Aluminum-plastic film cutting device for lithium ion battery

A lithium-ion battery and aluminum-plastic film technology, which is applied in the mechanical field, can solve problems such as poor cutting effect, lack of adjustment and control of cutting distance, and low cutting efficiency of aluminum-plastic film, so as to improve cutting efficiency and cutting efficiency. effect, easy to popularize and apply, simple structure effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

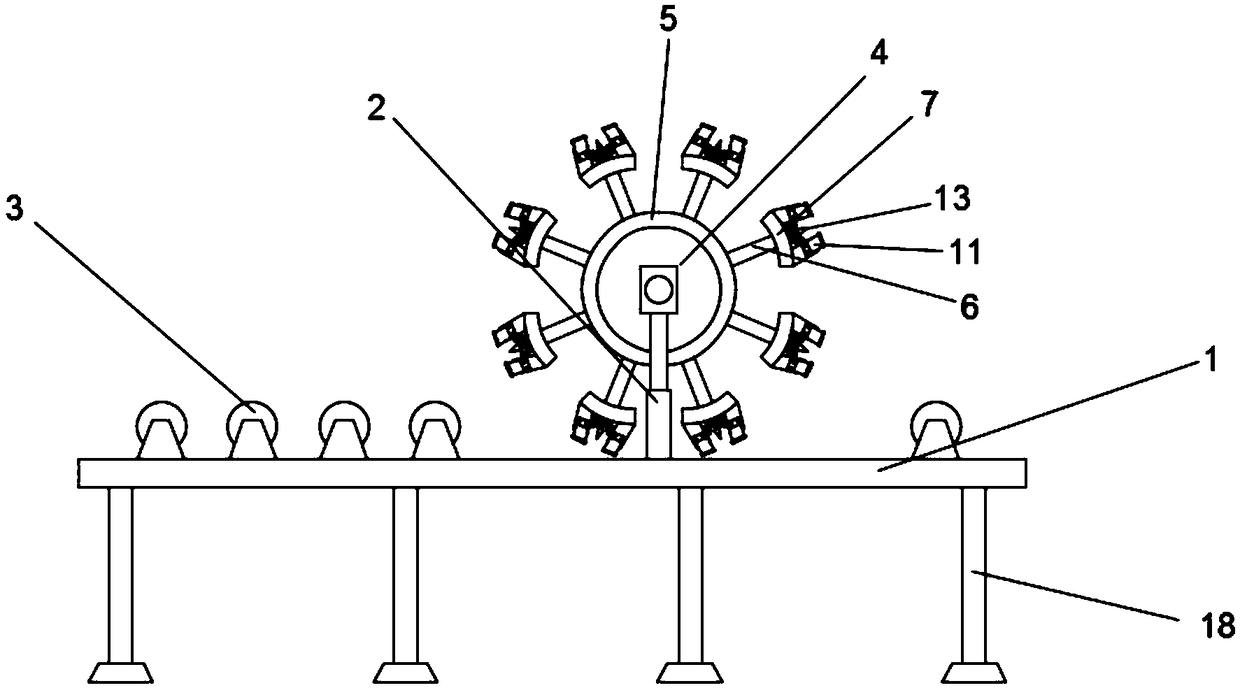

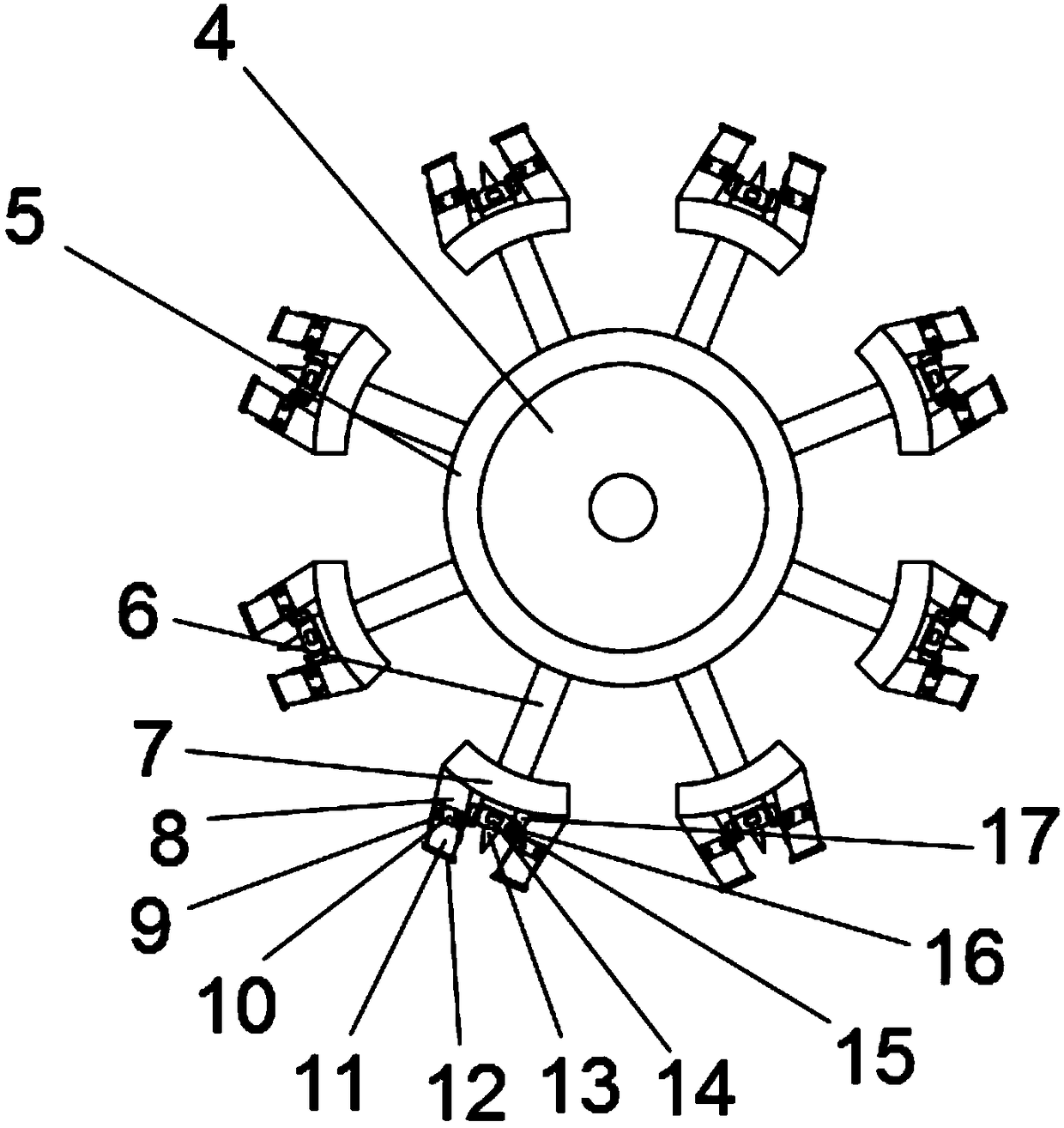

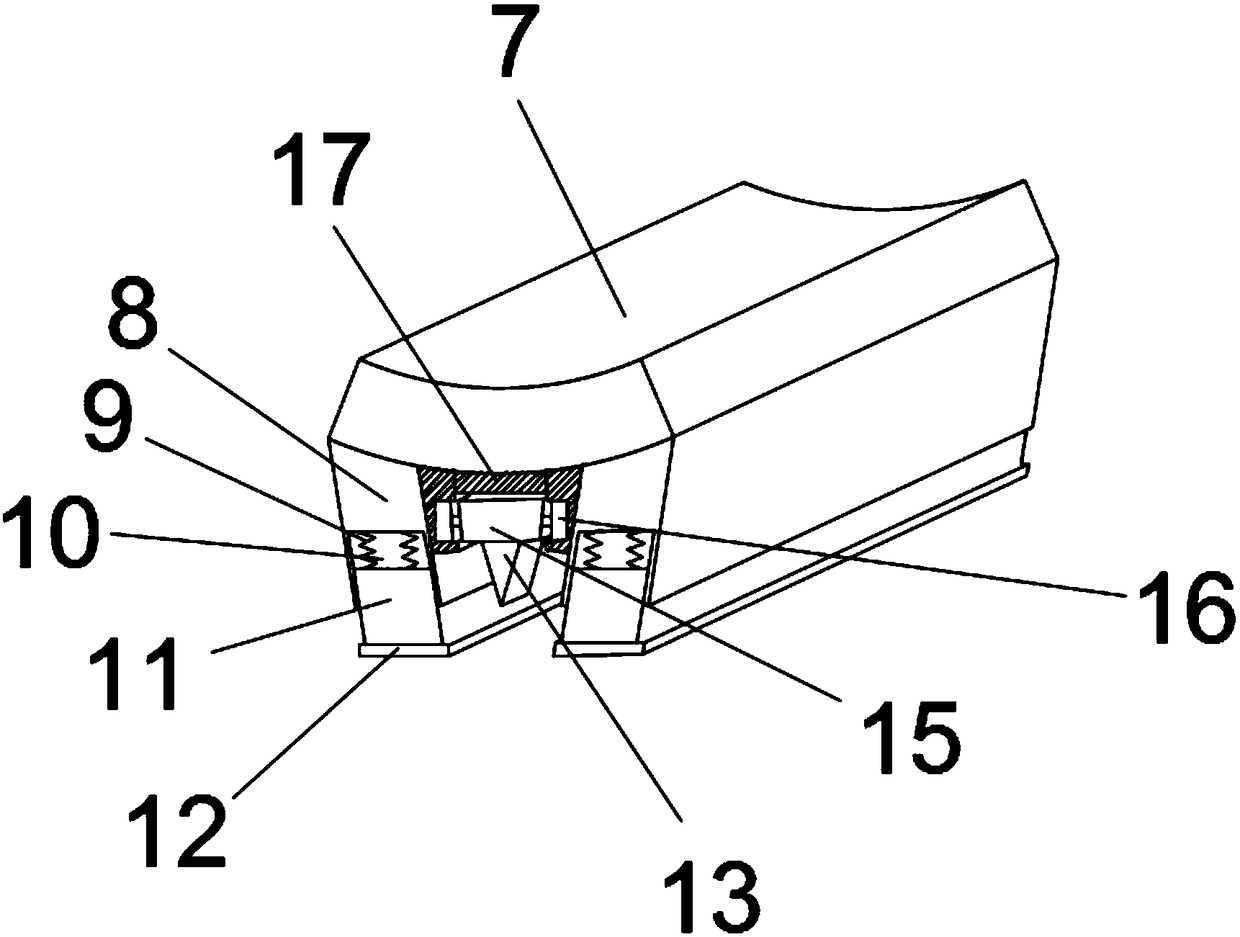

[0017] Embodiment 1: as Figure 1-3 As shown, an aluminum-plastic film cutting device for lithium-ion batteries includes a platform 1, a plurality of conveying rollers 3 are fixedly installed on the top of the platform 1, and a support frame 18 is fixedly connected to the