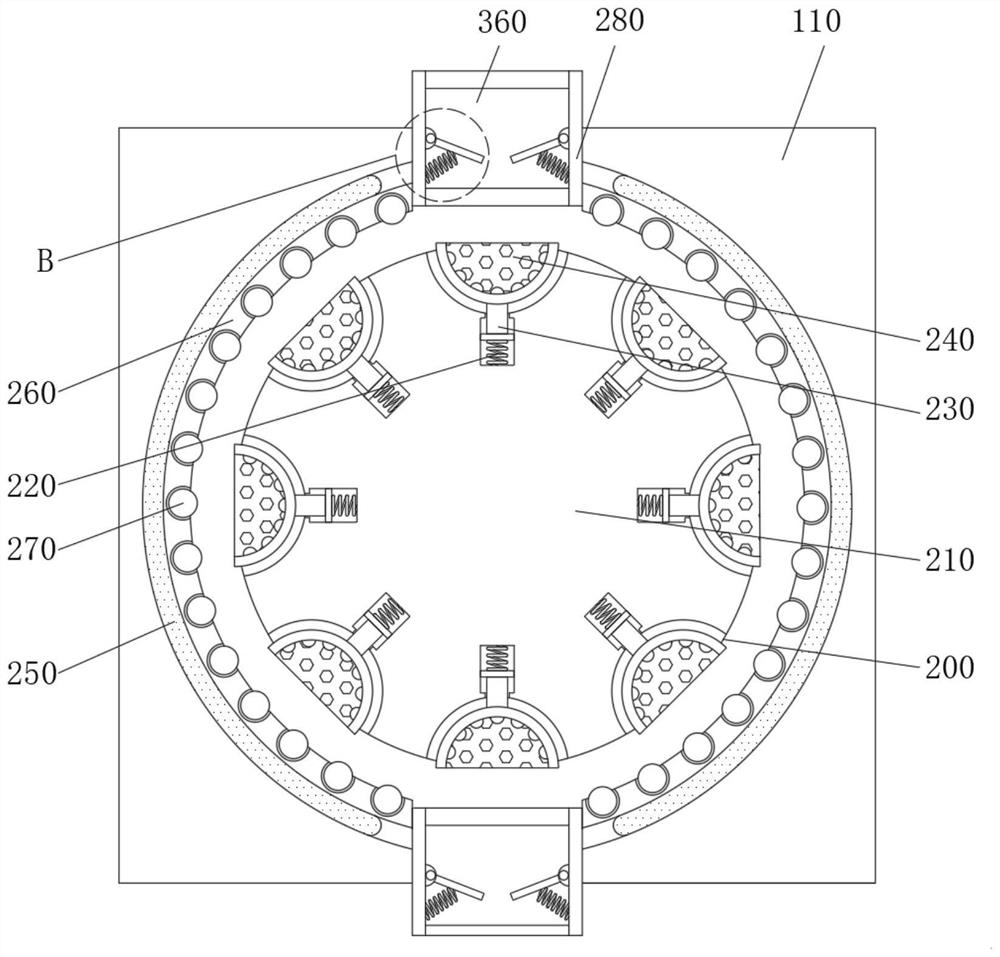

[0034] see Figure 1-7 , an embodiment provided by the present invention:

[0035]A feeding device for a dryer, including a drying device 100, the drying device 100 includes a feeding box 110, a driving mechanism 120, a drying box 130 and a box door 140, and the outer surface of the feeding box 110 is clamped with a driving mechanism 120, which is the current There is a technology, including a motor and a rotating shaft, which drives the rotating shaft to work by controlling the motor, and at the same time the rotating shaft drives the rotating roller 210 to rotate, so as to realize the cutting of fruits and vegetables. The lower surface of the feeding box 110 is fixedly connected with the drying box 130. The left and right sides are all fixedly connected with the box door 14...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com