bottom of the platform 1. Two sets of elevating rods 2 are fixedly installed on the top of 1, rotating rollers 4 are rotatably connected between the elevating rods 2, electric push-pull rods 6 are fixedly installed on the side walls of the revolving rollers 4, and one end of the electric push-pull rods 6 An adjusting frame 7 is fixedly connected, and eight groups of the adjusting frame 7 are arranged, and both sides of the rotating roller 3 are fixedly connected with a card edge 5 . The adjustment frame 7 is located between the card edges 5, and the outer wall of the adjustment frame 7 is fixedly connected with two groups of brackets 8, and the bottom of the bracket 8 is provided with a telescopic cavity 10, ...

Embodiment 2

[0018] Embodiment 2: as Figure 1-4 As shown, an aluminum-plastic film cutting device for lithium-ion batteries includes a platform 1, a plurality of conveying rollers 3 are fixedly installed on the top of the platform 1, and a support frame 18 is fixedly connected to the bottom of the platform 1. Two sets of elevating rods 2 are fixedly installed on the top of 1, rotating rollers 4 are rotatably connected between the elevating rods 2, electric push-pull rods 6 are fixedly installed on the side walls of the revolving rollers 4, and one end of the electric push-pull rods 6 An adjusting frame 7 is fixedly connected, and eight groups of the adjusting frame 7 are arranged, and both sides of the rotating roller 3 are fixedly connected with a card edge 5 . The adjustment frame 7 is located between the card edges 5, and the outer wall of the adjustment frame 7 is fixedly connected with two groups of brackets 8, and the bottom of the bracket 8 is provided with a telescopic cavity 10, ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com